Multi-layer roller hearth waste heat utilization cyclic furnace and waste heat recovery method thereof

A waste heat, roller bottom technology, applied in heat treatment furnaces, furnaces, waste heat treatment and other directions, can solve the problems of high electricity price and high production cost of periodic furnaces, achieve high production efficiency, avoid hidden troubles and unsafe use, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

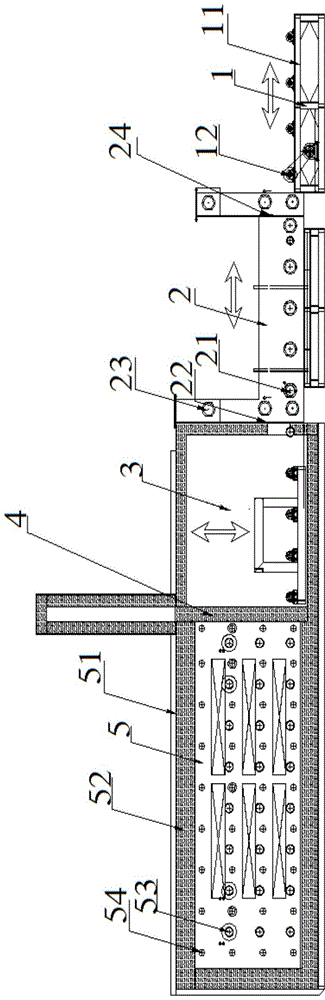

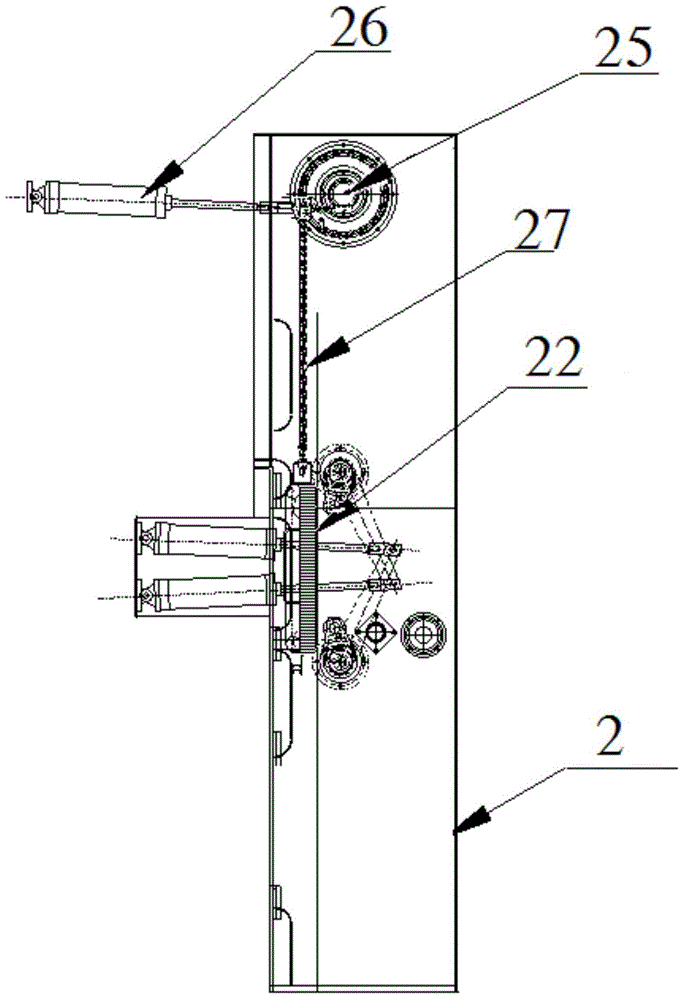

[0035] Embodiment 1: as Figures 1 to 2 As shown, the multi-layer roller bottom waste heat utilization periodic furnace described in Example 1 includes a furnace body 5, a lifter 3, a vacuum ventilation chamber 2, a feeding and discharging table 1, a transmission system, and a control system. The transmission system It includes a transmission device, the transmission device is connected with the motor, the feeding and discharging table 1, the vacuum ventilation chamber 2, the elevator 3 and the furnace body 5 are connected in sequence, and an electric motor is installed between the furnace body 5 and the elevator 3 A furnace door 4, a furnace shell 51 is provided outside the furnace body 5, a refractory insulation layer 52 is provided around the hearth of the furnace body 5, and a plurality of heating bodies 54 and at least two layers of furnace inner rollers 53 are provided in the inner furnace of the furnace body 5. , the supporting rollers 53 in each layer of the furnace ar...

