Water-developable photopolymerization type lithographic printing material containing two photosensitive layers and application thereof

A lithographic printing plate and photosensitive layer technology, which is applied in the direction of printing, preparation of printing surface, photoplate making process of pattern surface, etc., can solve problems such as dirty plate and polluting printing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

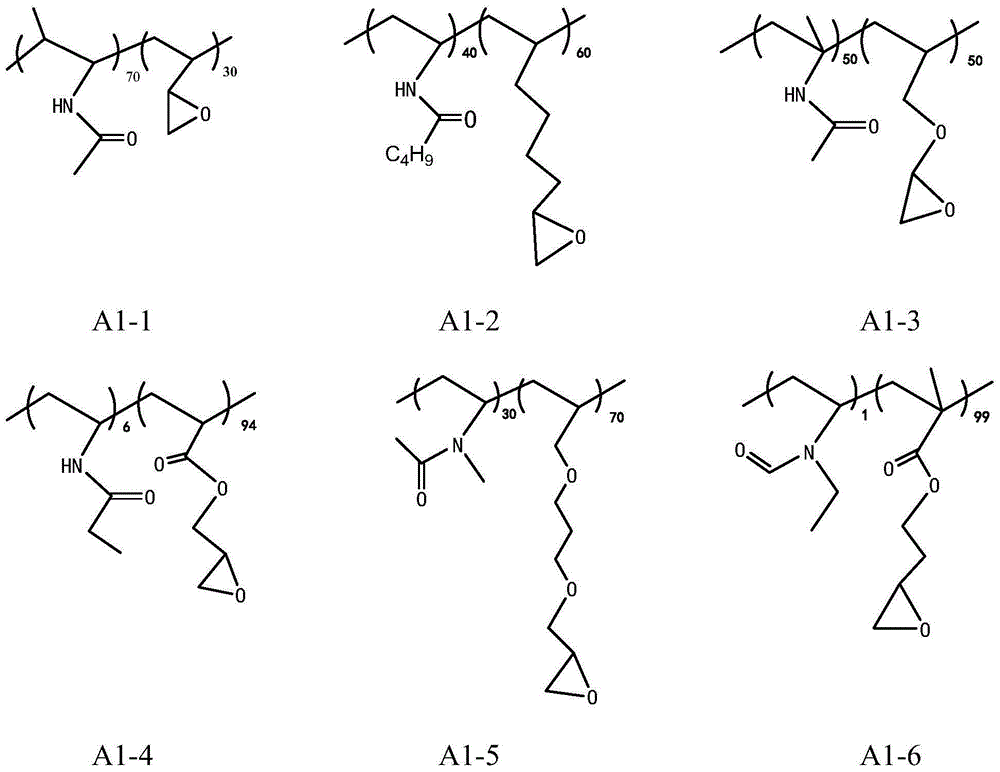

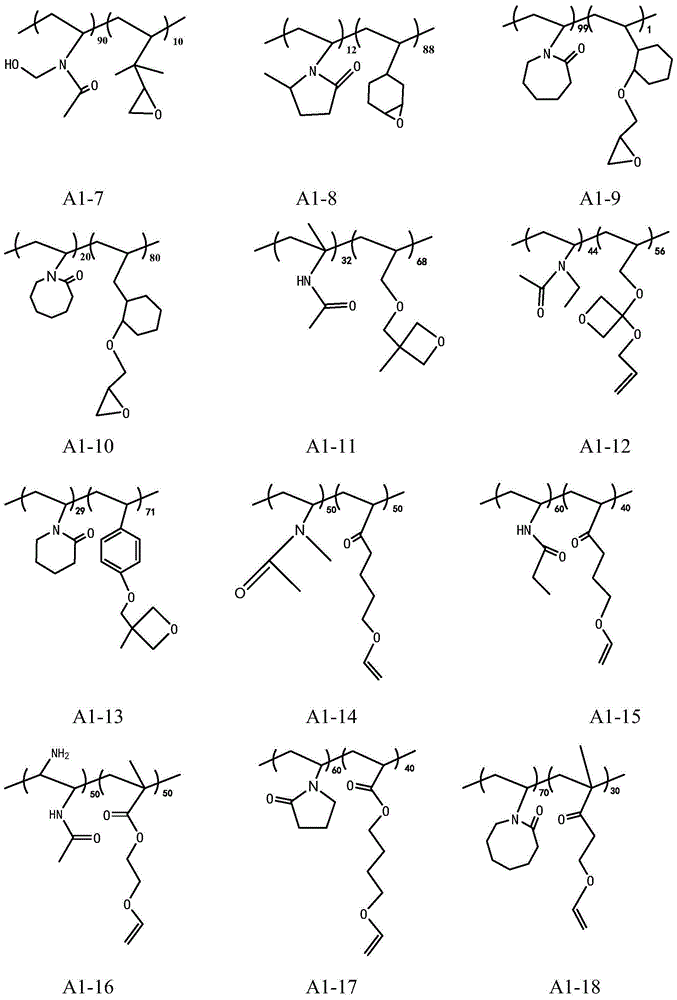

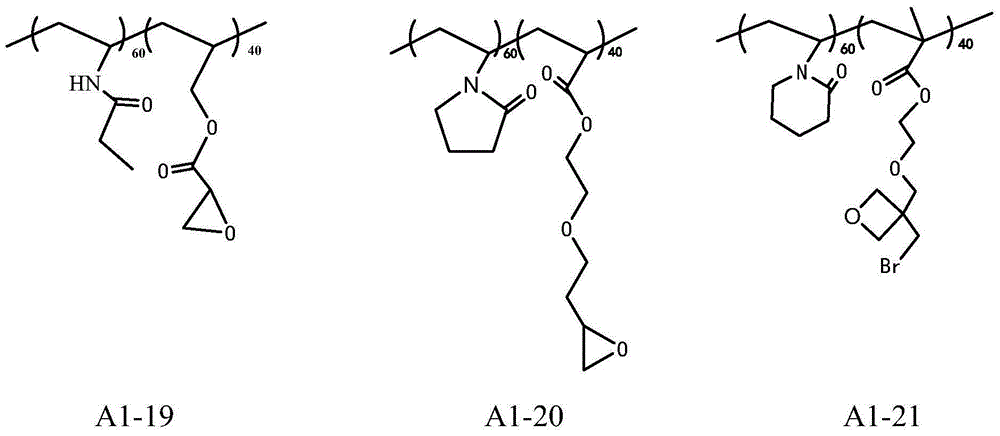

Method used

Image

Examples

Embodiment 1-20 and comparative example 1-11

[0094] Support

[0095] Use pre-treated aluminum substrates that meet the following conditions:

[0096] Aluminum base size: 1030mm×800mm

[0097] Aluminum base thickness: 0.28-0.3mm

[0098] Sand mesh specification: R a =0.5-0.6μm

[0099] R h =0.3-0.35μm

[0100] Anodized film weight: 3.0-3.5g / m 2

[0101] Photosensitive hydrophilic bottom layer

[0102] Using the above-mentioned support body, extrusion-coat the photosensitive hydrophilic bottom layer coating solution represented by the following formula on the support body, so that the coating dry mass of the photosensitive hydrophilic bottom layer is 0.02 g / m 2 , and dried in a blast oven at 100°C for 1 minute.

[0103] Photosensitive Hydrophilic Primer Coating Liquid Formula

[0104]

[0105] lipophilic photosensitive layer

[0106] Extrusion-coat the following lipophilic photosensitive layer coating solution on the photosensitive hydrophilic bottom layer prepared as above, so that the coating dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com