Numerical control five-shaft motion bridge type stone cutter

A five-axis linkage and stone cutting machine technology, which is applied in stone processing equipment, working accessories, manufacturing tools, etc., can solve the problems of inconvenient loading and unloading of workpieces, poor machining accuracy, etc., achieve efficiency improvement, stable operation, and reduce production and equipment maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments.

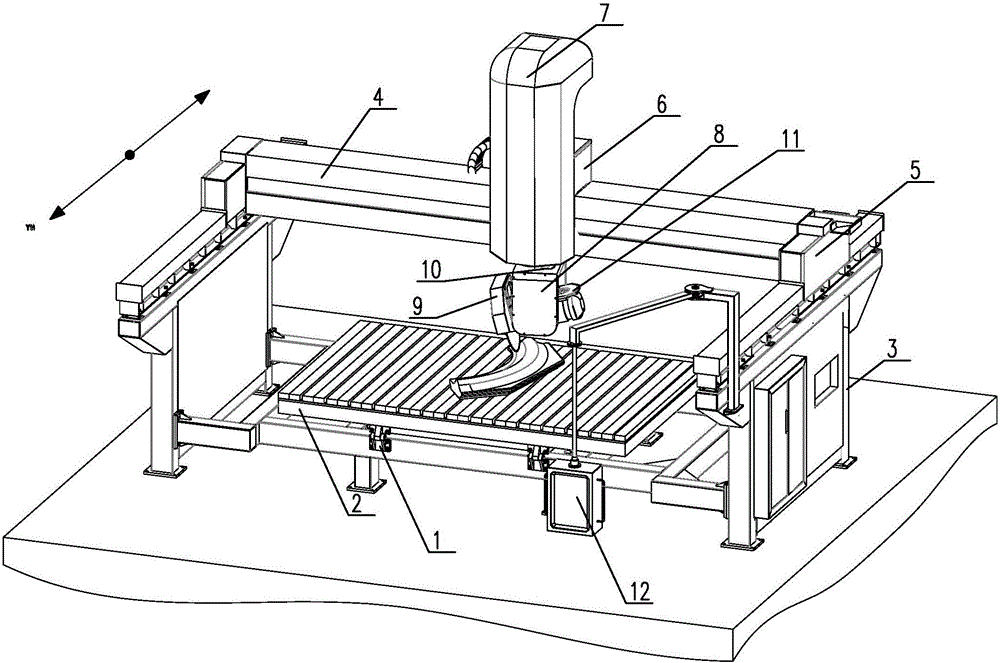

[0016] refer to Figure 1 to Figure 3 As shown, the CNC five-axis linkage bridge stone cutter includes a base 1, a workbench 2, a side frame 3, a beam 4, a longitudinal travel mechanism 5, a horizontal travel mechanism 6, a lifting and cutting mechanism 7, a cutting linkage seat 8, and a cutting device 9 , C-axis rotary drive mechanism 10, A-axis rotary drive mechanism 11, PC industrial control operation box 12;

[0017] The workbench 2 is hinged on the base 1 and can rotate 0-85° around the base 1. The workbench 2 includes a workbench panel 21 and a turning hinge 22. The workbench panel 21 is evenly provided with a plurality of chip removal grooves 211. The turning over One side of the hinge 22 is fixed on the frame base 1, and the other side is connected with the bottom surface of the workbench panel;

[0018] There are two side frames 3, which are arranged symmetrically on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com