Battery cover plate assembly, preparation method thereof, single battery and battery pack

A battery cover and component technology, which is applied in the direction of battery cover/end cover, secondary battery manufacturing, battery pack components, etc., can solve the problem of insufficient connection between electrodes and cover plates, affecting battery output, safety performance, and insufficient sealing performance Ideal and other issues, to achieve the effect of reducing moving bumps, increasing connection firmness, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method for the above-mentioned battery cover plate assembly, including: setting a sealing layer on the surface of the electrode terminal and first performing surface treatment on the surface of the electrode terminal where the sealing layer needs to be set so that it has a microporous structure; setting the hollow rivet On the cover plate, the hollow part of the hollow rivet communicates with the through hole; pass the electrode terminal provided with the sealing layer through the hollow part of the hollow rivet and ensure that the sealing layer on the electrode terminal is at least partly in the hollow rivet; between the sealing layer and the hollow Injection molded insulation between rivets. The high temperature of injection molding makes the sealing layer and insulating parts in a molten state, and the viscous fluid state insulating material is fused with the surface of the molten sealing layer in contact with it under...

Embodiment 1

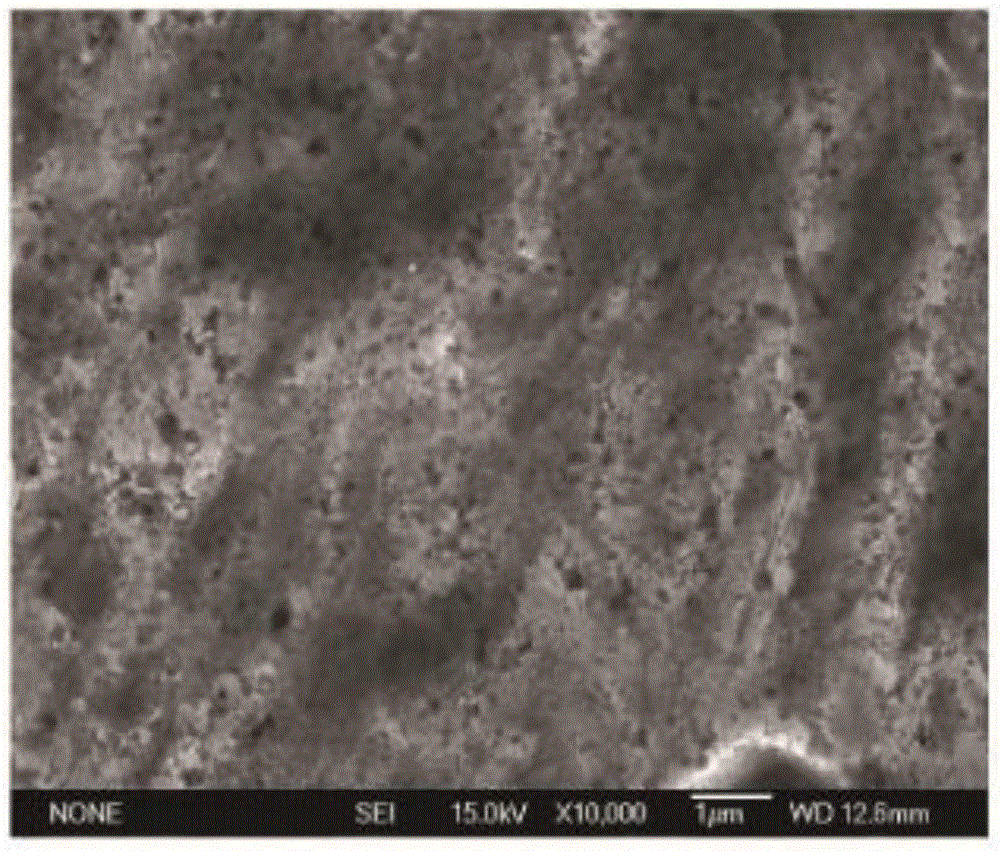

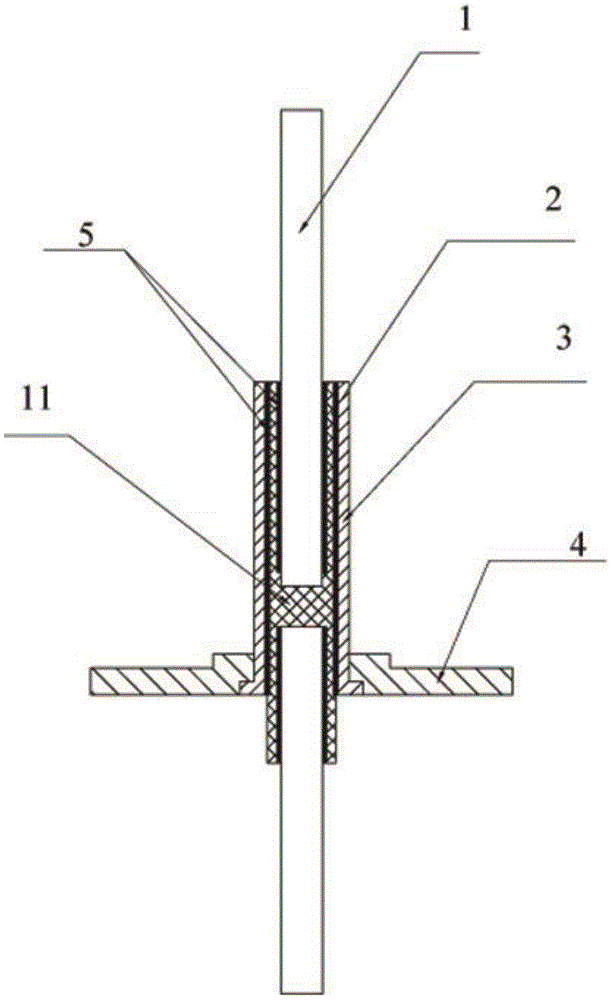

