Copper mixed bonding method

A hybrid bonding and pre-bonding technology, applied in the field of bonding, can solve problems such as the difficulty in realizing the internal interconnection of wafer metal circuits, and achieve the effects of reducing wire resistance and delay, and good process foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

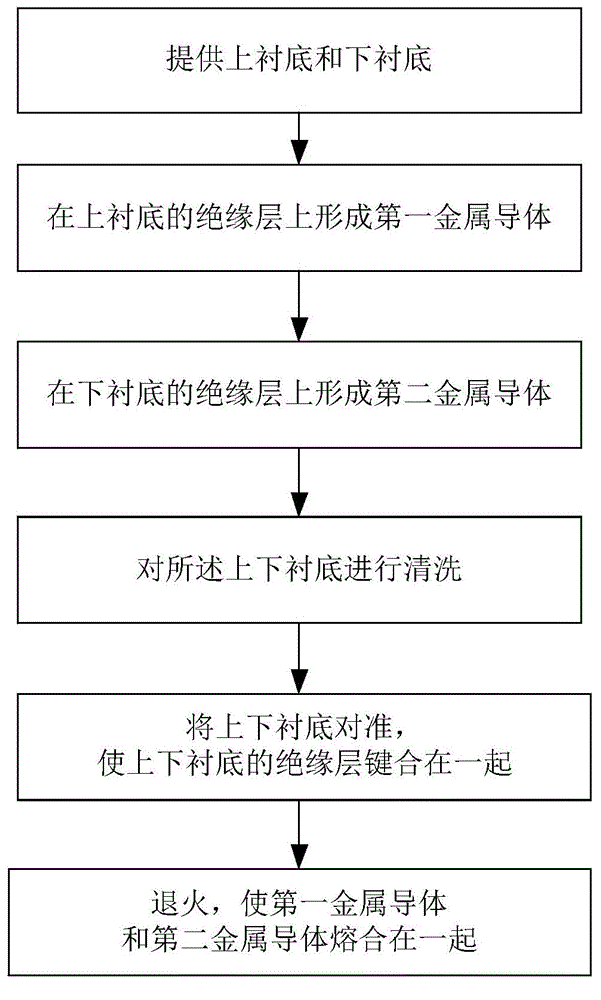

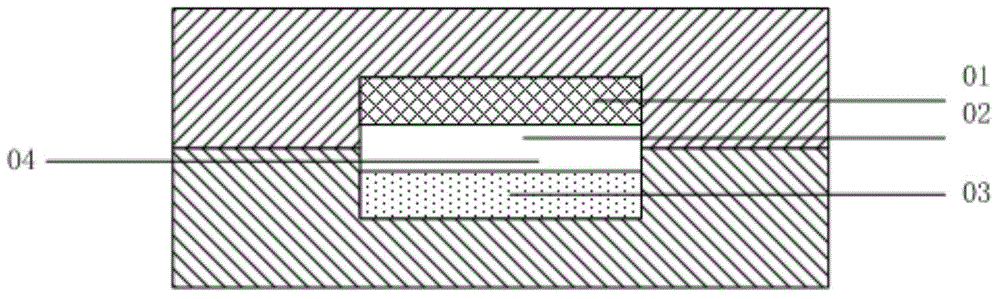

[0028] The present invention uses the traditional back-end copper interconnection technology on the surface of the wafer to be bonded to manufacture flat copper and insulators, such as a silicon dioxide insulating layer plane, and ensures one-to-one correspondence between the copper patterns on the two wafers. In the wafer hybrid bonding process, the wafer bonding is first realized, that is, the bonding between the wafer silicon dioxide insulating layer interface and the silicon dioxide insulating layer interface; secondly, the bonded wafer is placed at high temperature for annealing , due to the difference between the coefficient of thermal expansion (CTE) between the copper and the insulator, the copper with a larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com