Pitch pre-treating and dispersing device with weighing function

A technology of dispersing device and pretreatment, which is applied in mixers, dissolving, mixers, etc. with rotary stirring devices, can solve the problems of slow feeding speed of materials, affecting the mixing effect of asphalt, reducing the quality of asphalt, etc., and achieving better results. , Improve the mixing effect, improve the effect of the workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

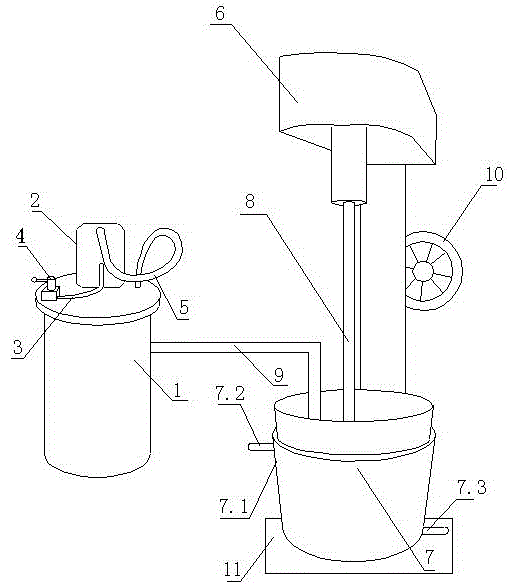

[0012] see figure 1 with figure 2 , the present invention relates to an asphalt pretreatment and dispersing device with a weighing function, comprising a mixing tank 1, a mixer 6, and a mixing tank 7, the top of the mixing tank 1 is fixed with a pneumatic pump 2, and the pneumatic pump 2 The liquid inlet is communicated with the inside of the mixing tank 1 through the oil outlet pipe 3, and the oil outlet pipe 3 is equipped with a control valve 4, and the control valve 4 is used to control the oil outlet pipe 3 to supply oil to the pneumatic pump 2. The liquid outlet of the pneumatic pump 2 is connected to the oil hole on the top of the mixing tank 1 through the oil return pipe 5 .

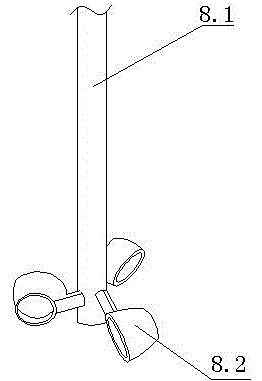

[0013] Described mixer 6 is arranged on the top of mixing tank 7, and above mixing tank 7 is provided with dispersing device 8, and the top of this dispersing device 8 is connected with mixer 6, is used for stirring the material in mixing tank 7, and this dispersing device 8 It is a telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com