Jack demarcating and calibrating methods

A calibration method and calibration method technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve the problems of manual operation of the oil pump that cannot accurately control the tension of the jack, cannot calibrate the jack, and has large errors, etc., to achieve calibration The results are accurate and reliable, and the effect of overcoming large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

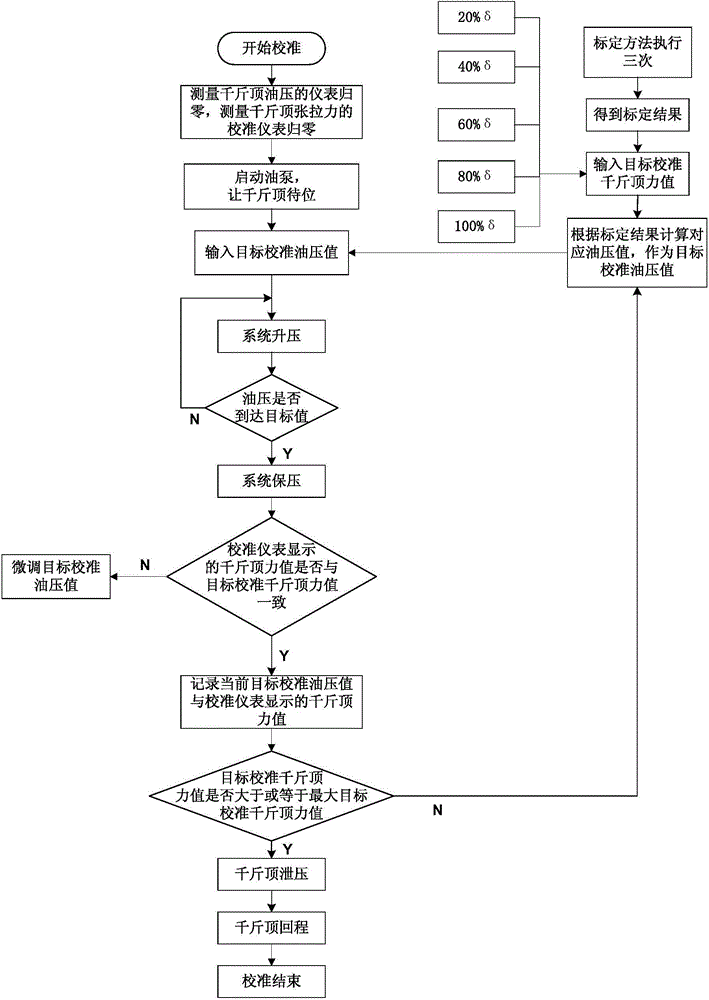

[0034] The invention proposes a method for calibrating and calibrating a jack, which can be automatically carried out in a system composed of a jack and calibrating equipment thereof, and the precision is greatly improved compared with conventional calibrating and calibrating methods.

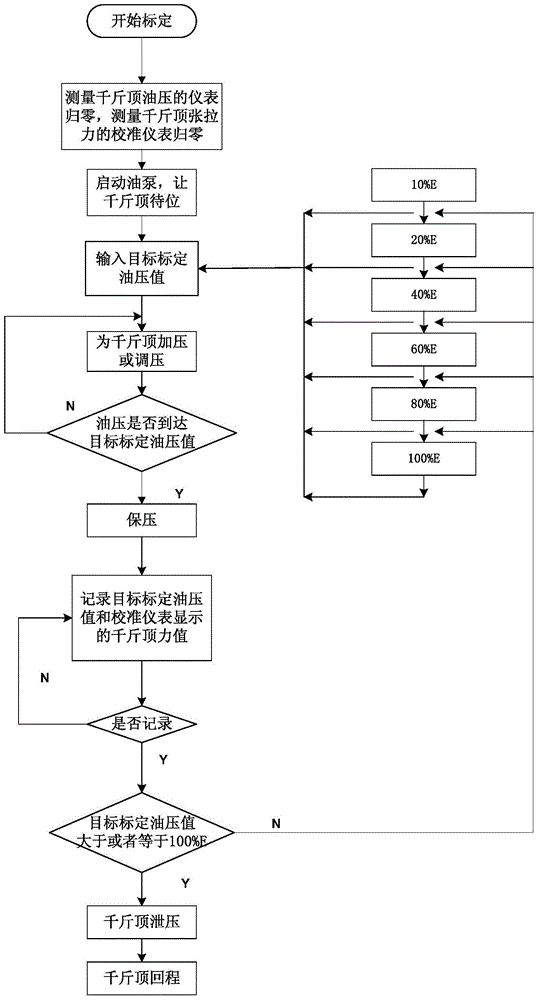

[0035] The calibration method of the jack includes the following steps:

[0036] (1) Set the target calibration oil pressure value sequence, the target calibration oil pressure value sequence includes the first target calibration oil pressure value, the second target calibration oil pressure value, ..., the nth target calibration oil pressure value; wherein, n greater than or equal to 2. The oil pressure mentioned in the present invention all refers to the jack oil pressure.

[0037] Each time a small cycle is performed, a target calibration oil pressure value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com