De-enzyming method for star anise

A star anise and greening technology, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of oil content and aroma loss, etc., and achieve the effect of reducing oil loss, lasting fragrance of finished products, and being convenient for long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

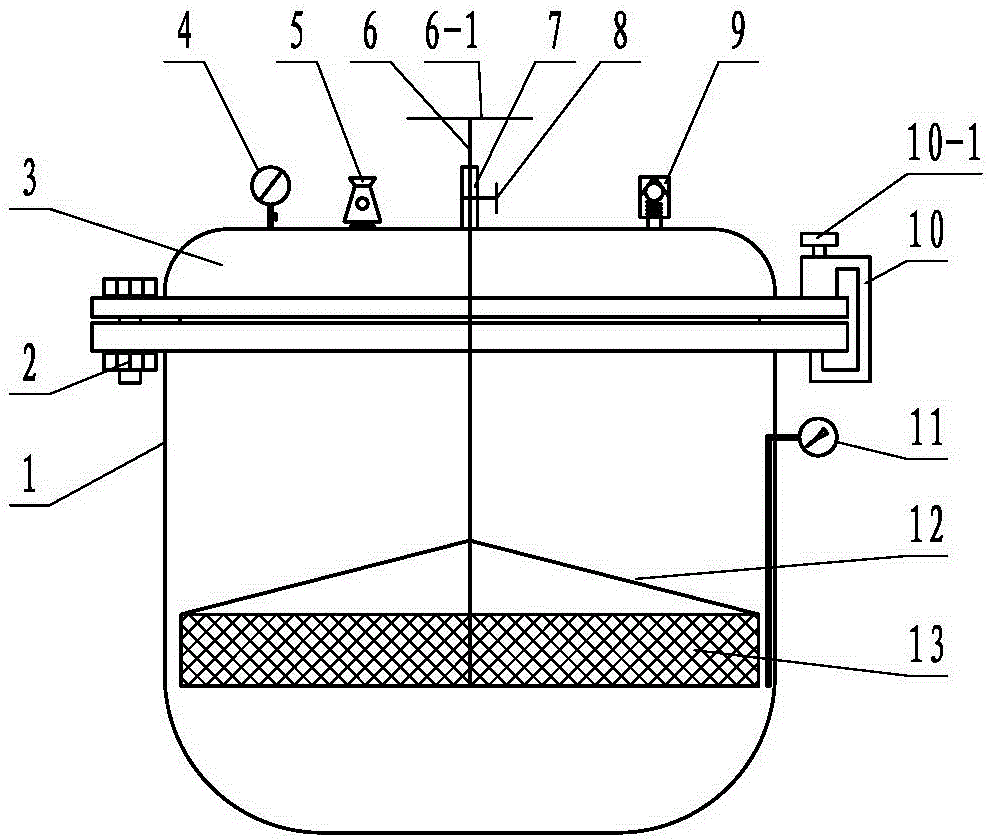

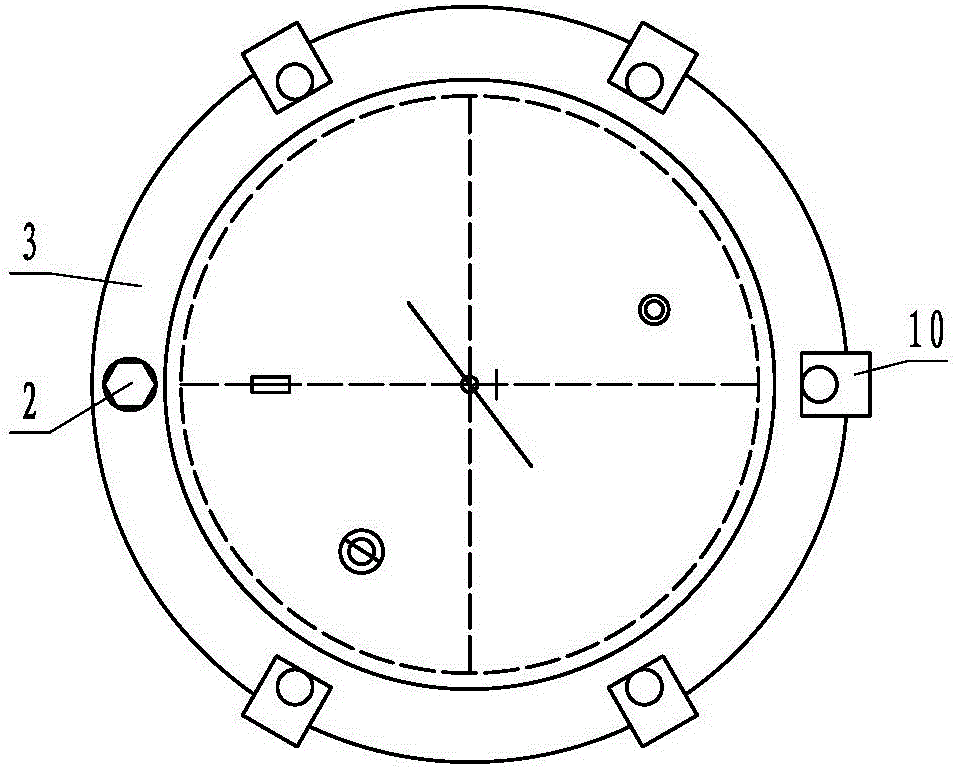

[0027] The greening method of the star anise of the present embodiment may further comprise the steps:

[0028] A. After heating the water to boiling, put the star anise into the tray in the pressure vessel and steam it over water;

[0029] B. Continue to heat, keep the pressure of the pressure vessel at 0.1-0.2KPa, when the temperature in the pressure vessel reaches 110-120°C, lower the tray containing star anise into the hot water in the pressure vessel;

[0030] C. Under the condition of pressure of 0.1-0.2KPa, keep warm and cook for 3 minutes, lift the tray away from the hot water for a certain distance through the pull rod connected to the tray, exhaust immediately, open the cover, and pour out the star anise;

[0031] D. Place the star anise obtained in step C in the air in a ventilated place or dry in a dryer to a substantially constant weight.

Embodiment 2

[0033] The greening method of the star anise of the present embodiment may further comprise the steps:

[0034] A. After heating the water to boiling, put the star anise into the tray in the pressure vessel and steam it over water;

