Process industry plantwide control loop oscillation source positioning method based on model identification method

A control loop, process industry technology, applied in the directions of comprehensive factory control, comprehensive factory control, program control, etc., can solve the problem of low accuracy, and achieve the effect of eliminating serious harm and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

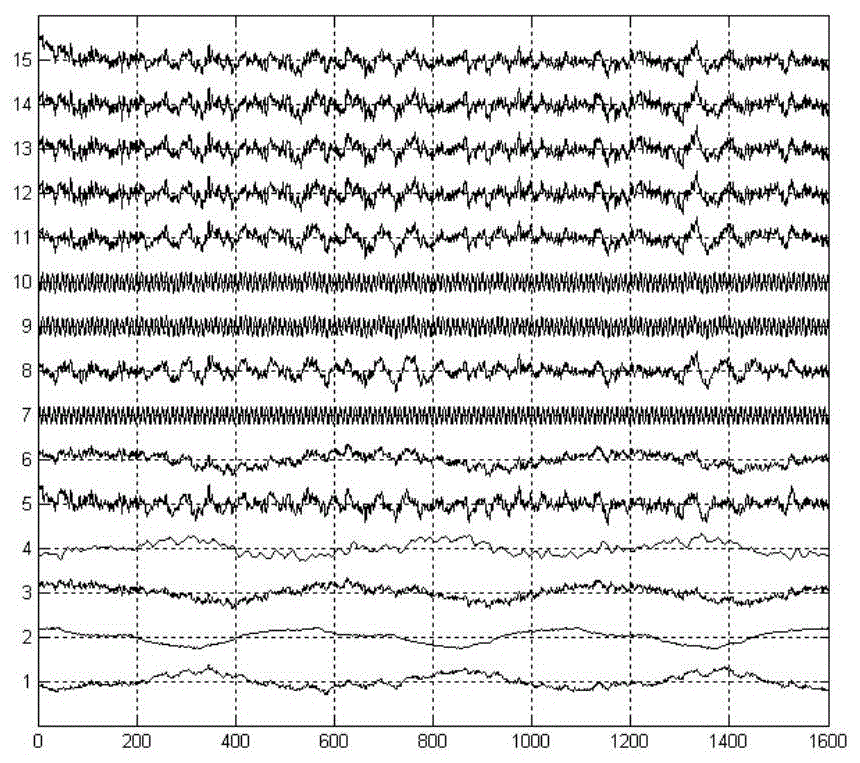

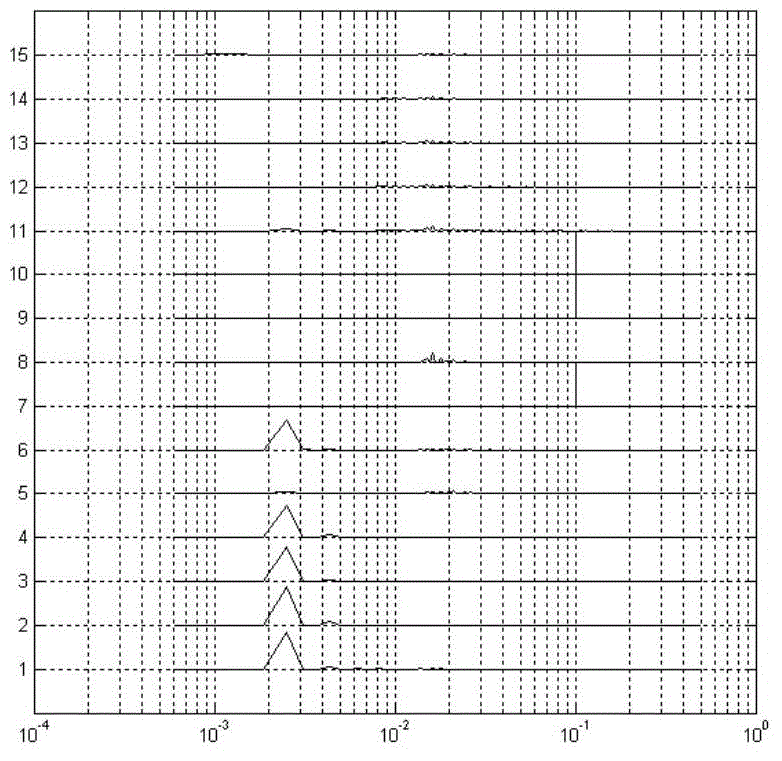

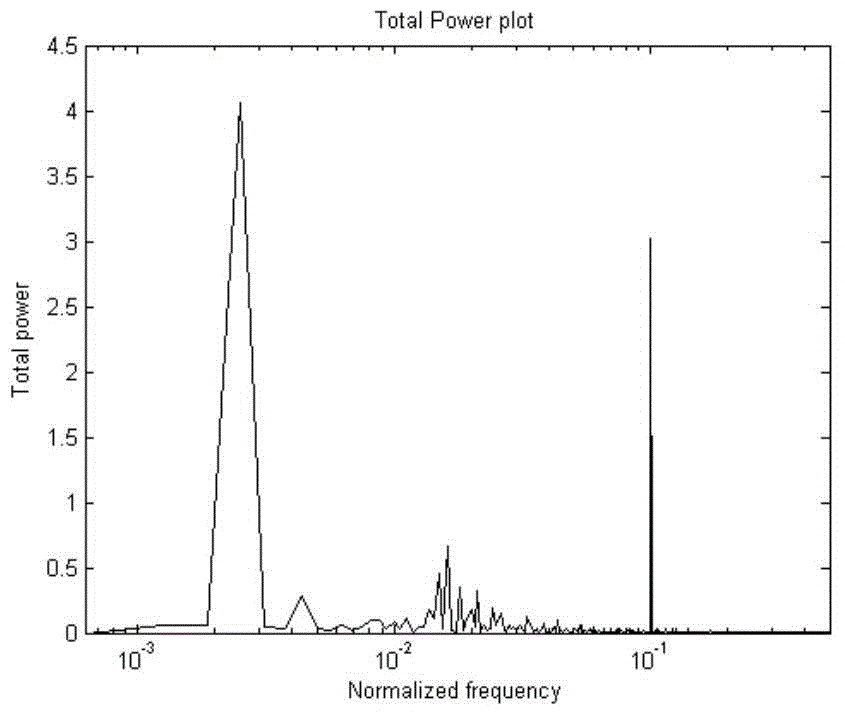

[0016] Specific embodiments of the present invention are described in conjunction with the accompanying drawings. The basic principles of this method for locating the oscillation source of the process industry plant-level control loop are as follows:

[0017] First, assume that in a multi-loop control system with N loops, multi-loop oscillation occurs. That is to say, there are M loops where loop signal oscillation occurs. Obviously, M≤N. An original loop variable data set A that only includes the above M loop signal oscillations is constructed. There are M elements in the data set A which are composed of sampled data sequences of length S. If using matrix A M×S To represent the data set A, then A M×S The dimension of the matrix is: M×S, namely A M×S =[a 1 ,a 2 ,...,a M ] T , where a i (i=1,2,...,M) represents the sampling data sequence of the i-th loop.

[0018] Secondly, for the data set A, combined with frequency-domain non-negative matrix factorization (NMF) or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com