Diversion tunnel plug head exhaust structure and exhaust method thereof

An exhaust method and technology of diversion tunnels, applied in water conservancy projects, hydroelectric power stations, hydroelectric power generation, etc., can solve the problems of difficult control of the exhaust process, poor construction operability, unfavorable structural safety, etc., and achieve good social and economic benefits Benefits, short exhaust time, low engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

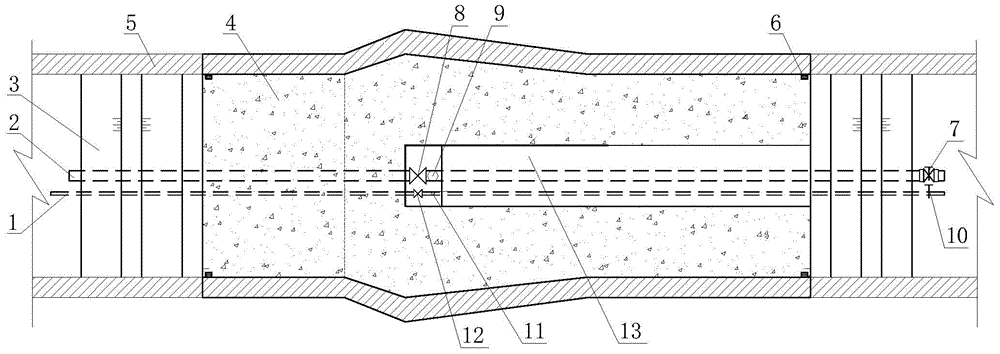

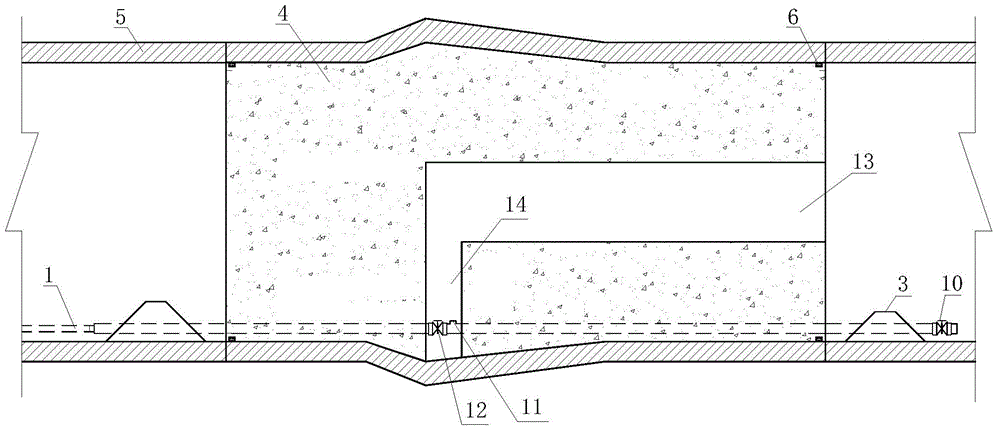

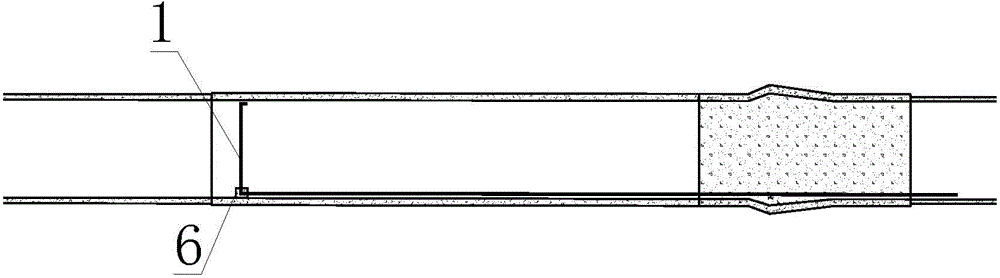

[0035] Such as figure 1 , figure 2 , image 3 As shown, the exhaust structure of a diversion tunnel plugging head according to the present invention includes a diversion cylinder 5 and a concrete plug 4 arranged in the inner sealing area of the diversion cylinder 5, and the bottom of the concrete plug 4 is pre- An exhaust pipe 1 and a drain pipe 2 are buried, and cofferdams 3 are arranged on the upstream and downstream sides of the concrete plug 4 in the guide tube 5, and a grouting gallery 13 and a grouting gallery are also arranged in the concrete plug 4. The gate well 14 that road 13 communicates with. With this technical solution, during construction, the cofferdam 3 is built before the concrete plug 4, and the pre-buried drainage pipe 2 is used to drain water, so as to provide dry ground conditions for the construction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com