Juicer

A juicer and driving mechanism technology, applied in the field of juicers, can solve the problems of gears being easily damaged and difficult to clean, and achieve the effects of avoiding the risk of gear damage, smooth cutting of ingredients, and good flow performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

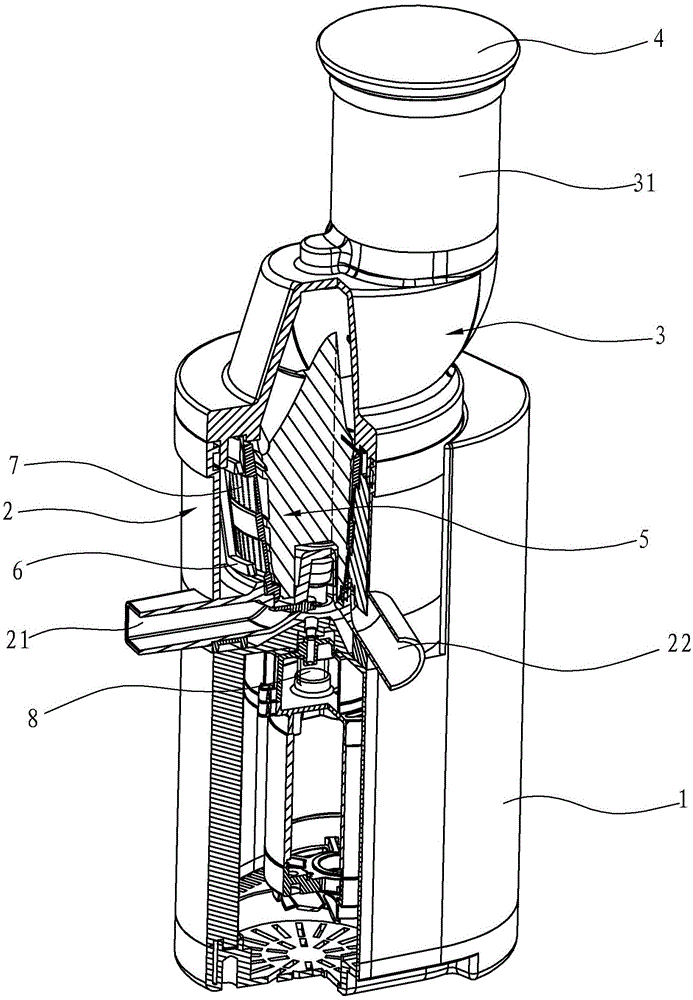

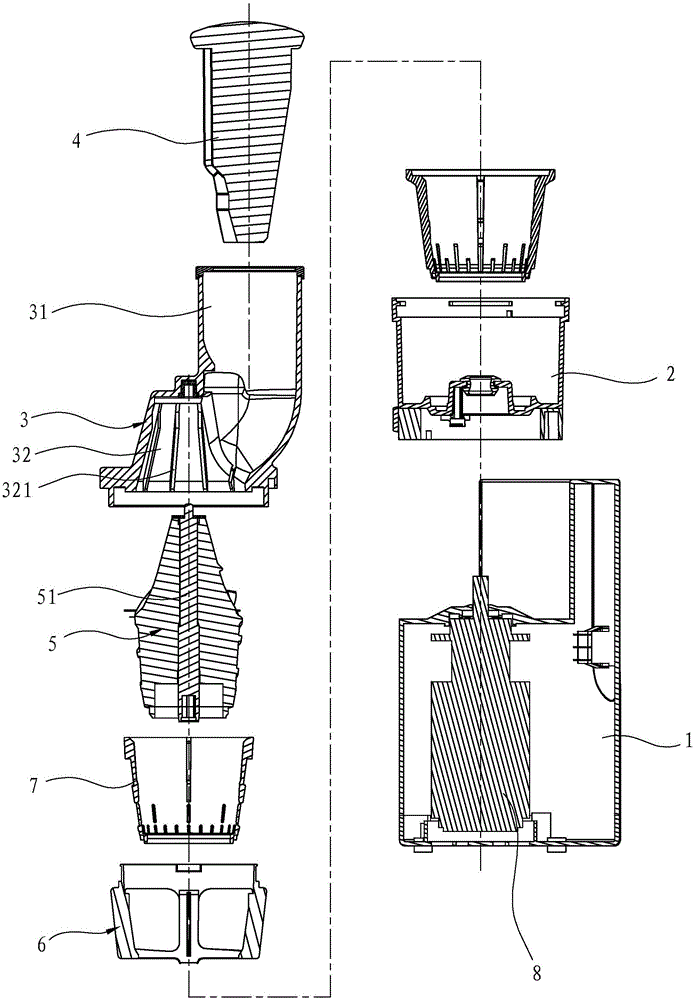

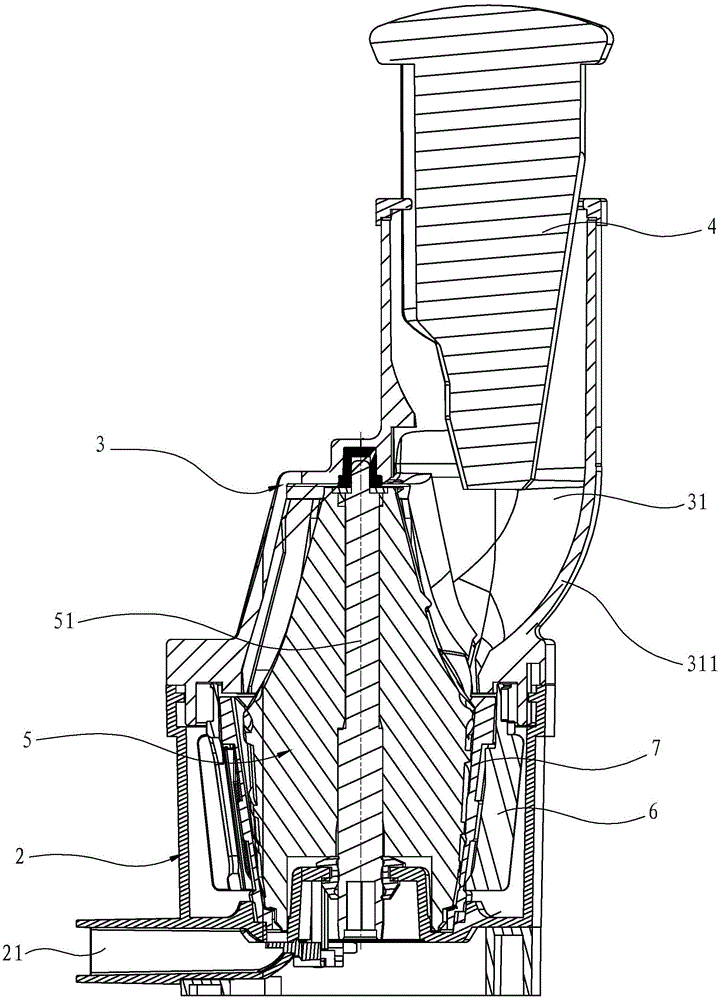

[0032] Such as Figures 1 to 16 As shown, the present invention discloses a juice machine, which includes a base 1 , a driving mechanism 8 , a cup cover 3 , a casing 2 , a filtering device 7 , an extruding rod part 5 , a net brush 6 and a pushing rod 4 .

[0033] Wherein, the driving mechanism 8 is arranged in the base 1, and the housing 2 is arranged on the base 1. The bottom of the housing 2 has a slag collection tank and a juice collection tank, and a juice outlet pipe 22 communicating with the juice collection tank extends outside the housing 2. And the slag discharge pipe 21 communicating with the slag collection tank, the cup cover 3 is arranged above the shell 2, the cup cover 3 has a cup cover inner cavity 32, and the scrap ribs 321 are arranged on the cup cover inner cavity 32 The cup cover 3 is provided with a feed channel 31 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com