[0041] Such as figure 1 , 2 , 4, the cover assembly includes an electrode terminal 1, an insulator 2, a hollow rivet 3, a cover 4 and a sealing layer 5, and the cover 4 is provided with a through hole. The inner surface of the hollow rivet 3 is etched with concentrated hydrochloric acid for 20 minutes to form a microporous structure with a micropore diameter distribution of 10nm-1μm and an average micropore depth of 50nm-2μm. The inner surface is coated with the NMP (N-methylpyrrolidone) solution of oligomer coated polymer material PPS (polyphenylene sulfide). After drying, it is heated at 340 degrees until the coated polymer material is melted. Sinter for 30 minutes until a dense sealing layer 5 is formed. After connecting the hollow part of the hollow rivet 3 with the sealing layer 5 on the inner surface to the through hole on the cover plate 4, it is welded with the cover plate 4 to form an integral structure. The aluminum electrode terminal 1 is etched with concentrated...

Embodiment 2

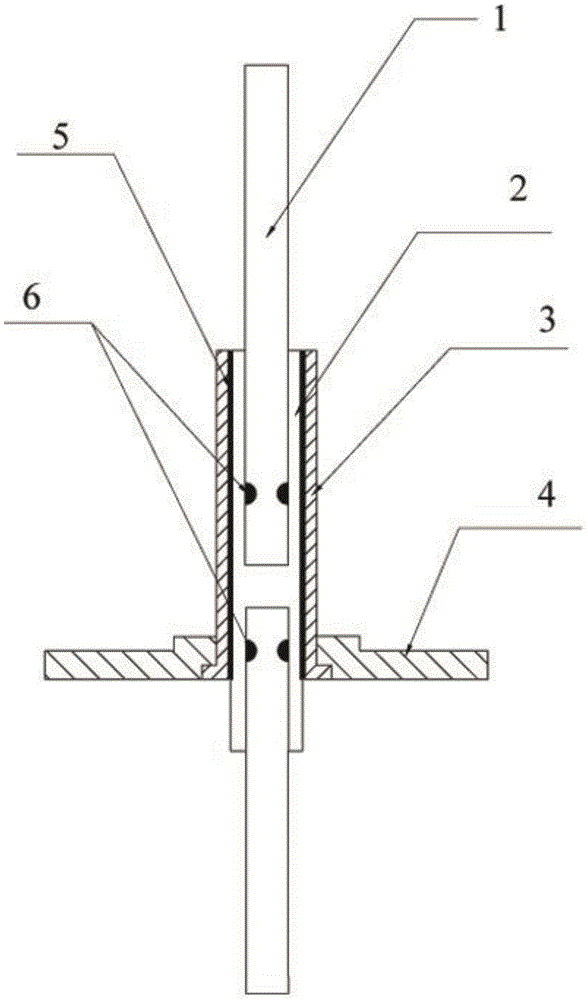

[0043] Such as figure 1 , 3 , 4, the cover assembly includes an electrode terminal 1, an insulator 2, a hollow rivet 3, a cover 4 and a sealing layer 5, and the cover 4 is provided with a through hole. The inner surface of the hollow rivet 3 is etched by concentrated hydrochloric acid and alkali for 20 minutes to form a microporous structure with a micropore diameter distribution of 50nm-2μm and a micropore depth of 200nm-2μm. The inner surface of the hollow rivet 3 is coated with The prepared oligomer is coated with an aqueous solution of polymer material PPS, dried, heated to 320° C. to melt the polymer material, and sintered for 30 minutes to form a dense sealing layer 5 . Carve two circles of concave sealing grooves 6 on the surface of the part of the aluminum electrode terminal 1 that needs to be sealed and connected with the cover plate 4, and etch with concentrated hydrochloric acid and alkali for 15 minutes to form a micropore size distribution of 50nm-2μm on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com