A semi-vertical interlocking slope protection block with I-shaped openings

An I-shaped, semi-vertical technology, applied in coastline protection, infrastructure engineering, construction, etc., can solve problems such as high cost, high infiltration water pressure, poor adaptability, etc., to improve construction efficiency, increase mutual engagement, Excellent anti-frost heave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

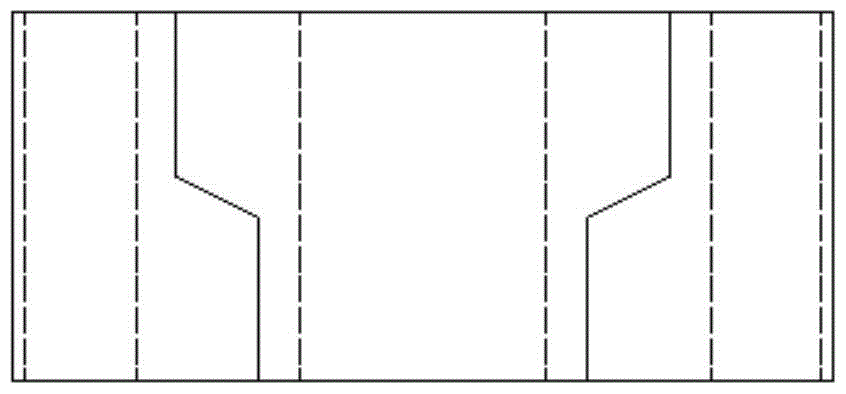

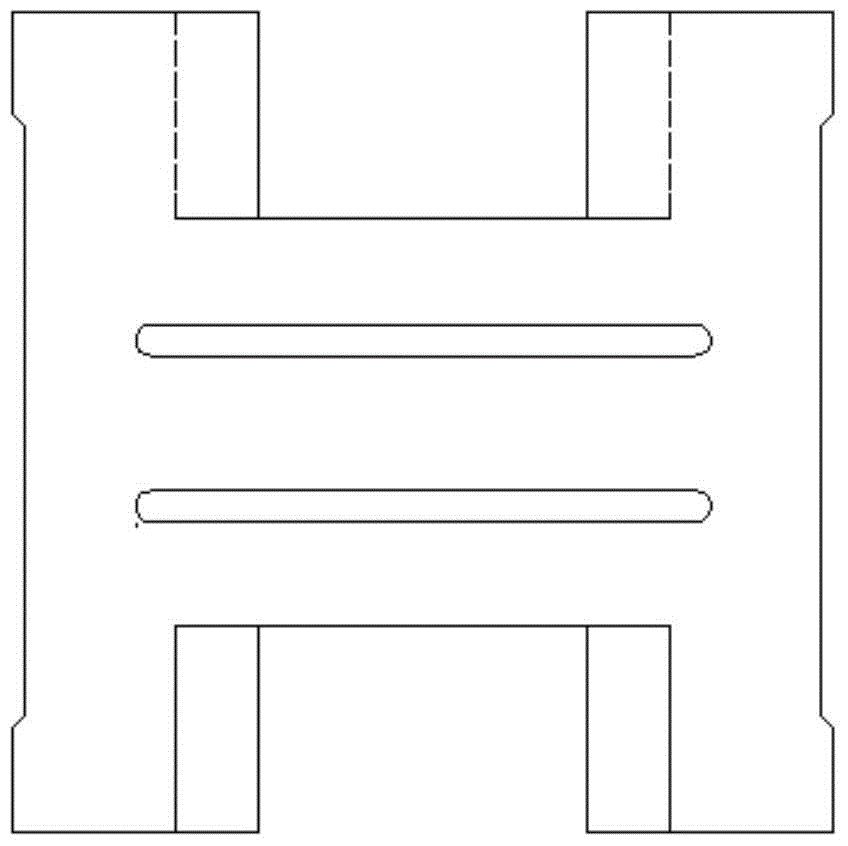

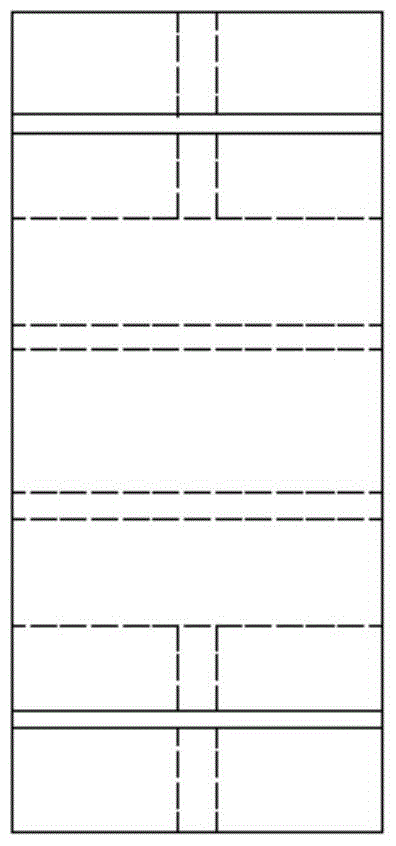

[0035] The present invention is mainly applied in slope protection, where the slope protection refers to the collective designation of various paving and planting done on the slope surface to prevent the slope from being scoured; in order to solve the technical problems proposed in the background technology, the present invention Disclosed a kind of as shown in Fig. 1 (1), Fig. 1 (2), Fig. 1 (3), figure 2 The specific structure of the I-shaped semi-vertical interlocking slope protection blocks with openings shown is as follows:

[0036] Including an I-shaped block, in the two notches formed by the two flanges 1 and the web 2 of the I-shaped block, there are interlocking 3 tenons on the opposite sides of the flange 1, and the interlocking tenons 3 in the same notch Symmetrical to each other, the interlocking tenons 3 located in different notches are set up and down, and there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com