Preparation method for micron-sized spherical CZTSSe monocrystalline particles

A technology of copper-zinc-tin-sulfur-selenium and single crystal particles, which can be used in final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc. and performance optimization difficulties, unfavorable performance of CZTSSe batteries, etc., to achieve the effects of easy industrial production, low price, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

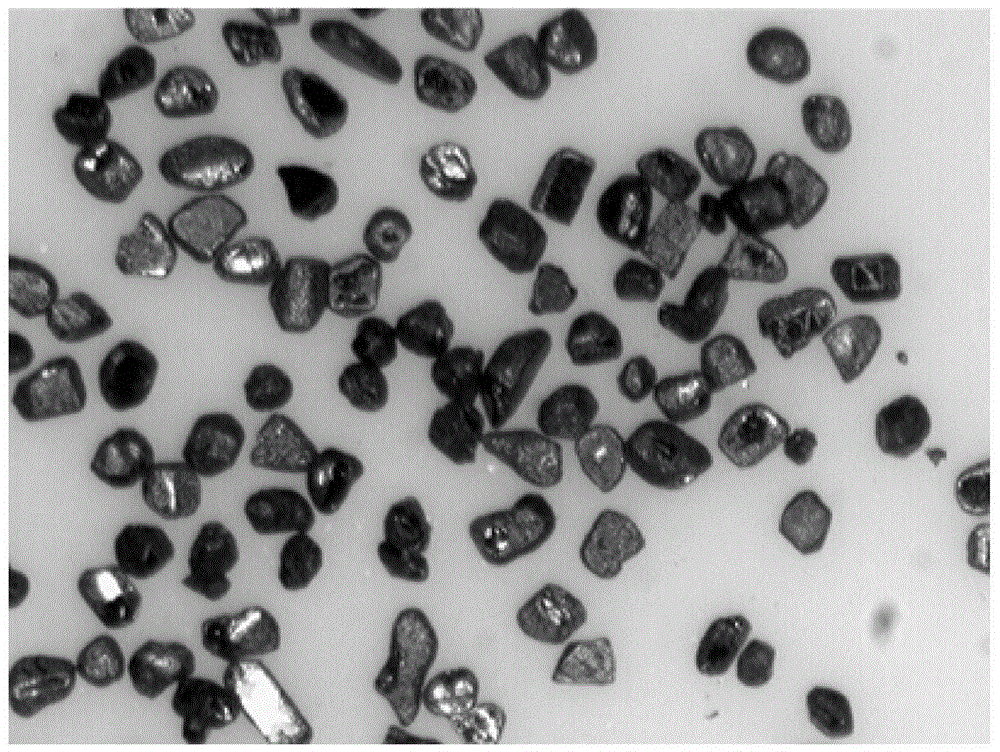

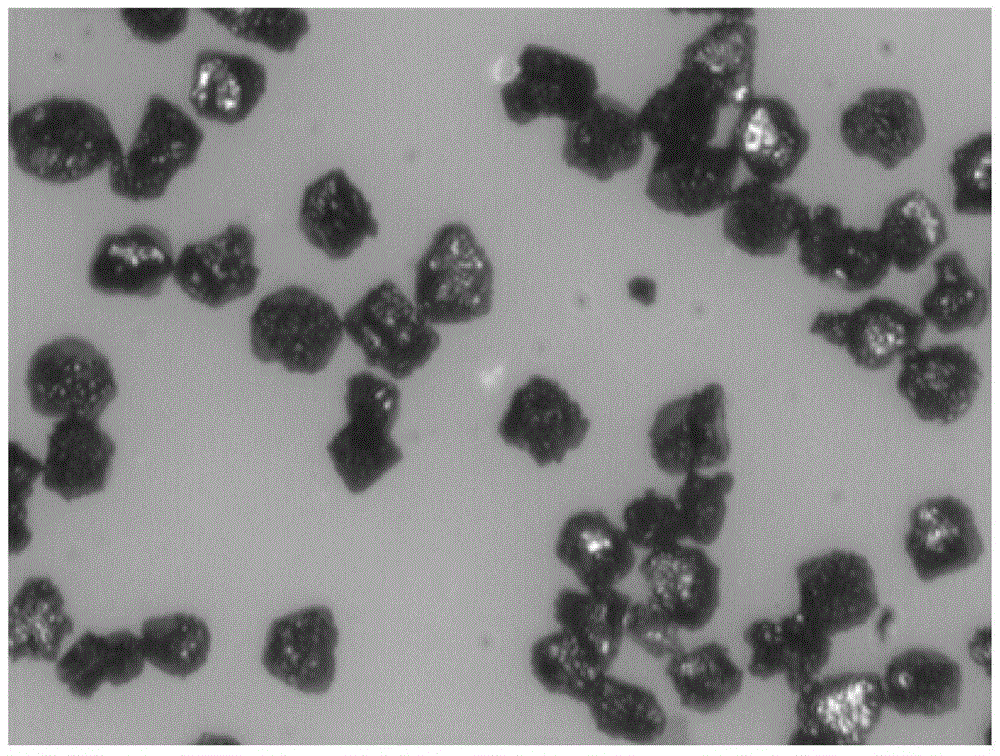

[0043] (1) Preparation of Cu by hydrothermal method 2 ZnSnS 4 Nanoparticles: add 2 mmol CuCl 2 ·2H 2 O, 1 mmol ZnCl 2 , 1 mmol SnCl 4 ·5H 2 O was dissolved in 30mL deionized water and stirred for 10min to obtain a clear solution A; 5 mmol thiourea was dissolved in 20ml deionized water and stirred for 10min to obtain a clear solution B; solution B was slowly added to solution A under stirring to obtain a white Turbid solution, stir for 10 min to obtain a mixed solution, transfer the mixed solution into a 100ml polytetrafluoroethylene autoclave and place the reaction kettle at 180℃ for 16h, cool to room temperature with deionized water and absolute ethanol at 8000r / min. Centrifugal separation at 60°C for 8 hours to obtain a black sample, namely CZTS nanoparticles.

[0044] (2) Preparation of copper zinc tin sulfur selenium single crystal particles by molten salt method: weigh 18 mmol CuS, 12 mmol ZnS, 10 mmol SnS, 10 mmol Se, 30 mmol CsCl and 20 mmol KI, and add 1 mmol step (1) ...

Embodiment 2

[0046] Weigh 18 mmol CuS, 12 mmol ZnS, 10 mmol Sn, 6 mmol S, 4 mmol Se, 50 mmol CsCl, and add 1 mmol of the CZTS nanoparticles prepared in step (1) of Example 1 and mix them thoroughly and mix them. Uniformity; the uniformly ground mixed sample is put into a quartz bottle, and the vacuum pump unit is used to vacuum through the three-way valve to reach 10-10 2 Pa (can also be protected by inert gas) to eliminate the influence of air on the molten salt reaction. Seal the quartz bottle with a hydrogen-oxygen flame; place the sealed quartz bottle with mixed samples in an ordinary heating furnace and heat it from room temperature to 800 Keep the temperature for 48 hours, then cool to about 600°C, take out the quartz bottle and quickly cool to room temperature (put it in water); take the sample out of the quartz bottle, remove the flux CsCl after repeated ultrasonic washing, and place the sample in a drying oven at 80°C After drying for 2 h, particles with crystal luster on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com