Shielding film, shielding circuit board and terminal device

A technology for shielding circuits and shielding films, applied in circuit devices, printed circuit parts, magnetic field/electric field shielding, etc., can solve the problems of gaps in pins, electromagnetic leakage, difficulty in adapting to ultra-thin design requirements, etc., to reduce the thickness , the effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

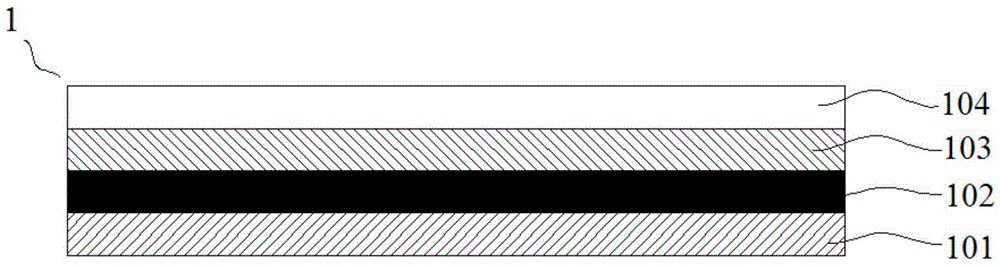

[0037] refer to figure 2 , figure 2 It is a specific embodiment of the shielding film in the embodiment of the present invention. The shielding film 1 described in this embodiment includes a first insulating layer 101 and a shielding layer 102. The shielding layer 102 is arranged on the first insulating layer 101. The first insulating layer 101 It is made of flexible insulating material or anisotropic conductive material, and the shielding layer 102 is made of conductive material or magnetically conductive material.

[0038]The shielding film 1 described in this embodiment has a multilayer structure, the first insulating layer 101 is a flexible insulating material or an anisotropic conductive material, and the shielding layer 102 is a conductive material, so that the electronic components of the circuit board are shielded by the shielding film 1 , the first insulating layer 101 can be pasted on the surface of the electronic component to be shielded, because the material of ...

Embodiment 2

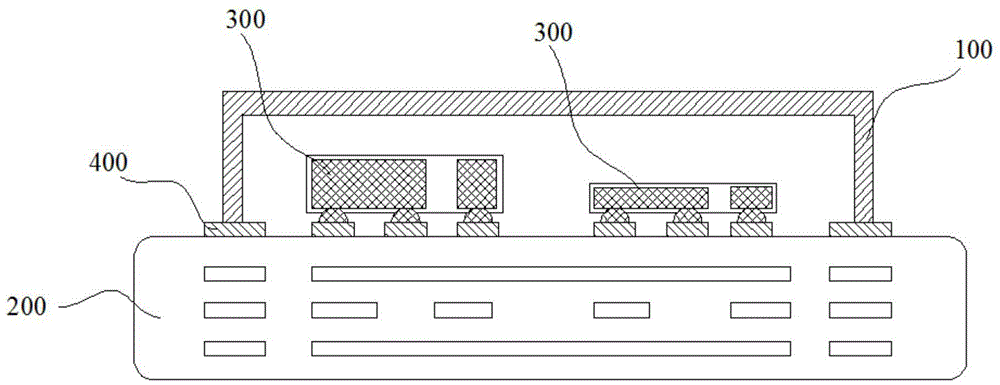

[0053] refer to Figure 5 , Figure 5 As a specific embodiment of the shielded circuit board in the embodiment of the present invention, the shielded circuit board described in this embodiment includes:

[0054] The shielding film 1, the shielding film 1 includes a first insulating layer 101 and a shielding layer 102, the shielding layer 102 is arranged on the first insulating layer 101, wherein the first insulating layer 101 is a flexible insulating material or an anisotropic conductive material, the The shielding layer 102 is a conductive or magnetically conductive material;

[0055] The circuit board 2 is provided with electronic components 3 on the circuit board 2, the shielding film 1 is covered on the electronic components 3, the first insulating layer 101 can be attached to the upper surface of the electronic components 3 of the circuit board 2, the shielding film 1 and the circuit board 2, the shielding layer 102 is connected to the grounding pad 4, and the electroni...

Embodiment 3

[0069] refer to Image 6 , Image 6 As a specific embodiment of the shielded circuit board in the embodiment of the present invention, the shielded circuit board described in this embodiment includes:

[0070] The shielding film 1, the shielding film 1 includes a first insulating layer 101 and a shielding layer 102, the shielding layer 102 is arranged on the first insulating layer 101, the first insulating layer 101 is a flexible insulating material or an anisotropic conductive material, and the shielding layer 102 is conductive or magnetically conductive material;

[0071] The circuit board 2 is provided with electronic components 3 on the circuit board 2, the shielding film 1 is covered on the electronic components 3, the first insulating layer 101 can be attached to the upper surface of the electronic components 3 of the circuit board 2, the shielding film 1 and the circuit board 2, the shielding layer 102 is connected to the grounding pad 4, and the electronic component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com