Handle assembly of regulating valve

A technology for regulating valves and handles, which is applied in the direction of valve operation/release devices, valve details, valve devices, etc. It can solve the problems of high cost, influence on force application effect, and insufficient appearance, etc., and achieve unique design and save size and space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

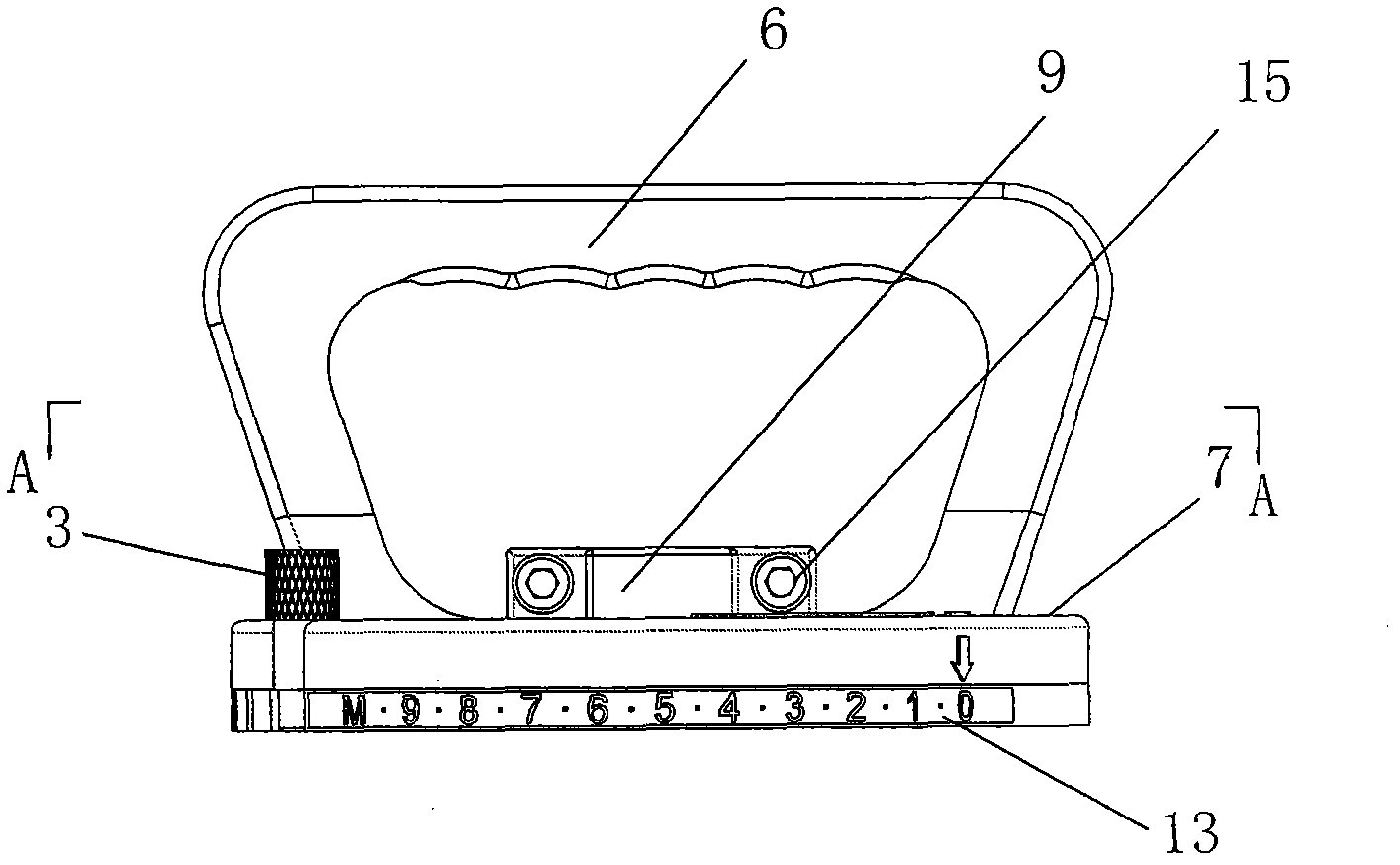

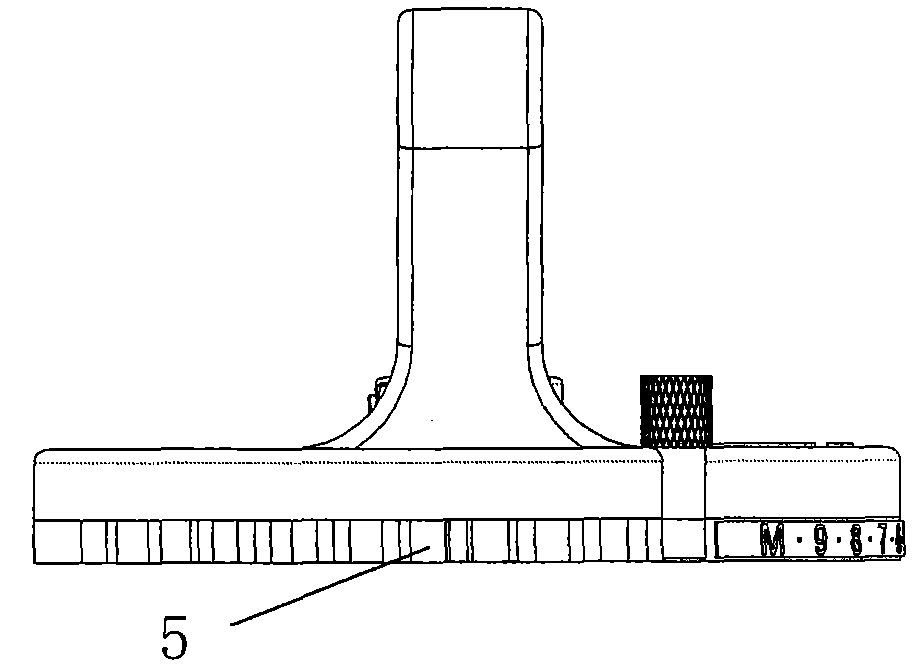

[0036] Such as Figure 1-10 The shown handle assembly of the regulating valve of the present invention includes a disk-shaped handle seat 1 fixedly connected with the regulating valve at the bottom of the handle assembly, a handle body 2 and a locking pin 3 on the handle seat.

[0037] Wherein, the center of the handle seat 1 is a large through hole 4 that can pass through the valve shaft (not shown in the figure) of the regulating valve; within the 90° arc range of the side wall of the handle seat, a plurality of direction handles are evenly arranged in the circumferential direction. The recessed trapezoidal hole 5 through the handle seat up and down.

[0038] The handle body includes a grip portion 6 and a base plate 7, the bottom of the grip portion is fixedly connected to the base plate, and a cavity is formed between the grip portion and the base plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com