Distributed optical fiber identification system and method for hydraulic structures and their basic seepage conditions

A technology of distributed optical fiber and hydraulic structure, which is applied in the direction of permeability/surface area analysis, testing of machine/structural components, testing of moving fluid/granular solid, etc. It can solve the problems of increasing the cost of producing optical fiber, complex coding, and voltage instability and other issues, to achieve the effect of improving engineering application capabilities, expanding the scope of application, and facilitating production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

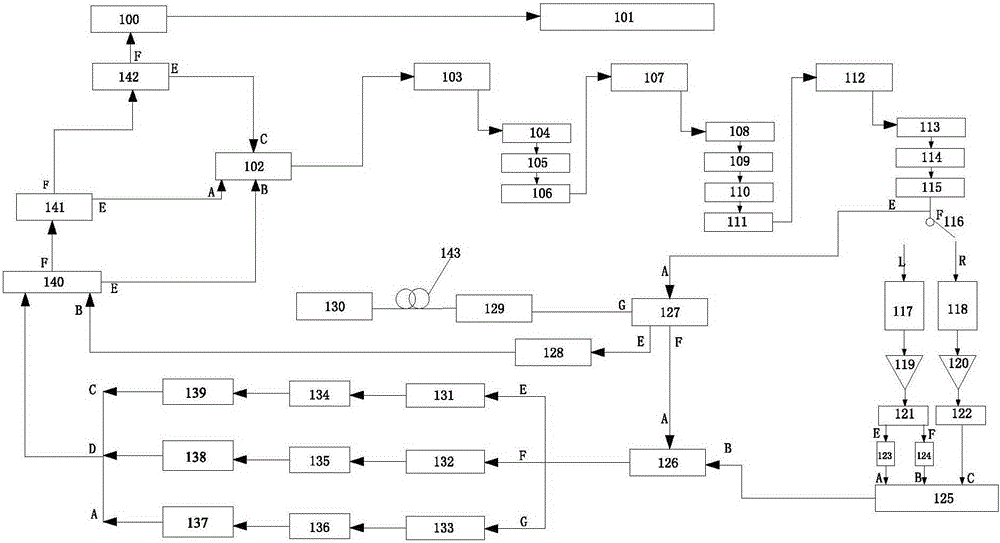

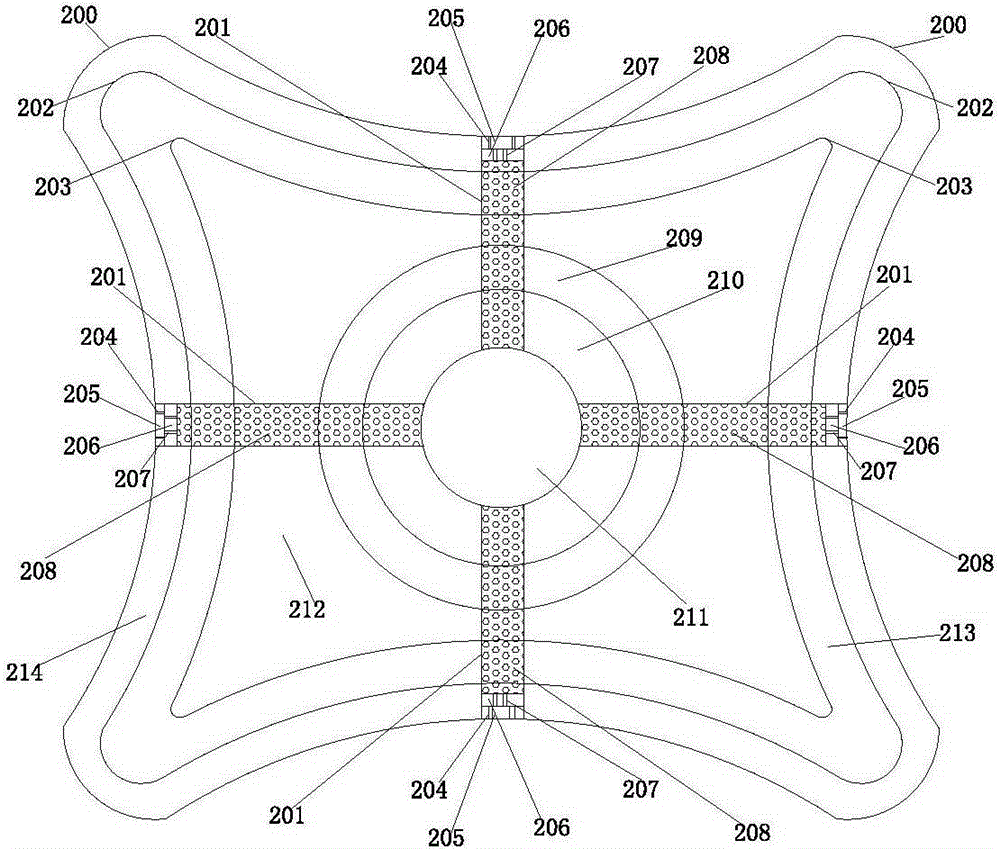

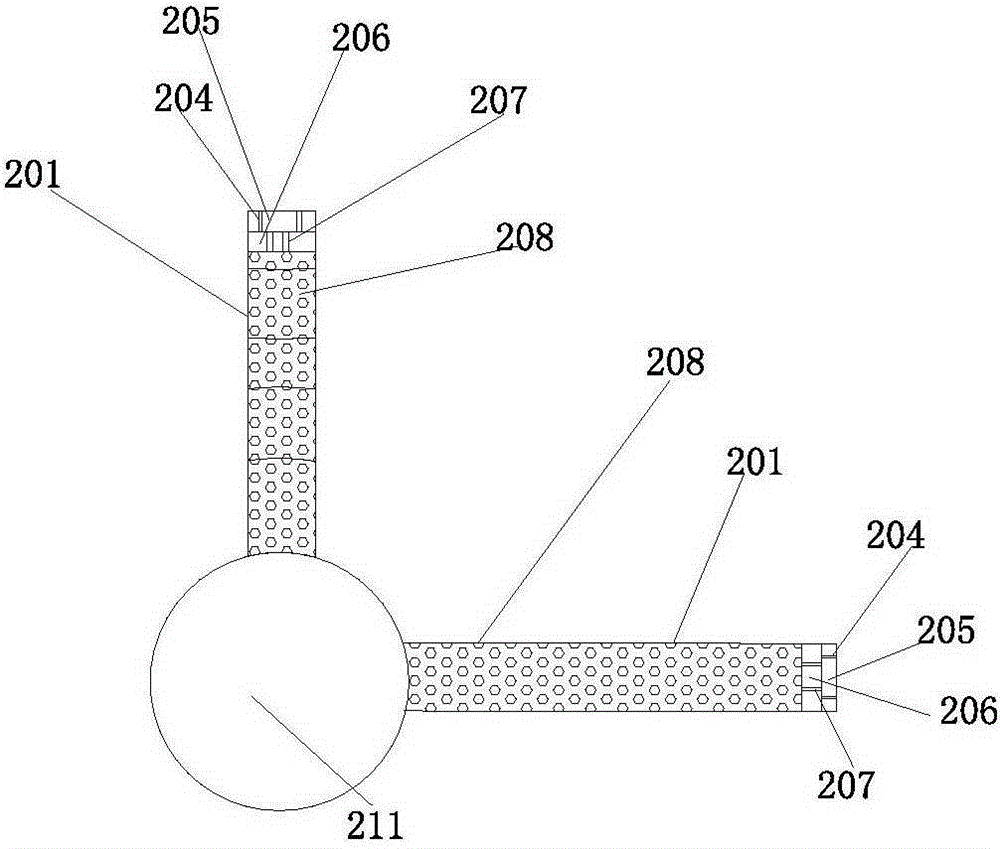

[0035] like Figure 1 to Figure 3 As shown in the figure, a distributed optical fiber identification system for a hydraulic structure and its basic seepage state of the present invention includes a special single-mode fiber 143 for self-controlled heat source seepage measurement that is vertically staggered in the seepage monitoring area 130 of the hydraulic structure, and The optical path coupler 127 and the synchronization controller 102 are connected with the special single-mode optical fiber 143 for self-controlling heat source osmotic measurement. The controller 102 communicates with the mode-locked laser 103, the first wavelength division multiplexer 104, the polarization beam splitter 105, the isolator 106, the nonlinear amplifier 107, the grating pair 108, the liquid crystal spatial light modulator 109, the diffraction grating 110, the reflection The mirror 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com