Environmentally-friendly easy tearing protection adhesive tape and production method thereof

A protective tape, environmentally friendly technology, used in adhesives, film/sheet adhesives, pretreated surfaces, etc., can solve the problems of poor wear resistance, poor holding force, difficult to remove, etc., and achieves convenient and safe operation. Easy to use and safe, improve the effect of market competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An environmentally friendly easy-to-tear protective tape,

[0041] Formula: PE plastic particles, plastic filler particles CH-808, gauze, water-based silicon, glue, of which PE plastic particles 38%, plastic filler particles CH-80816%, gauze warp 2.4%, gauze weft 3.6%, water-based silicon ( Water 1.2%, silicon 0.8%), acrylic glue (water 19%, glue 19%).

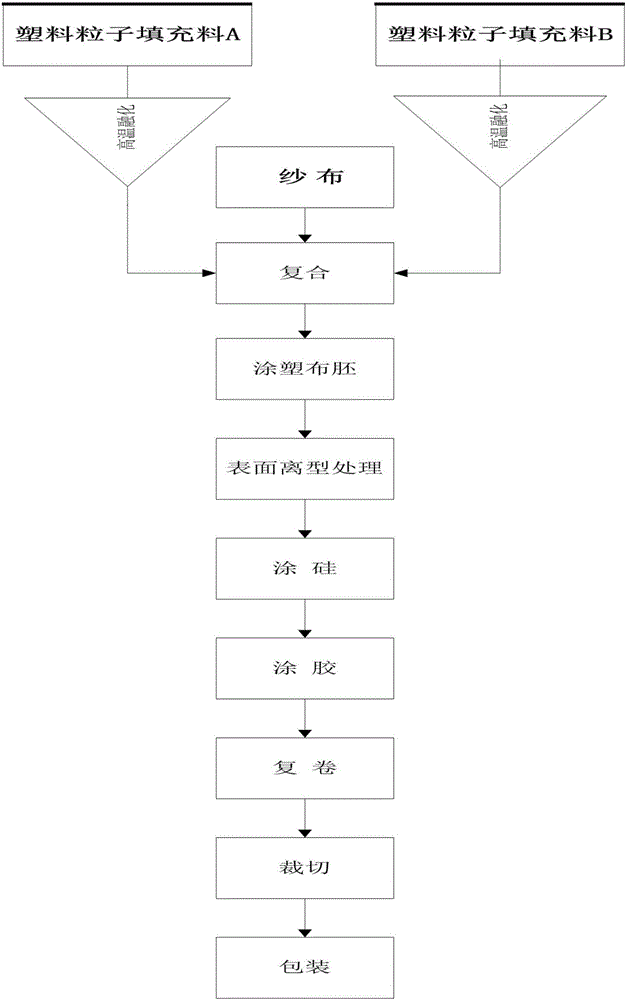

[0042] The preparation process is as follows:

[0043] (1) Stir PE plastic particles and plastic filler particles CH-808 evenly, then add the screw to mix at a high temperature of 260°C-300°C, melt and compound with gauze to form a plastic-coated double-sided cloth embryo;

[0044] (2) Add the environmentally friendly water-based silicon used for surface release treatment into the trough, drive the cloth to rotate through the anilox roller in the trough, and evenly apply a layer of environmentally friendly silicon on the plastic-coated surface of the coated embryo. Water-based silicon is dried in a 90°C-100°C drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com