Material conveying conversion frame

A conveying conversion and conveying rack technology, which is used in metal processing equipment, auxiliary welding equipment, welding equipment, etc., can solve the problems of lack of effective positioning devices for tooling racks, difficult to guarantee positioning accuracy, and long consumption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

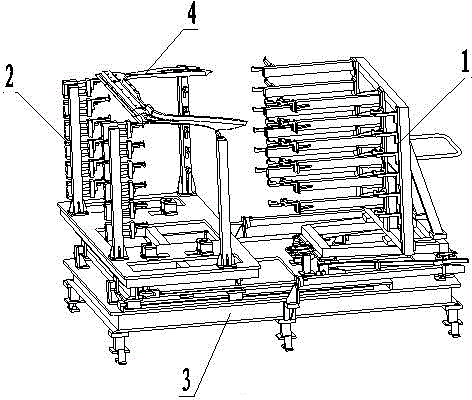

[0026] Referring to Figure 1, the present invention includes a material conveying rack 1, a material receiving rack 2 and a BASE reference board 3. The material conveying rack 1 and the material receiving rack 2 are both located on the BASE reference board 3, and are respectively arranged on the left and right sides of the BASE reference board 3. At both ends, the BASE reference board 3 is fixed on the horizontal ground.

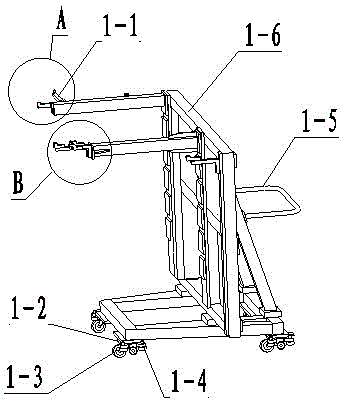

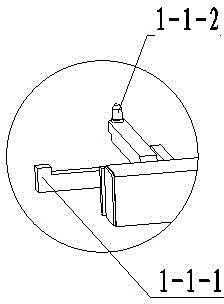

[0027] Refer to Figure 1. figure 2 , image 3 , Figure 4 , The material conveying rack 1 of the present invention includes a material conveying rack frame 1-6, a material conveying support and positioning assembly, a material conveying rack positioning block 1-2, rollers 1-3, pulleys 1-4 and handrails 1-5. The material conveying frame frame 1-6 is composed of a horizontal underframe and a vertical frame. The material conveying support and positioning assembly includes a material conveying support block 1-1-1 and a material conveying positioning pin 1-1-2, thei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com