Embodiment 2

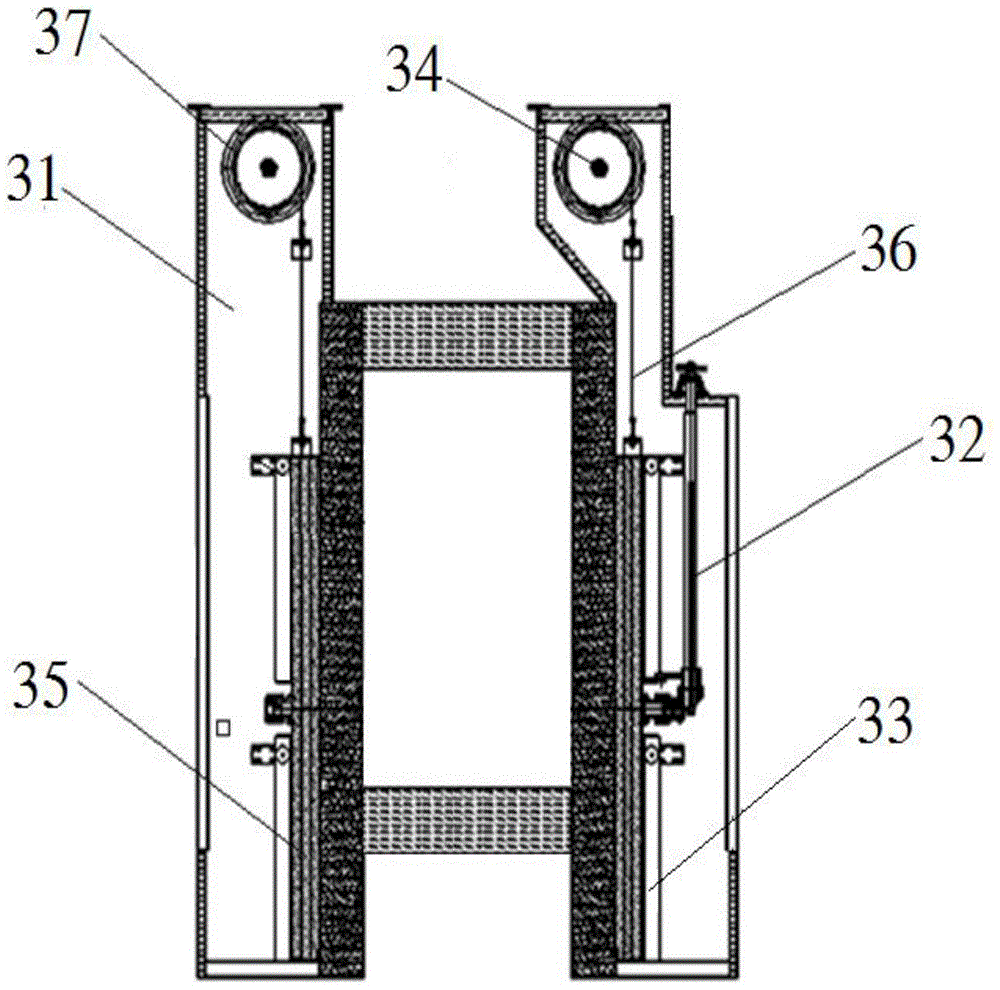

[0036] Embodiment 2: As a preferred embodiment, the difference between the multi-layer roller bottom waste heat utilization cycle furnace described in Embodiment 2 and Embodiment 1 is that the elevator 3 is provided with a shell, and the lifting area in the elevator 3 is The top and bottom are provided with thermal insulation layers.

[0037] In the multi-layer roller bottom waste heat utilization cycle furnace described in Embodiment 1 and Embodiment 2, the metal workpiece passes through the feeding and discharging idler roller 12 on the feeding and discharging table 1, the air chamber idler roller 21 in the vacuum ventilation chamber 2, The driving rollers on the lifting rack are driven by the transmission device to be transmitted to the inner rollers 53 of each layer of furnace in the furnace body 5 . Wherein, since at least two layers of furnace rollers 53 are arranged in the body of furnace 5, and a lifter 3 is provided on one side of the body of furnace 5, metal workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com