A lubricating flow guide structure for a dual-clutch transmission

A dual-clutch, clutch technology, applied in the direction of gear lubrication/cooling, transmission parts, components with teeth, etc., can solve the problem that the shaft end bearing and the center oil passage are not considered to supply oil separately, and it is not suitable for special dual-clutch transmissions. The structure and the source of lubricating oil are not explained, so as to achieve the effect of simple structure, avoiding pressure lubricating oil passage, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

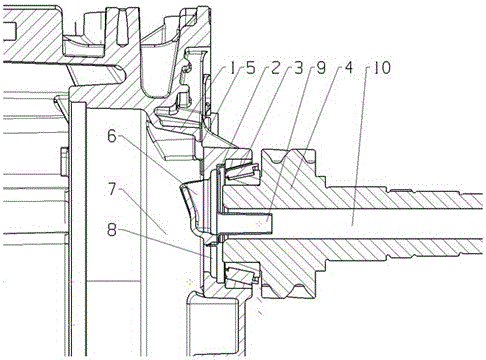

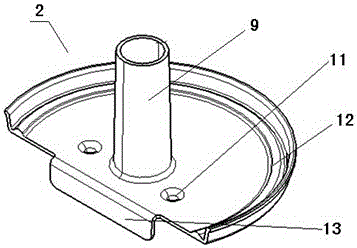

[0018] see figure 1 The shown lubricating and diverting structure of a dual clutch transmission includes a clutch case 1, a shaft end bearing 3 that is connected to the clutch case and corresponds to the clutch installation cavity 7, and a drive shaft 4 whose left end is mated with the shaft end bearing , its prominent substantive features are: the transmission shaft 4 is provided with a central oil passage 10 passing through the axis line and a plurality of small lubricating holes (not shown in the figure) communicating with the central oil passage, so that the lubricating oil passes through many The two lubricating holes respectively reach the parts that need to be lubricated; on the left side of the shaft end bearing 3, there is a guide member 2, which communicates with the central oil passage 10 of the transmission shaft 4; The upper part of the flow guiding membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com