Small-power laser hybrid cutter and using method thereof

A low-power, laser cutting technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of the promotion of laser cutting machines, increase production costs and maintenance costs, and limit the scope of later use of laser cutting machines. Achieve the effect of retaining use value, promoting update and improvement, and improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

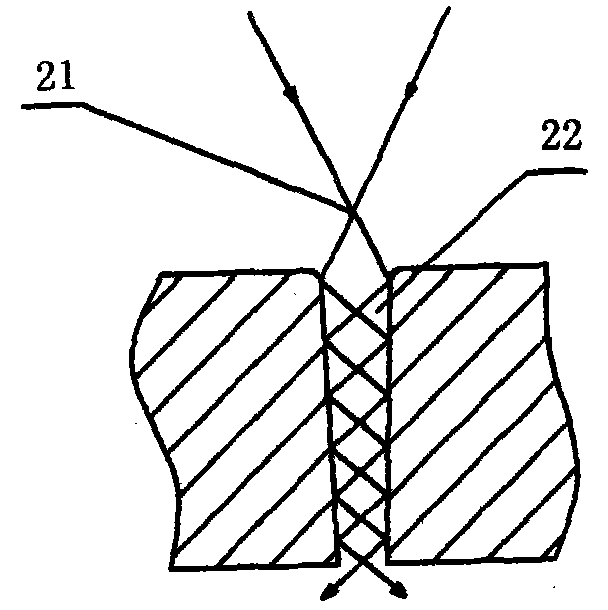

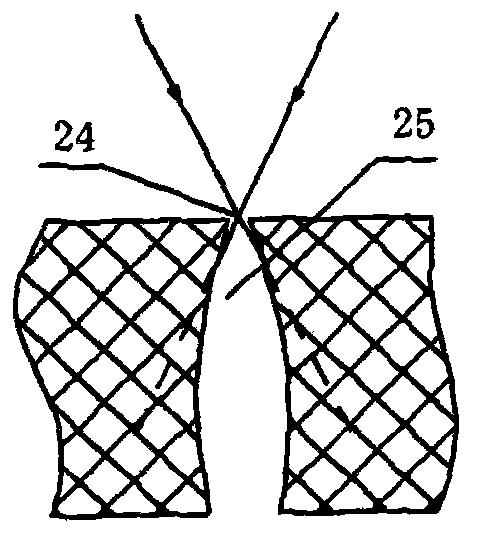

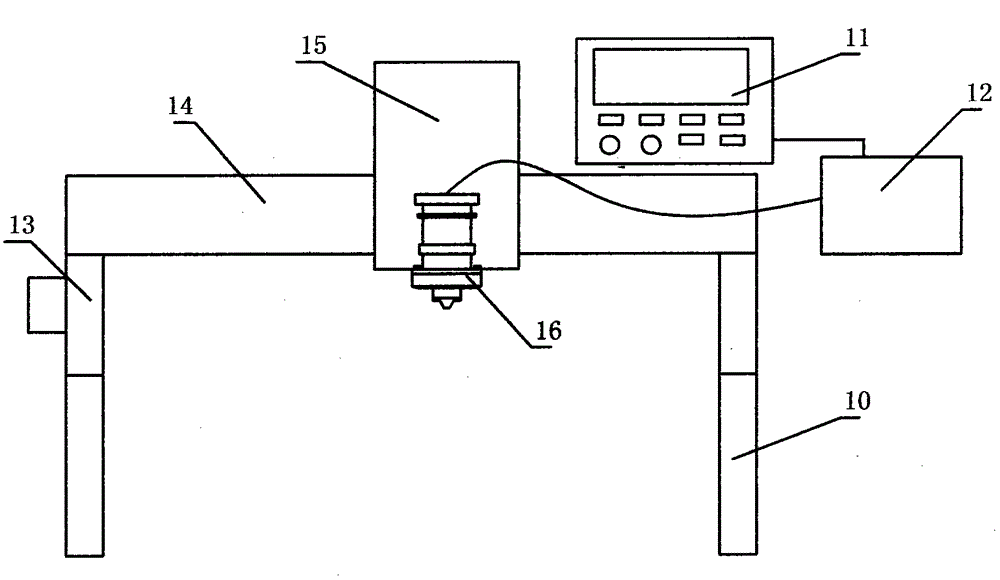

[0037] Attached below image 3 , Figure 4 Further description of the low-power laser mixed cutting machine described in the present invention:

[0038] The low-power laser mixed cutting machine of the present invention includes a base 10, a controller 11, a laser cutting gun 16, a laser generator 12, a Y-axis transmission system 13 located on the base 10, and an X axis located on the Y-axis transmission system 13. A shaft transmission system 14 and a Z-axis follow-up system 15 connected to the X-axis transmission system 14 . Among them, the controller 11 is the control and input center of the entire machine, the X-axis transmission system 14 and the Y-axis transmission system 13 are all slider and guide rail transmission mechanisms driven by the motor, and the Z-axis follow-up system 15 is controlled by the controller 11. A follow-up lifting system that automatically realizes the distance adjustment between the cutting head and the metal plate to be cut by detecting the cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com