A kind of modified polyurethane suspension filler, preparation method and application thereof

A suspension filler, polyurethane technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc. Improve the effective biomass and functionality, improve the removal rate, and achieve the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

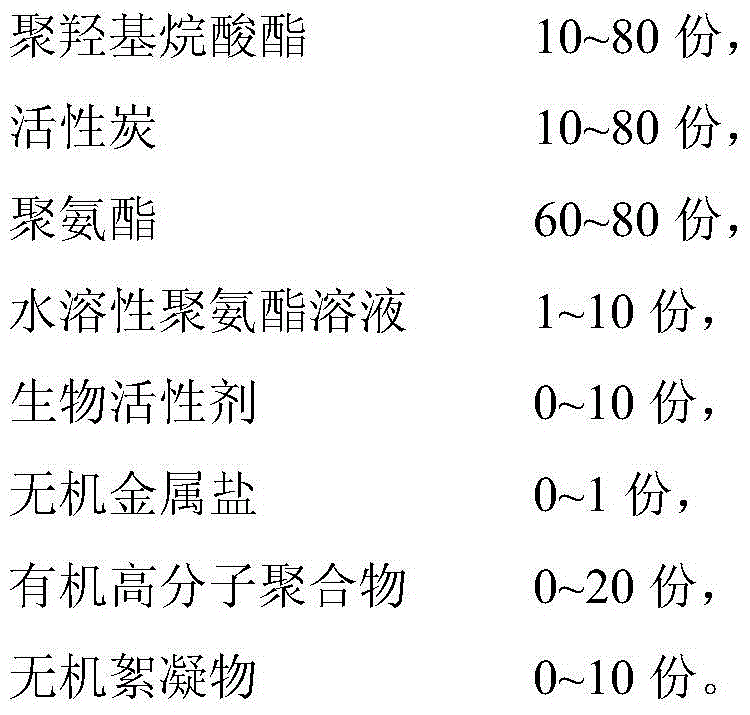

Method used

Image

Examples

Embodiment 1

[0032] Take 80 parts of poly 3-hydroxybutyrate-4-hydroxybutyrate, 10 parts of activated carbon, dissolve in 8 parts of water-soluble polyurethane solution; take 80 parts of ordinary polyurethane filler, soak it in water-soluble polyurethane solution, artificially Knead for 1 hour to obtain a polyurethane suspension filler loaded with polyhydroxyalkanoate, activated carbon and inorganic metal salt; take out the polyurethane suspension filler loaded with polyhydroxyalkanoate, activated carbon and inorganic metal salt from the water-soluble polyurethane solution, and use a small The air blower realizes the preliminary drying of the suspended filler; it is further placed in an oven at about 80°C, and the preparation of the filler is completed after the suspended filler is completely dried.

[0033] Load an appropriate amount of the suspended filler into a 2.2L beaker, add 2L of distribution water consisting of 100mg / L nitrate nitrogen and 20mg / L phosphate, and add an appropriate am...

Embodiment 2

[0035] Take 10 parts of polyhydroxybutyrate valerate (PHBV), 80 parts of activated carbon, and dissolve in 6 parts of water-soluble polyurethane solution; take 60 parts of ordinary polyurethane filler, soak it in water-soluble polyurethane solution, and manually knead it for 1 hour to prepare The polyurethane suspension filler of loading polyhydroxyalkanoate, activated carbon and inorganic metal salt is obtained; the polyurethane suspension filler of loading polyhydroxyalkanoate, activated carbon and inorganic metal salt is taken out from water-soluble polyurethane solution, and utilizes small blower to realize suspension filling Preliminary drying; further put into an oven at about 80°C, and the preparation of the filler will be completed after the suspended filler is completely dried.

[0036] Load an appropriate amount of the suspended filler into a 2.2L beaker, add 2L of domestic sewage in a school residential area, in which the COD in the domestic sewage is 200mg / L, the am...

Embodiment 3

[0038] Take 45 parts of 3-hydroxybutyric acid 3-hydroxyhexanoate and 45 parts of activated carbon, and dissolve them in 7 parts of water-soluble polyurethane solution; take 70 parts of ordinary polyurethane filler, soak them in water-soluble polyurethane solution, and manually knead for 1 hour, Prepare the polyurethane suspension filler loaded with polyhydroxyalkanoate, activated carbon and inorganic metal salt; take out the polyurethane suspension filler loaded with polyhydroxyalkanoate, activated carbon and inorganic metal salt from the water-soluble polyurethane solution, and use a small hair dryer to achieve suspension Preliminary drying of the filler; further put it into an oven at about 80°C, and complete the preparation of the filler after the suspended filler is completely dried. Put the above-mentioned suspended filler into a certain black and smelly closed pond. After 36 days, the black and smelly phenomenon of the closed pond basically disappeared, and some aquatic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com