Intelligent air-distribution device for solid fuel combustion

A technology of solid fuel and air distribution device, which is applied in the combustion method, combustion control, air supply adjustment and other directions, can solve the problems of insufficient combustion of fuel, inability to achieve uniform air distribution, uneven air distribution, etc., and achieve complete fuel combustion. The effect of sufficient, uniform and reasonable air distribution, and concise air distribution process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

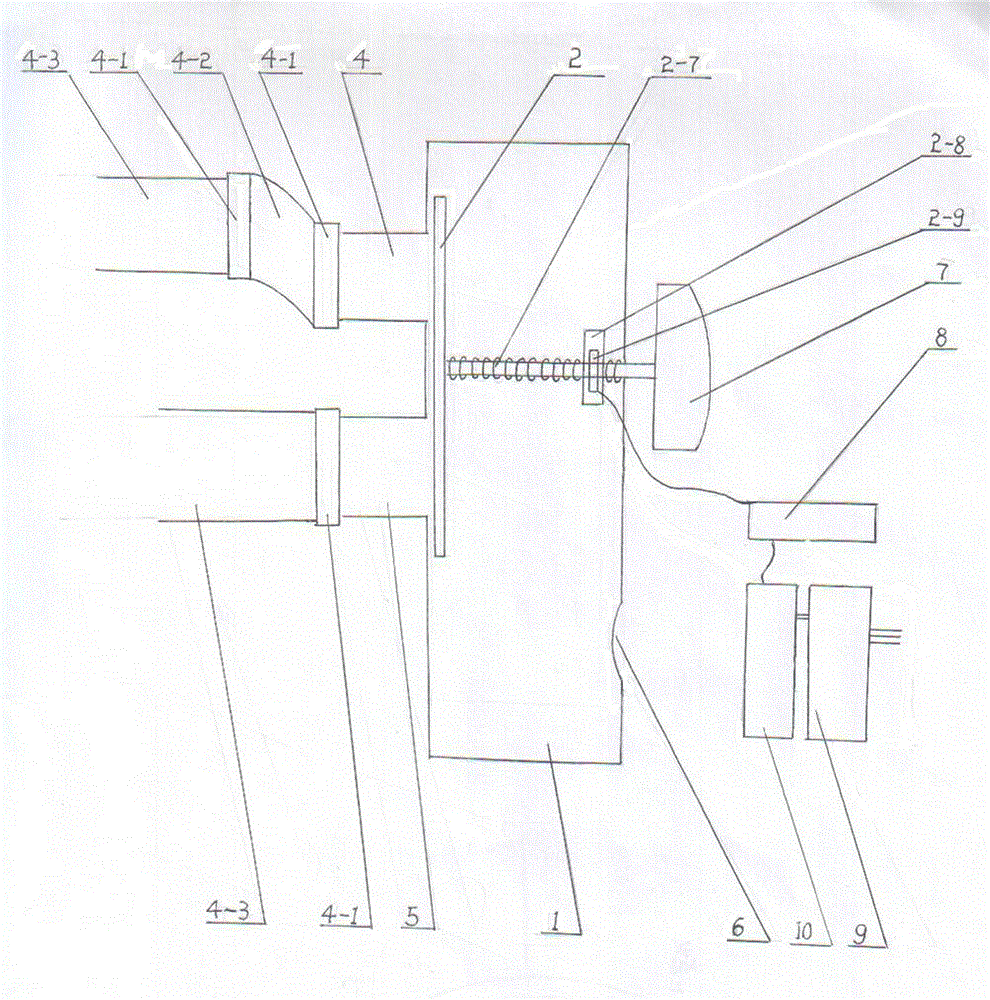

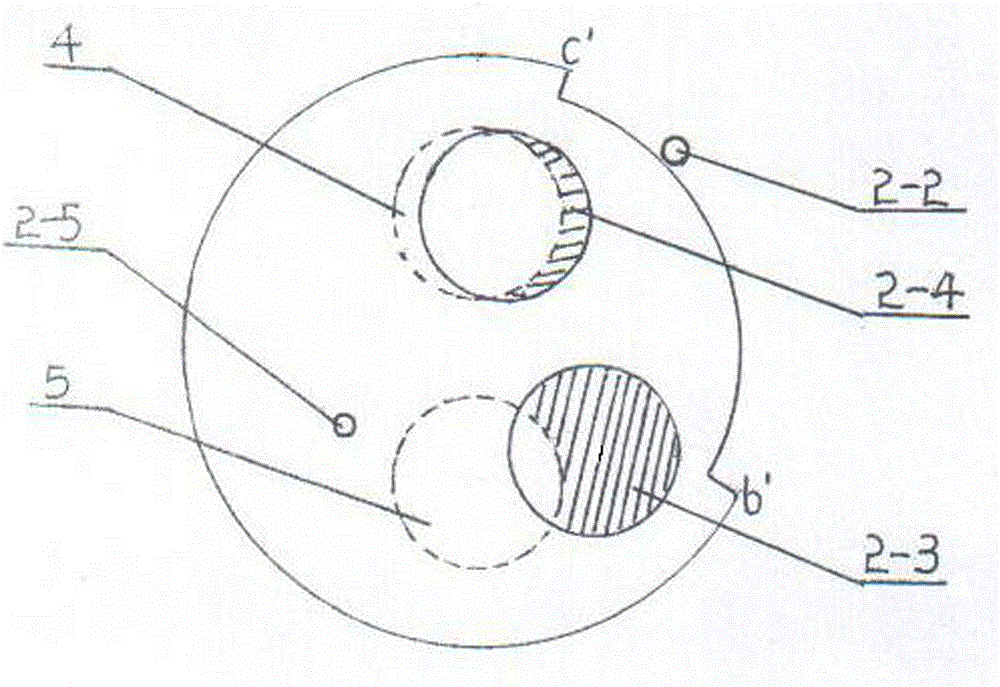

[0022] An intelligent air distribution device for solid fuel combustion, comprising an air distribution chamber 1, an air distribution baffle 2, a rotating shaft 2-6, an outer cover of the air distribution chamber 3, secondary and tertiary air inlet holes 2-4, primary air inlet Hole 2-3, air inlet 6, rotary knob 7, drive motor 8, smoke detector 9, microcomputer 10;

[0023] Among them: the air distribution cavity 1 is equipped with a movable air distribution baffle 2 and a fixed limit device 2-2, the air distribution baffle 2 is a circular plate with an empty slot 2-1, and the fixed limit device 2-2 is placed in the empty slot 2-1, and the rotating shaft 2-6 is the rotating shaft of the air distribution baffle 2. When the air distribution baffle 2 is rotated, it is constrained by the limiting device 2-2, and there are 2 air distribution baffles Can move within the range allowed by the empty slot 2-1;

[0024] The air distribution baffle plate 2 is provided with secondary and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com