Dynamic calibration method of portable brake tester

A dynamic calibration and tester technology, applied in vehicle testing, machine/structural component testing, instruments, etc., can solve problems such as difficult dynamic calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

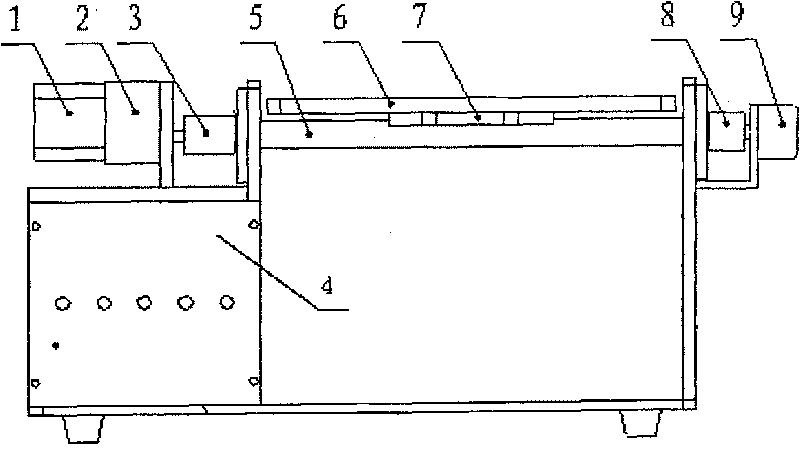

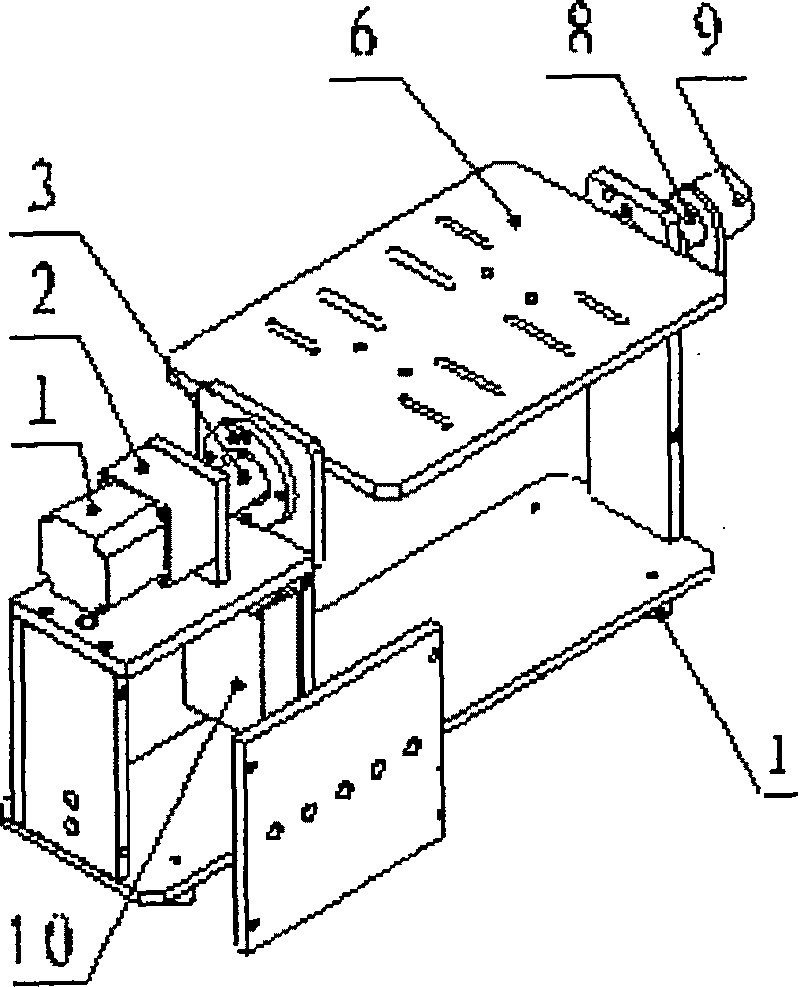

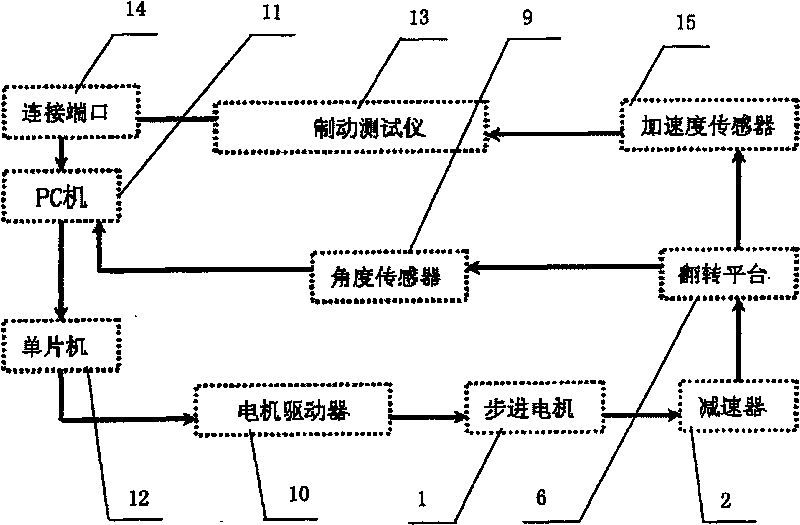

[0030] like Figure 1 to Figure 3 Shown, a kind of dynamic calibration method of portable brake tester, this method comprises the following steps:

[0031] a, the acceleration sensor 15 of the brake tester 13 to be calibrated is installed on the turning platform 6;

[0032] b, the single-chip microcomputer 12 in the control processing module controls the driving mechanism through the motor driver 10, and the rotating shaft 5 is driven to rotate by the driving mechanism;

[0033] c, the angle sensor 9 transmits the angle signal of the rotating shaft 5 measured at different times to the PC 11, and the brake tester 13 transmits the acceleration signal measured at different times to the PC 11;

[0034] d, PC 11 calculates the actual deceleration-time curve according to the input angle signal, PC 11 calculates the actual deceleration-time curve of the brake tester according to the input acceleration signal, and calculates the actual deceleration-time curve The time curve is compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com