Pigment printing thickening agent and preparation method thereof

A paint printing and thickener technology, applied in dyeing, textile and papermaking, etc., can solve the problems of kerosene flammability, resource waste, environmental pollution, etc., and achieve the effect of good stability and not easy to mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

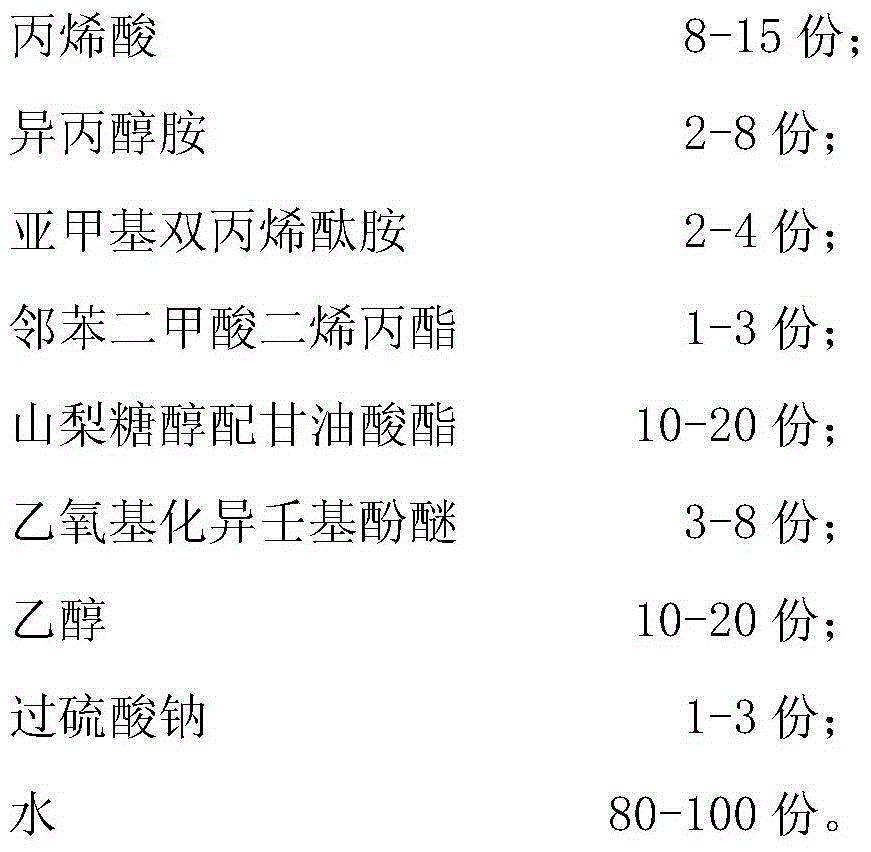

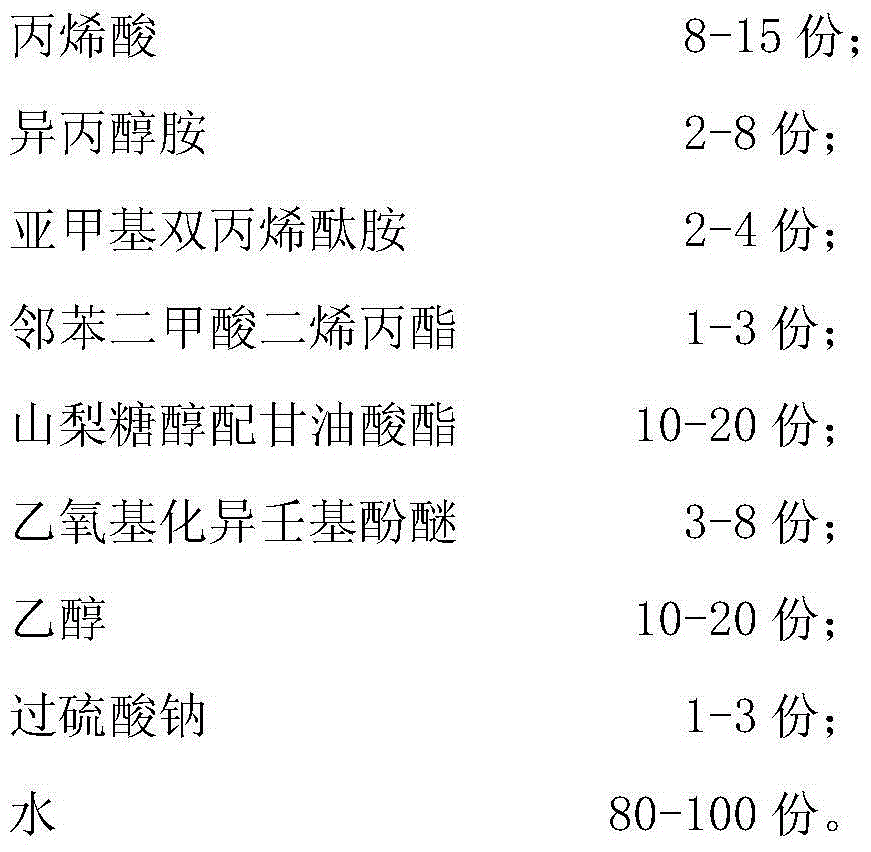

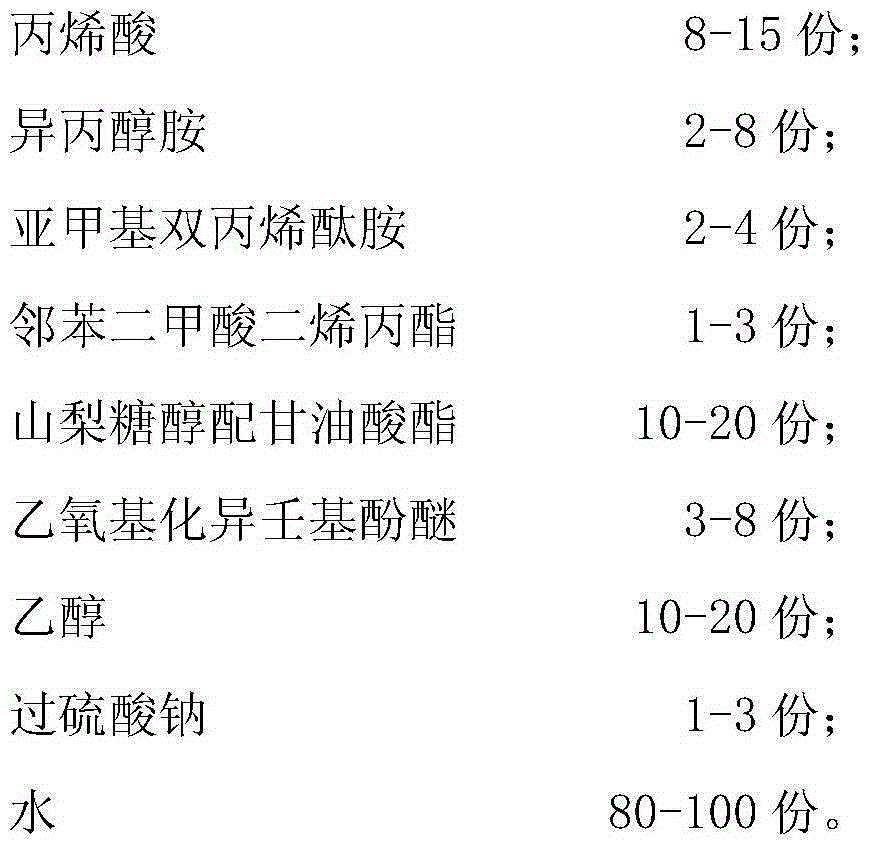

[0017] The preparation method of pigment printing thickener is:

[0018] (1), take each raw material respectively by above-mentioned parts by weight;

[0019] (2), sodium persulfate is added in water, stir and mix;

[0020] (3), heat up the product formed in step (2) to 60-80°C, then add acrylic acid, diallyl phthalate, sorbitol glyceride and ethoxylated isononylphenol ether, React for 3-5 hours;

[0021] (4), add the remaining raw materials, stir and mix evenly to get the product.

Embodiment 1

[0023] Weigh 8 parts of acrylic acid, 2 parts of isopropanolamine, 2 parts of methylenebisacrylamide, 1 part of diallyl phthalate, 10 parts of sorbitol with glyceride, ethoxylated isononyl 3 parts of phenol ether, 10 