Large-area or large-volume concrete pre-buried blast hole arrangement method and blasting demolition method

A large-volume concrete, large-area technology, applied in blasting and other directions, can solve problems such as high cost and difficulty in drilling, and achieve the effects of reducing engineering costs, avoiding drilling operations, and facilitating blasting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: The concrete (with reinforcement) shear wall is 30m high, 15m long and 0.30m thick. Steel pipes with a diameter of 32 mm and a length of 15 m with notches on the outer wall are pre-buried on the center line of the horizontal section of the shear wall at every 1 m elevation and along the contour line along the length of the wall, and the uppermost pipe is 1 m away from the upper surface , the bottom one is flush with the ground, a total of 30 steel pipes. Both ends of each steel pipe are opened on the side of the concrete wall.

[0057] Utilize above-mentioned pre-embedded steel pipe to remove blasting hole as shear wall, construction procedure of the present invention is:

[0058] 1) Find the openings at both ends of the pre-buried blast hole, and clean the pipe with compressed air;

[0059] 2) Insert the rope from one end opening of the pre-buried blasthole to the other opening; then tie the discontinuous emulsified charge and detonating cord w...

Embodiment 2

[0061] Embodiment 2: The concrete dam has a top thickness of 6m, a bottom thickness of 50m, a height of 80m, and a length of 200m. Such as Figure 10 , Figure 11 As shown in the layout of the embedded blast hole (in this example, the number of embedded pipes forming a single channel is different from that in the schematic diagram), starting from the ground of the dam foundation, the cast iron pipes with notches on the outer wall are embedded every 1.2m (also used as concrete Cooling water pipe during construction), as a pre-buried blasthole, the inner diameter of the cast iron pipe is 40mm, the pipes are all in the horizontal plane, and the direction is perpendicular to the length of the dam. In the same horizontal plane, the pipes are parallel to each other, and the distance between the pipes is 1.8m. Six pre-embedded pipes on the same plane are connected to form a single passage, and the two ends of the passage are opened on the back water surface of the dam (the length o...

Embodiment 3

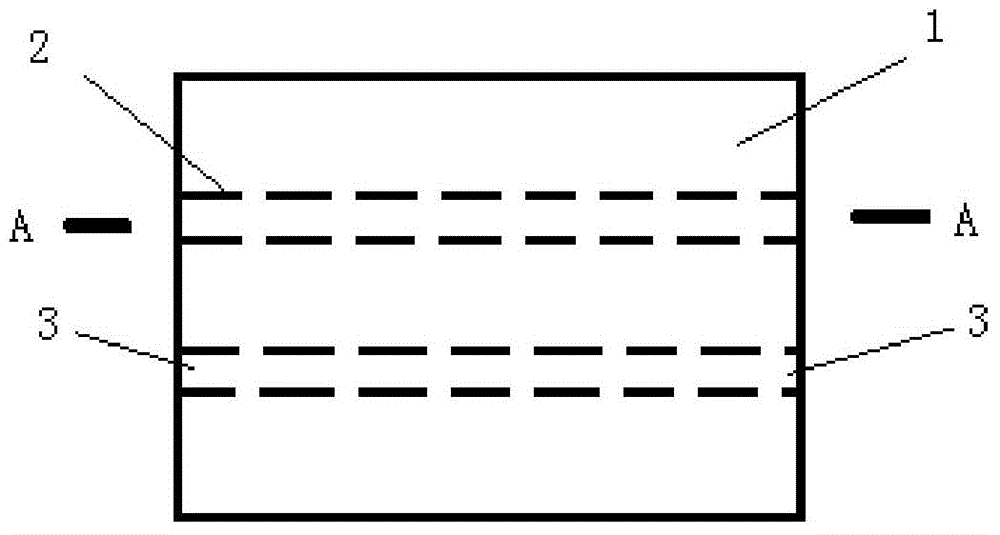

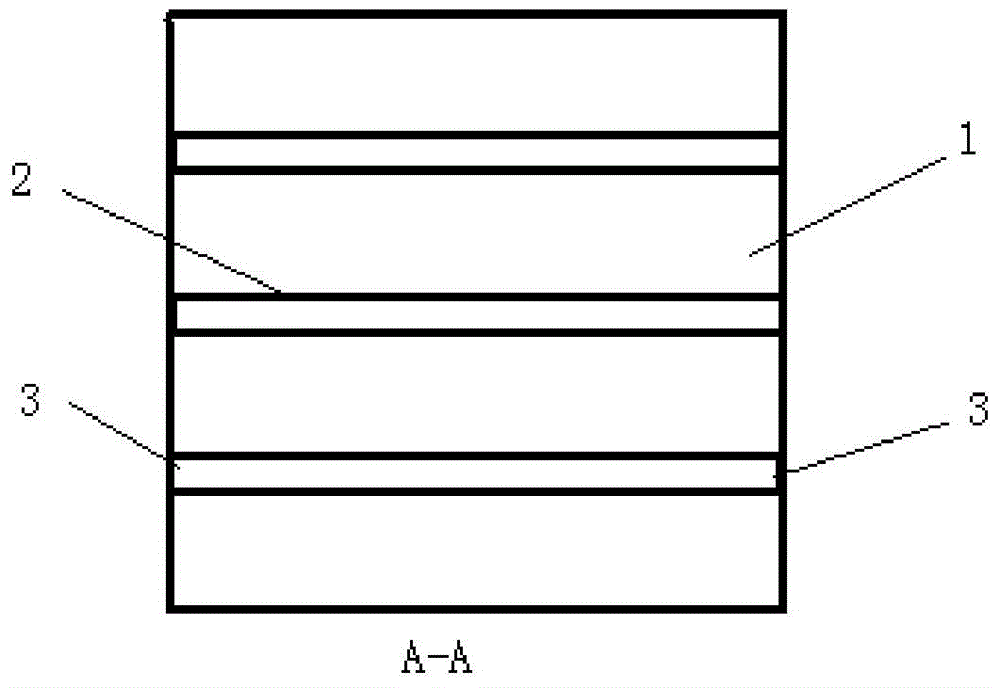

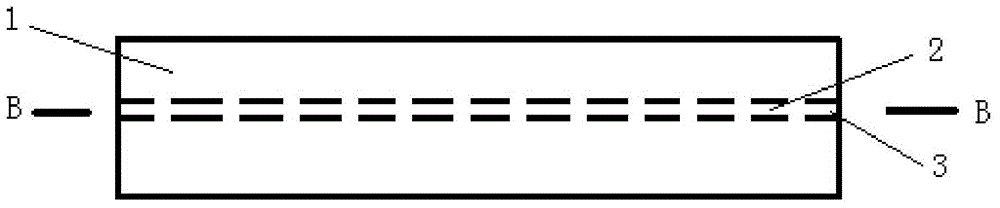

[0067] Embodiment 3: the cuboid concrete (there is steel bar inside) foundation top height 4.9m, width 6m, length 50m. Such as Figure 12 , Figure 13 As shown, starting from the foundation ground, a layer of high thermal conductivity HDPE plastic pipes (also used as cooling water pipes during concrete construction) is embedded every 0.7m as the embedded blast hole. The inner diameter of the plastic pipe is 32mm, and the pipes of the same layer are all on the same level Inside, the direction is perpendicular to the length direction of the foundation, and the distance between the pipes is 1m. In the vertical plane perpendicular to the length direction of the foundation, 6 parallel embedded pipes (one for each floor) are connected to form a single passage, and the two ends of the passage are opened on the facade of the foundation, and the length of a single passage is about 40m; except The ends of other pre-embedded pipes other than the two ends of the passage extend until t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com