Bracket for superstructure of ship

A superstructure and bracket technology, applied in the field of brackets, can solve the problems of superstructure bending and deformation, and achieve the effect of convenient and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

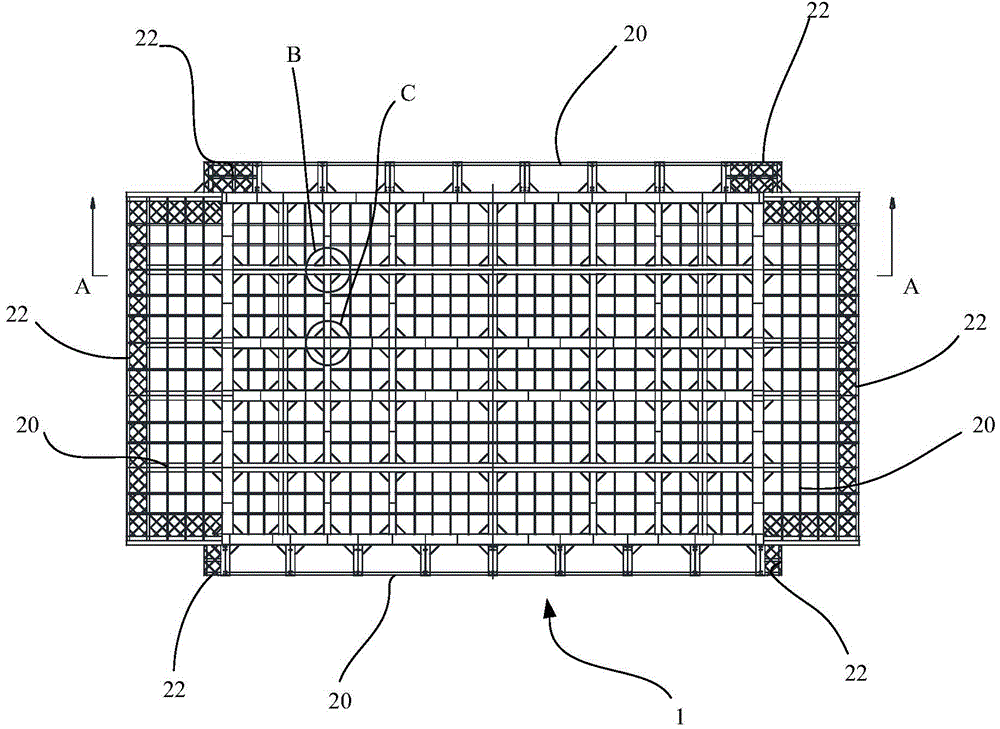

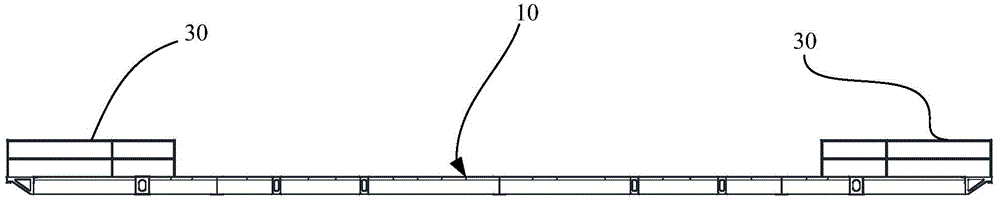

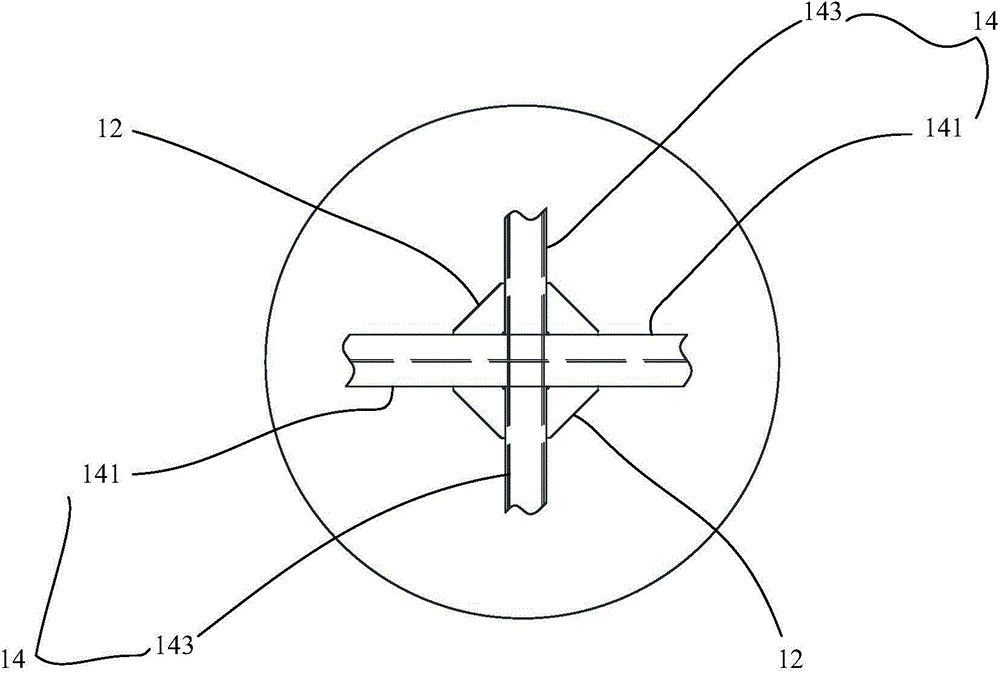

[0049] Figure 1-Figure 6 A bracket for ship superstructure provided by the present invention is shown.

[0050] Such as Figure 1-Figure 4 As shown, the bracket 1 includes a bracket body 10, and the bracket body is welded and fixed by a reinforcing plate 12 and a support beam 14, and the bracket also includes a platform 20 and a railing 30; the platform is arranged on the bracket The surrounding frame body is fixedly connected with the bracket body; the railing is arranged outside the platform and fixedly connected with the platform. The platform in this embodiment is laid with checkered steel plates 22 . Patterned steel plates are laid on the upper end of the platform to provide anti-slip and decorative effects, and provide a good working environment for operators to build superstructures safely.

[0051] Such as image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com