parts of ethanol, 1 part of sodium persulfate, 80 parts of water, add 1 part of sodium persulfate to 80 parts of water, stir and mix evenly, heat it up to 60 ° C, then add 8 parts of acrylic acid, 1 part Diallyl phthalate, 10 parts of sorbitol with glyceride and 3 parts of ethoxylated isononylphenol ether, react for 3 hours, then add 2 parts of isopropanolamine, 2 parts of methylene bis Acrylamide, 10 parts of ethanol, stir and mix evenly to get the product.

Embodiment 2

[0025] Weigh 10 parts of acrylic acid, 8 parts of isopropanolamine, 4 parts of methylenebisacrylamide, 3 parts of diallyl phthalate, 20 parts of sorbitol with glyceride, ethoxylated isononyl 8 parts of phenol ether, 20 parts of ethanol, 3 parts of sodium persulfate, and 100 parts of water, add 3 parts of sodium persulfate to 100 parts of water, stir and mix evenly, heat it up to 70 ° C, then add 10 parts of acrylic acid, 3 parts of Diallyl phthalate, 20 parts of sorbitol with glyceride and 8 parts of ethoxylated isononylphenol ether, react for 4 hours, then add 8 parts of isopropanolamine, 4 parts of methylene bis Acrylamide, 20 parts of ethanol, stir and mix evenly to get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com