A method for laying cables in a hull bridge

A technology of cable laying and cab, which is applied in the field of cable laying in the hull cab, can solve the problems of cab equipment control or signal failure, increased structure, difficult construction, and unfavorable maintenance, etc., to achieve good fire performance, low cost, and easy construction The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

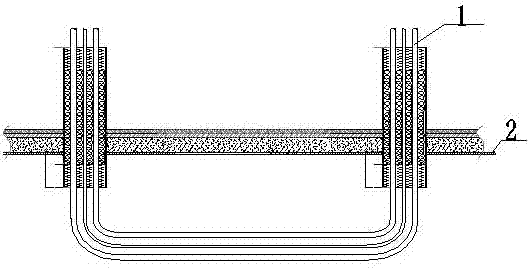

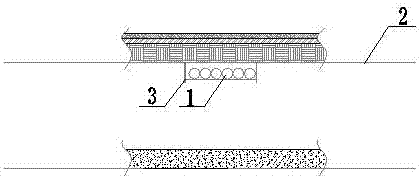

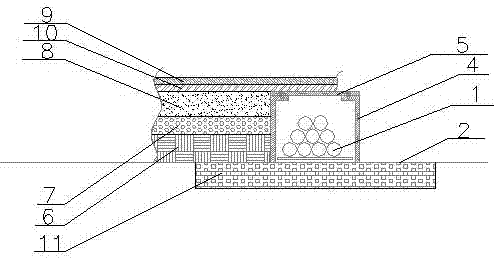

[0019] Such as figure 1 As shown, the present invention discloses a method for laying a cable 1 in a hull cab. The method is that the cable 1 is installed on the front of the cab deck 2 through the cable trough 4, and a fireproof layer is laid on the back of the cab deck 2 in the area where the cable trough 4 is located. .

[0020] The specific steps of the above method are as follows:

[0021] The first step is to lay cables: first install the cable groove 4 on the cab deck 2, then install the cable 1 in the cable groove 4, and when the cable 1 is installed, install the cable groove cover 5 at the notch of the cable groove 4;

[0022] The second step is to lay high-level layers: on the cab deck 2 around the cable trough 4, a sound-insulating rock wool layer 6, a lightweight deck covering layer 7 and a deck covering layer 8 are successively laid, and the lightweight deck covering layer adopts expanded perlite. The upper end surface of the deck coating layer 8 is flush with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com