[0035] B. Continue heating, keep the pressure of the pressure vessel at 0.2-0.3KPa, when the temperature in the pressure vessel reaches 120-130°C, drop the tray with star anise into the hot water in the pressure vessel;

[0036] C. Under the condition of pressure of 0.2-0.3KPa, keep warm and cook for 2 minutes, lift the tray away from the hot water for a certain distance through the pull rod connected to the tray, exhaust immediately, open the cover, and pour out the star anise;

[0037] D. Place the star anise obtained in step C in the air in a ventilated place or dry in a dryer to a substantially constant weight.

Embodiment 3

[0039] The greening method of the star anise of the present embodiment may further comprise the steps:

[0040] A. After heating the water to boiling, put the star anise into the tray in the pressure vessel and steam it over water;

[0041] B. Continue heating, keep the pressure of the pressure vessel at 0.3-0.4KPa, when the temperature in the pressure vessel reaches 130-140°C, lower the tray with star anise into the hot water in the pressure vessel;

[0042] C. Under the condition of pressure of 0.3-0.4KPa, keep warm and cook for 0.5 minutes, lift the tray away from the hot water by a certain distance through the tie rod connected to the tray, exhaust immediately, open the cover, and pour out the star anise;

[0043] D. Place the star anise obtained in step C in the air in a ventilated place or dry in a dryer to a substantially constant weight.

[0044] The oil content of dried star anise is tested to obtain the following data:

[0045] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com