Microchannel pressure sensor

A technology of pressure sensors and micro-channels, which is applied in the direction of fluid pressure measurement using capacitance changes, etc., can solve the problems of affecting the liquid flow of micro-channels, increasing the manufacturing process, and being susceptible to interference, so as to improve the degree of integration and cost Inexpensive, less distracting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] figure 1 It is a schematic structural diagram of a micro-channel pressure sensor according to a preferred embodiment of the present invention; the micro-channel pressure sensor in this embodiment includes a fluid channel 7, a side-branch micro-channel 1 of the fluid to be measured, and a micro-capacitance signal measurement Circuit 2, the micro-channel detection section 4 of the side-branch micro-channel 1 of the measured fluid, which is far from the fluid flow channel 7, is bent in the shape of "∪, ∩", and two sides of the micro-channel detection section 4 are symmetrically arranged. The liquid micro-electrode flow channel 3 used to form the liquid metal micro-electrode is both connected to the micro-capacitance signal measurement circuit 2 . The liquid micro-electrode channel 3 is located on both sides of the micro-channel detection section 4 to form a micro-capacitor. The length and number of stages of the micro-channel detection section 4 can be designed according ...

Embodiment 2

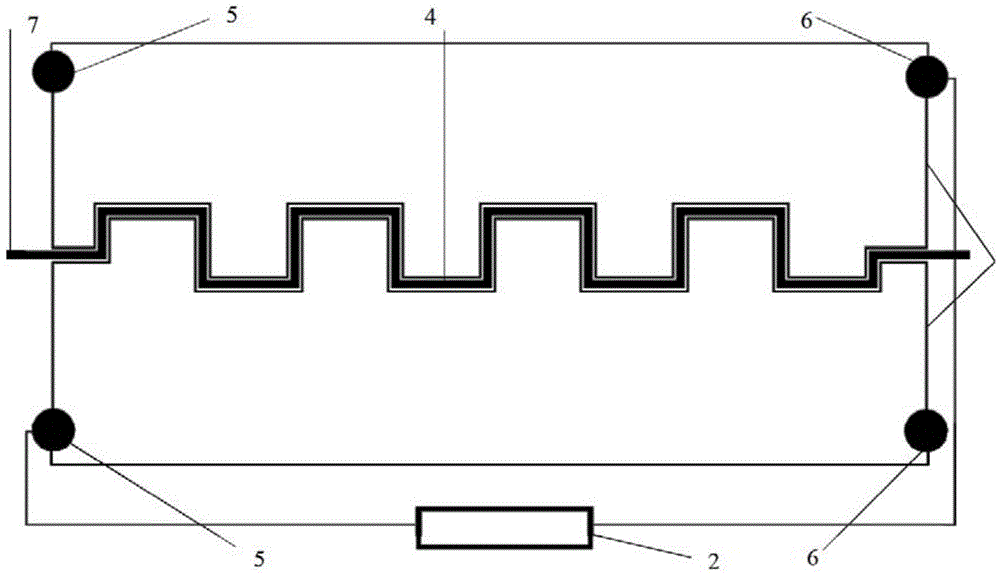

[0029] figure 2 is a schematic structural diagram of a micro-channel pressure sensor according to another preferred embodiment of the present invention; the micro-channel pressure sensor in this embodiment includes a fluid channel 7 and a micro-capacitance signal measurement circuit 2. The fluid channel Two liquid micro-electrode flow channels 3 for forming micro-electrodes are symmetrically arranged on both sides of the micro-channel detection section 4 of 7. The liquid micro-electrode flow channels 3 are parallel to the micro-channel detection section 4 and are used together for constitutes a miniature capacitor. The two liquid micro-electrode flow channels 3 are both connected to the micro-capacitance signal measurement circuit 2 . The micro-channel detection section 4 is bent in the shape of "∪, ∩", and the bending length and series can be designed according to the detection requirements. The liquid micro-electrode flow channel 3 is also bent into a "∪, ∩" shape, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com