Vapor Chamber with Structure having capillary force

A technology of capillary force and vapor chamber, applied in laboratory appliances, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as small ratio of length to width of attachment area, limitation of evaporation and heat dissipation, performance degradation of vapor chamber, etc. To achieve the effect of improving heat dissipation and cooling function, increasing the contact area, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

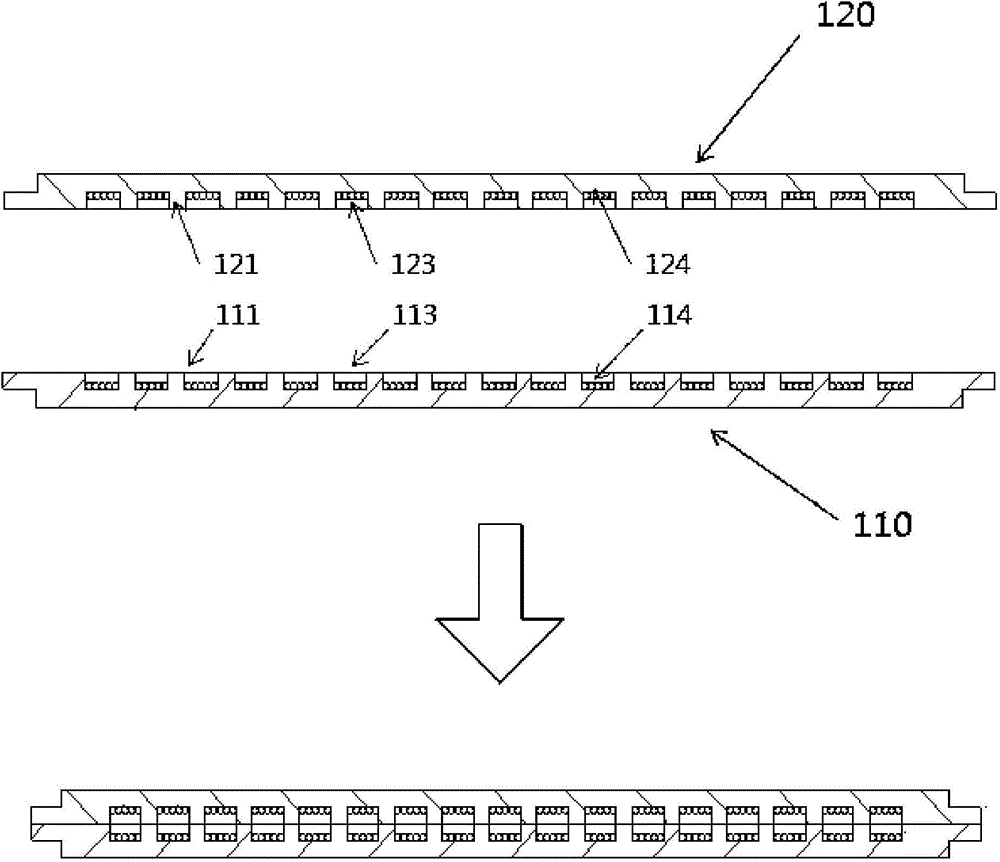

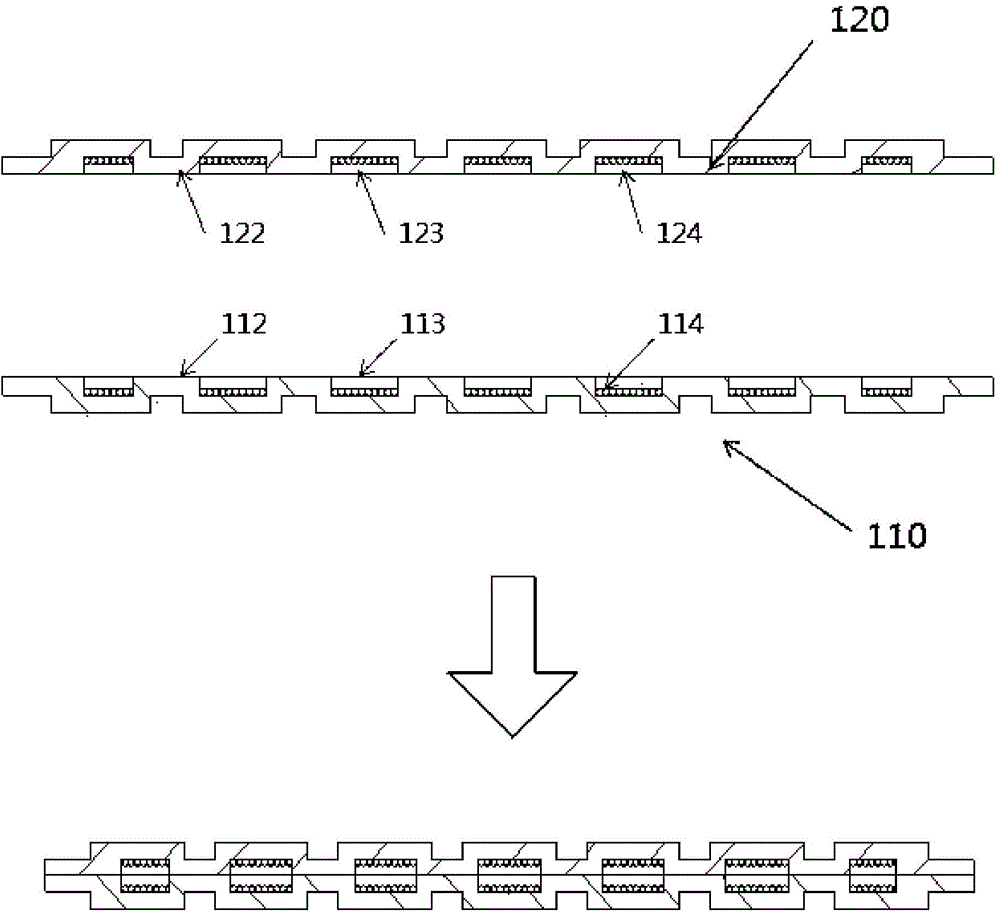

[0048]The technical features of this invention are as follows: the lower plate and the upper plate form a soaking plate, and grooves or grooves are formed on the lower plate and the upper plate. On the channels formed between grooves or grooves, a