Cement kiln head waste heat power generation method and system

A waste heat power generation and cement kiln technology, applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve the problem of low work efficiency of the kiln head boiler, achieve stable main steam temperature, increase waste heat power generation, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

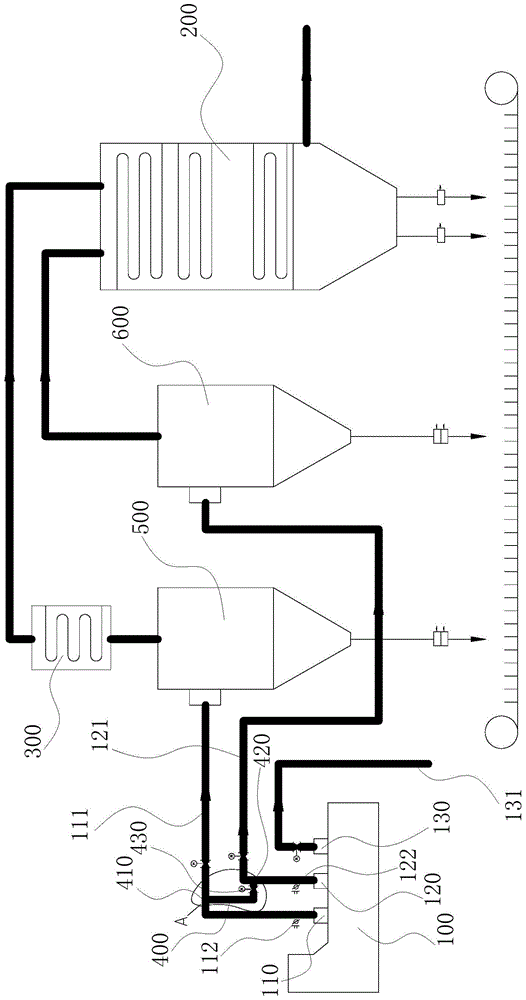

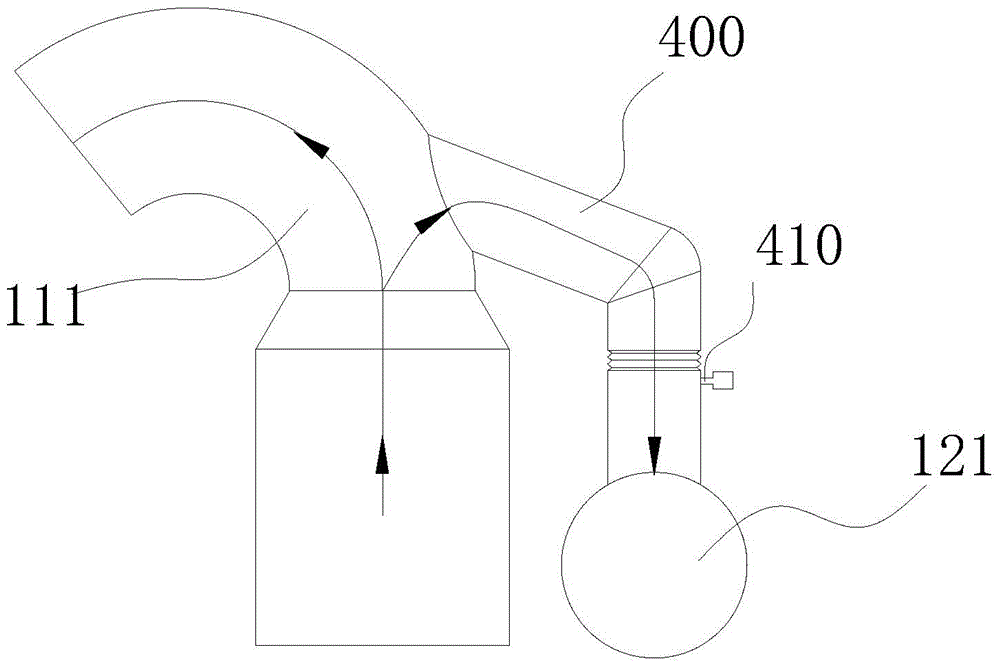

[0034] A cement kiln head waste heat power generation system, taking the 2500t / d clinker production line pure low temperature waste heat power generation project (5.0MW) as an example, the waste heat power generation system includes: grate cooler 100, kiln head AQC furnace 200, high temperature superheater boiler ( ASH superheater) 300, connecting air duct 400, high temperature cyclone vacuum cleaner 500 and medium temperature cyclone vacuum cleaner 600.

[0035] The grate cooler 100 is provided with a high-temperature air outlet 110 , a medium-temperature air outlet 120 and a low-temperature air outlet 130 , and is connected to a high-temperature air pipe 111 , a medium-temperature air pipe 121 and an exhaust gas pipe 131 respectively.

[0036] The kiln head AQC furnace 200 communicates with the medium temperature air duct 121 through a pipeline.

[0037] The high-temperature superheater boiler 300 is provided with a high-temperature superheater boiler gas inlet and a high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com