A jig for simultaneously grinding two groups of eccentric circles of crankshafts with double throws and its application method

A double-turn crank and crankshaft technology is applied in machine tools designed for grinding workpiece rotating surfaces, grinding workpiece supports, grinding/polishing equipment, etc., and can solve problems such as inability to guarantee, errors, and difficulty in meeting transmission components, etc. Achieving good application prospects and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

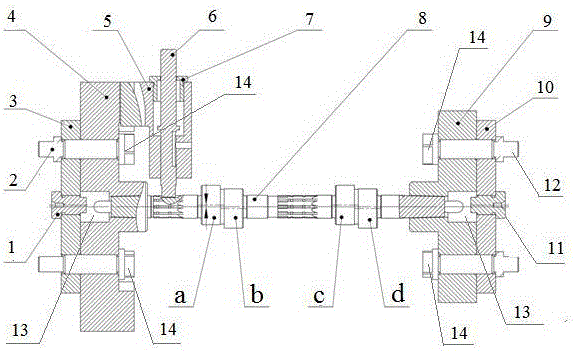

[0028] like figure 1 As shown in the figure, the jig for grinding two sets of double-turn crankshaft eccentric circles at the same time, including the first center hole sleeve 1, the first cylindrical pin 2, the first eccentric plate 3, the first positioning block 4, the spline positioning block 5, the spline Key positioning rod 6, compression nut 7, crank shaft 8, second positioning block 9, second eccentric plate 10, second center hole sleeve 11 and second cylindrical pin 12, the first eccentric plate 3, the second eccentric plate The plates 10 are arranged symmetrically to the left and right, and the eccentric directions are the same. The center hole sleeve 1 and the center hole in the middle of the second center hole sleeve 11 are installed on the grinding mechanism. The first eccentric plate 3 is fixedly connected to the first positioning block 4 through the two fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com