Digital jet printing UV raw lacquer ink prepared by grinding and dispersion and preparation method thereof

A digital jet printing, grinding and dispersing technology, applied in ink, application, household appliances, etc., to achieve the effect of high adhesion, make up for harsh drying conditions and time-consuming, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

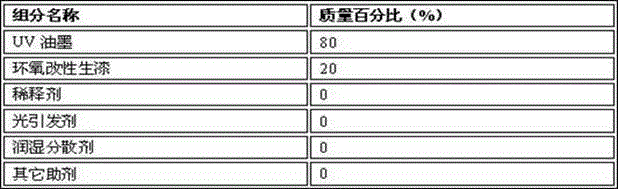

[0038] In the method of preparing digital jet printing UV lacquer ink by grinding and dispersing in this embodiment, the mass percentages of each component are as follows:

[0039]

[0040] According to the above mass ratio formula, epoxy modified raw lacquer is ground and added to UV ink, ultrasonically dispersed for 30 minutes, and filtered to obtain digital jet printing UV raw lacquer ink by grinding and dispersing.

Embodiment 2-5

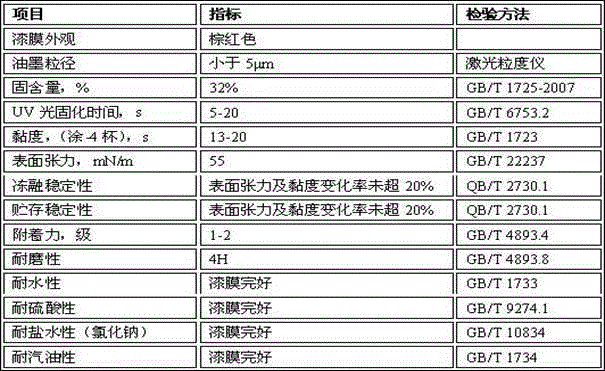

[0042]In the method of preparing digital jet printing UV lacquer ink by grinding and dispersing in this embodiment, the mass percentages of each component are as follows:

[0043]

[0044] According to the above mass ratio formula, add epoxy modified raw lacquer and appropriate amount of UV ink, wetting and dispersing agent, and defoaming agent to the container and stir evenly. Then put it in a grinder, grind for 5-24 hours, then put the ground liquid into a beaker after coarse filtration, add an appropriate amount of UV ink, stir and ultrasonically disperse for 15-30 minutes. Then add an appropriate amount of diluent and additives to prepare the solution to the desired performance index, and use a microporous membrane to filter out the larger particles after coarse filtration. Finally, add an appropriate amount of additives or diluents, stir, and ultrasonically disperse for 15-30 minutes to obtain a digital jet printing UV lacquer ink.

Embodiment 6

[0046] In the method of preparing digital jet printing UV lacquer ink by grinding and dispersing in this embodiment, the mass percentages of each component are as follows:

[0047]

[0048] According to the above mass ratio formula, add epoxy modified raw lacquer and appropriate amount of UV ink, wetting and dispersing agent, and defoaming agent to the container and stir evenly. Then put it in a grinder, grind for 5-24 hours, then put the ground liquid into a beaker after coarse filtration, add an appropriate amount of UV ink, stir and ultrasonically disperse for 15-30 minutes. Then add an appropriate amount of diluent and additives to prepare the solution to the desired performance index, and use a microporous membrane to filter out the larger particles after coarse filtration. Finally, add an appropriate amount of additives or diluents, stir, and ultrasonically disperse for 15-30 minutes to obtain a digital jet printing UV lacquer ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com