Metal hard sealing butterfly valve with moving valve seat

A mobile, hard-sealing technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of valve plate sealing ring and valve seat stuck, valve plate easily stuck, high cost of manufacturing materials, to ensure two-way The effect of sealing performance, simple processing technology and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

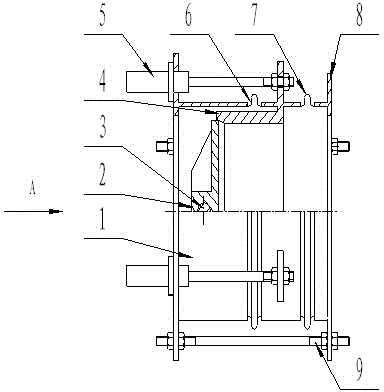

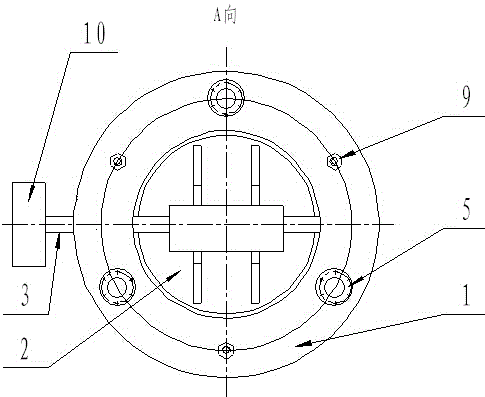

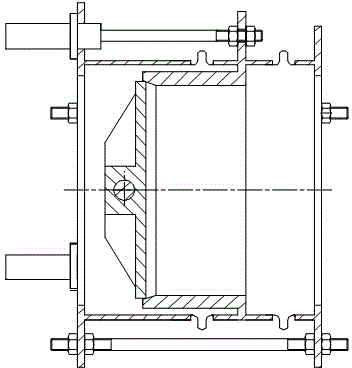

[0026] Such as figure 1 , 2 As shown, this embodiment includes a valve body 1, a valve plate 2, a valve shaft 3, a circular sealing valve seat 4 and a valve plate driving device 10, the valve plate 2 is fixed on the valve shaft 3, and under the action of the valve plate driving device 10, the valve The rotation of the shaft 3 can realize the movement of the switch rotation. The valve plate 2 and the circular sealing valve seat 4 form a spherical or conical metal hard sealing pair. There is a valve body shoulder at the corresponding position, and the valve seat driving device 5 is an oil cylinder, and its two ends are respectively connected with the installation shoulder of the circular sealing valve seat 4 and the valve body shoulder of the valve body 1, and the valve seat driving device 5 The driving effect of the driving action drives the circular sealing valve seat 4 to move left and right along the axis of the valve body, which can realize the compression and separation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com