A bonding head device

A bonding head and spline shaft technology, which is applied in the field of semiconductor packaging, can solve the problem of large Z-direction size of the bonding head device, achieve the effects of reducing the Z-direction size and installation space, improving precision, and ensuring linear motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

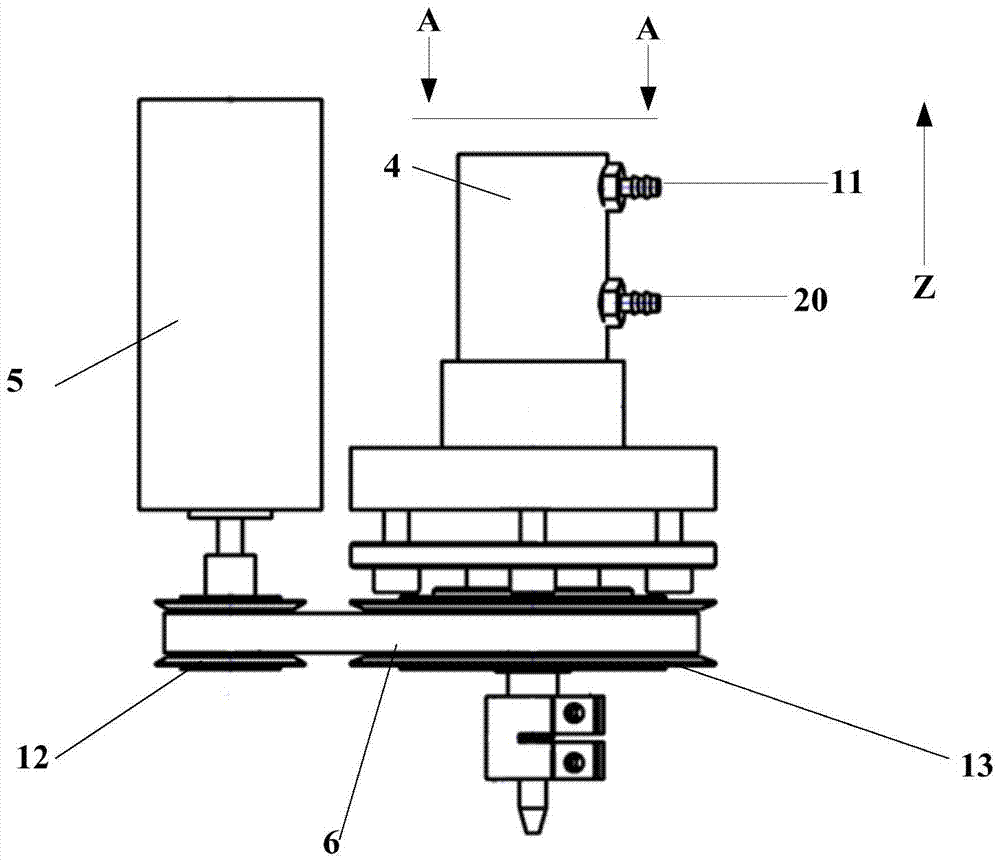

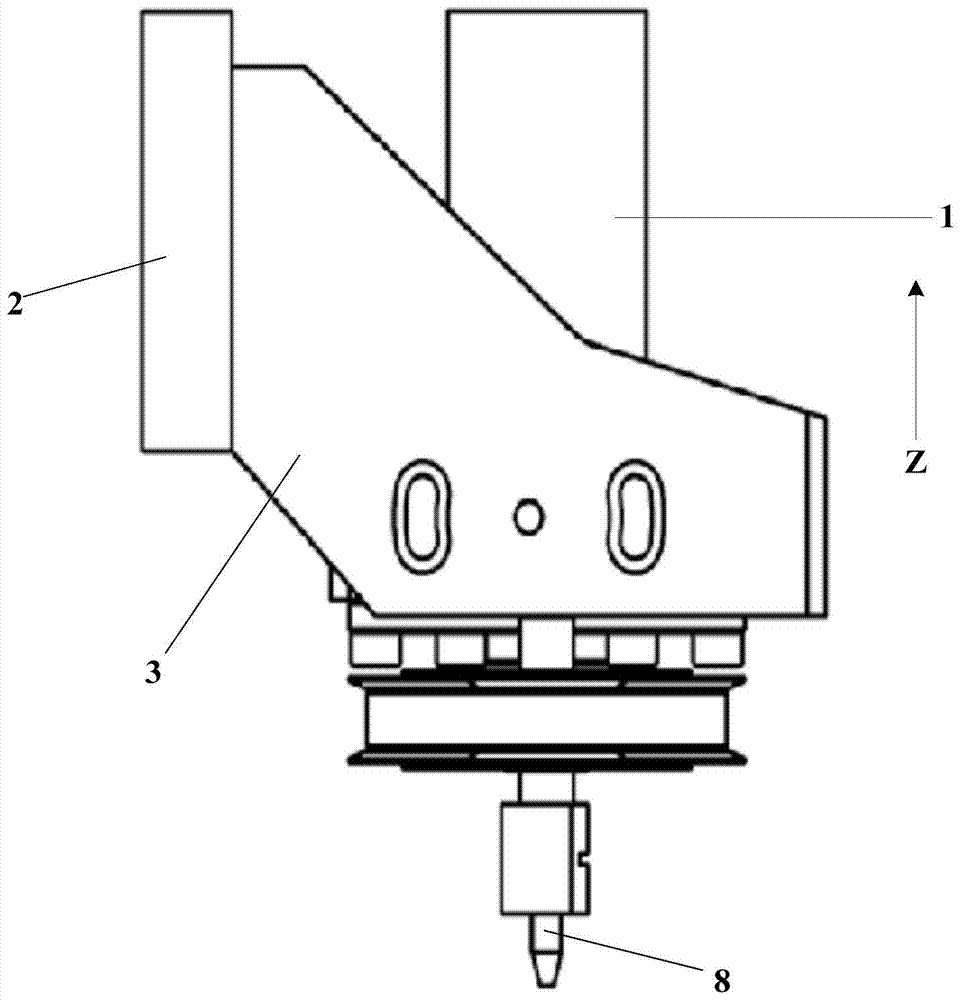

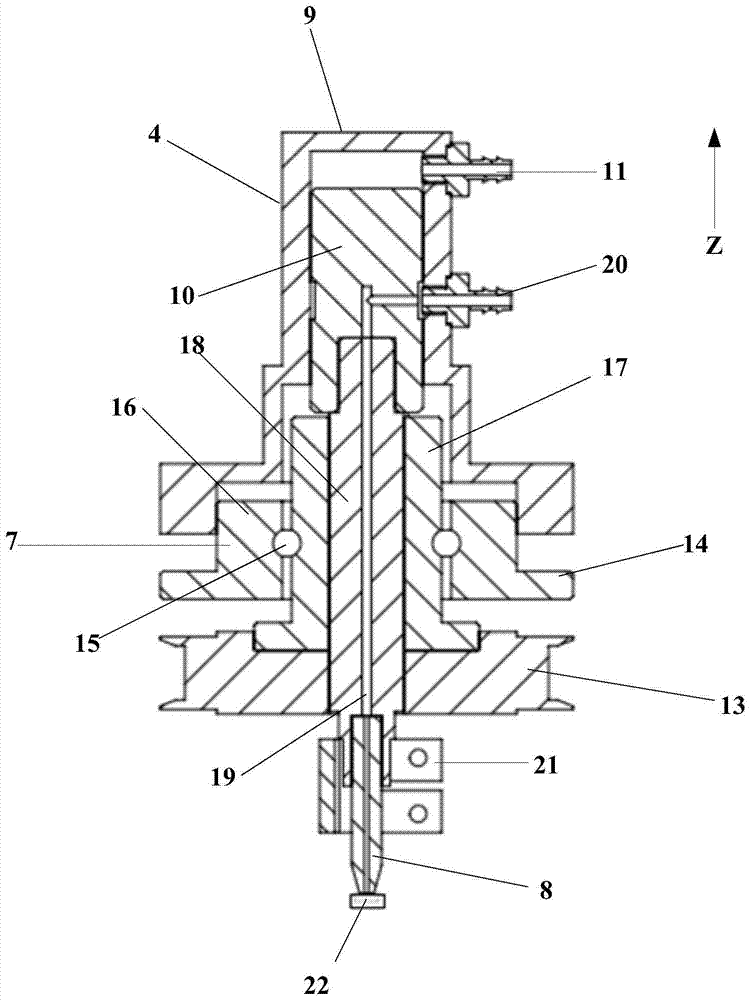

[0028] see Figure 1 to Figure 3 , the present invention provides a bonding head device for the existing problems, the device includes: a device body 1, a linear slider 2 for connecting with the external drive, a connecting device body 1, a linear slider 2 Fix the bracket 3; further, the linear slider 2 is connected with the external linear motor drive or the lead screw drive, and then drives the bonding head device to perform linear motion; preferably, three sets of linear drives can be used to set X, Y, and Z respectively. The three-direction linear guide rail realizes the movement of the bonding head device in three directions, and position sensors and grating scales can be installed on the linear guide rail to improve the position accuracy of the bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com