porous substance is formed due to the accumulation of layers of metal powder. After being chemically filtered and then solidified, the layers of metal powder are stacked to form a porous structure. These porous structures make the capillary force develop rapidly, and the cooling performance of the capillary force is also significantly improved, and portable electronic products can dissipate heat more effectively.

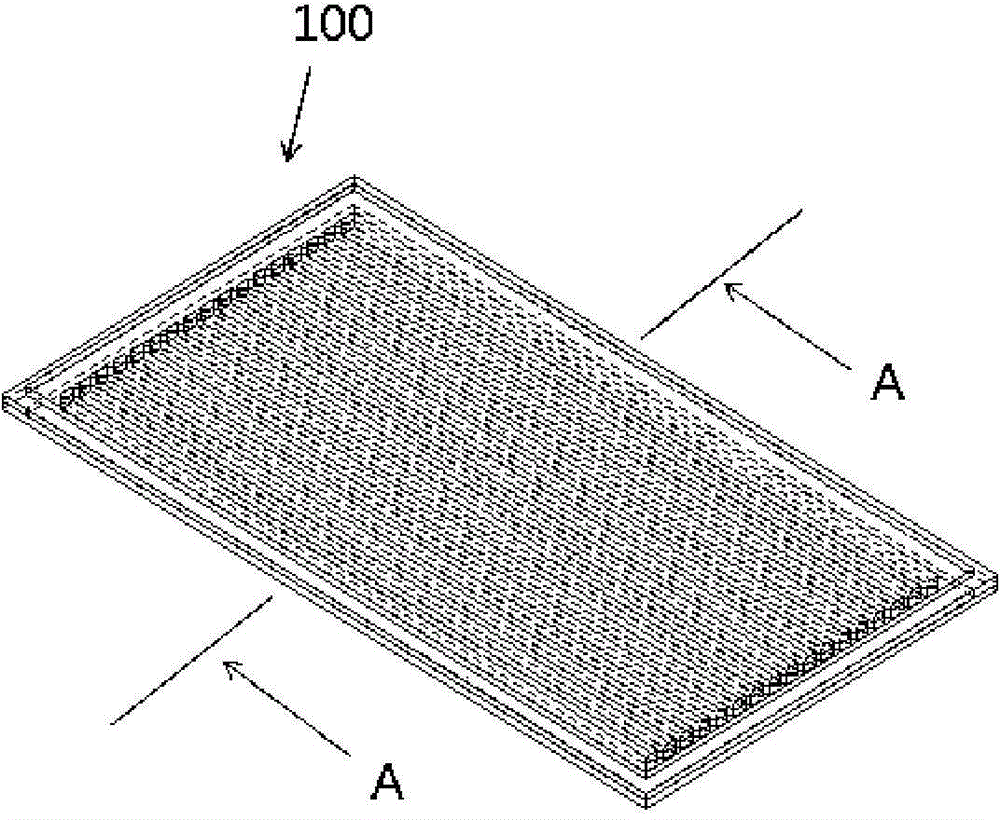

[0049] refer to figure 1 and figure 2 , the embodiment of the present invention provides a vapor chamber formed by a structure with capillary force, which is composed of a lower plate 110 and an upper plate 120, and liquid oil is injected between the upper and lower plates to achieve a vacuum-tight state, thereby mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com