Cast pumping well sleeve installing method

An installation method and casing technology, which is applied in industrial construction and other fields, can solve the problems of large rework opportunities, increased project cost, and long construction period, and achieve the effects of saving construction period, increasing chances of success, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

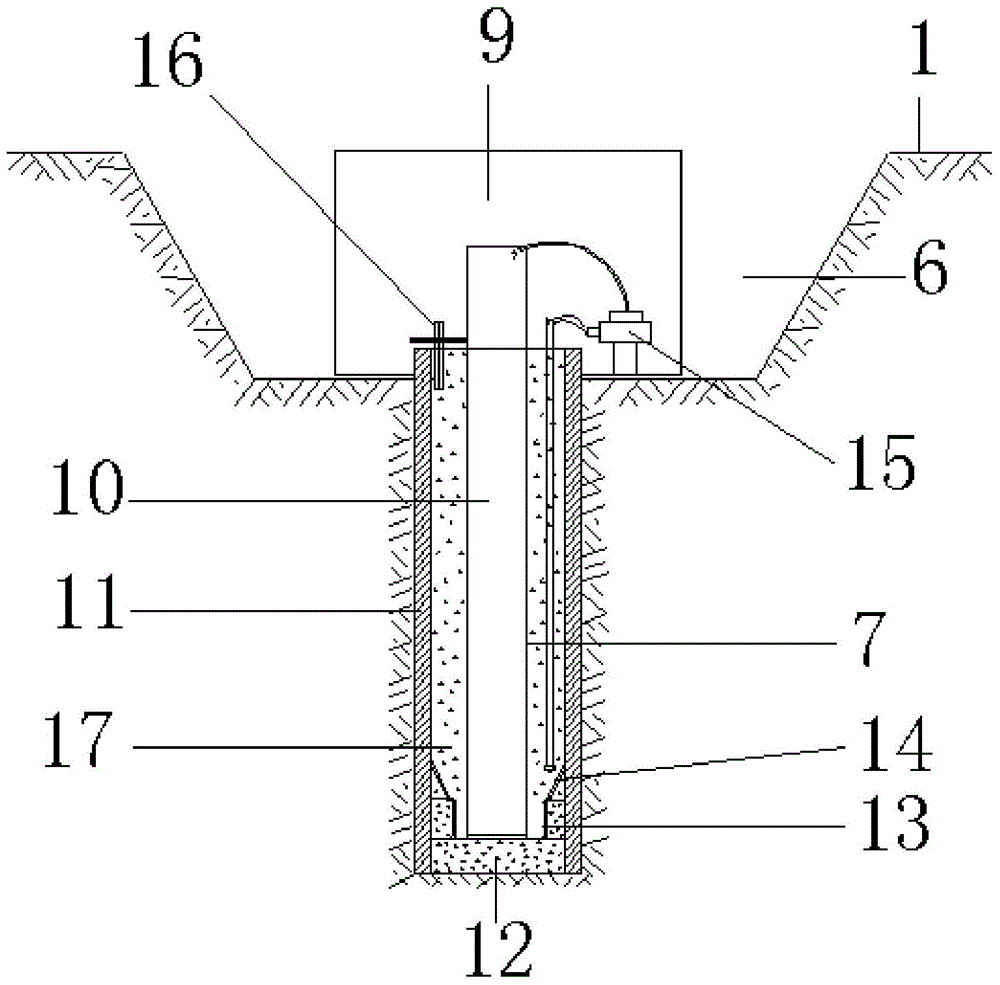

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , figure 2 The casting casing installation method shown in the well comprises the following steps:

[0021] A. Carry out earthwork excavation on the field level ground 1 to form the foundation pit 6 of the earthwork excavation of the casting machine well, and the excavation depth reaches the design elevation position at the bottom of the casting machine well 9 to form the construction foundation pit of the casting machine well 9;

[0022] B. In the foundation pit 6 excavated by the earthwork of the casting machine shaft, manually excavate pile holes and casing installation tunnels 10 downwards. When excavating the tunnels, manually dig pile hole bricks or steel casing wall 11, and the depth of the tunnels is lower than that designed at the bottom of the casing. Over-excavate at a certain depth of about 300mm at an elevation and carry out tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com