Rotary compressor and refrigeration cycle device provided with the same

A technology of rotary compressor and compression mechanism, applied in the direction of compressors, irreversible circulatory compressors, components of pumping devices for elastic fluids, etc., to avoid fatigue disconnection and contact with the shell, reduce rotational vibration, Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

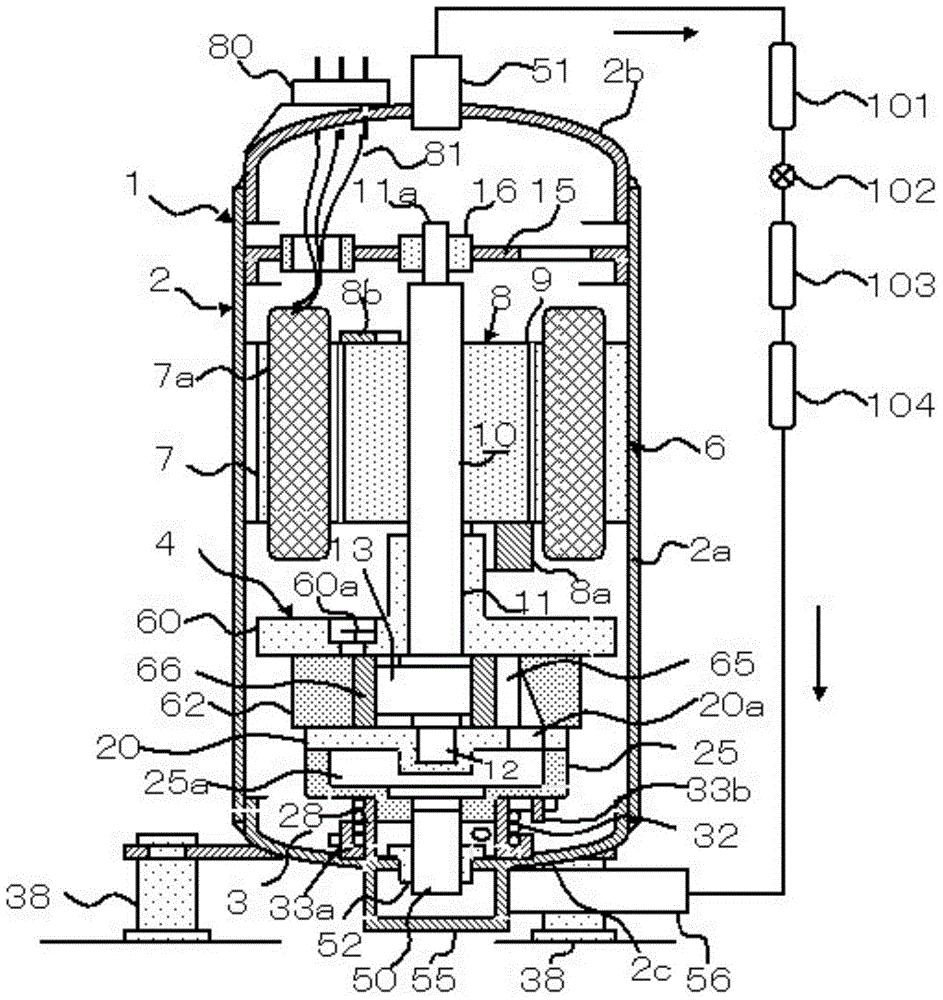

[0049] exist figure 1 The housing 2 of the illustrated rotary compressor 1 accommodates a motor unit 6 and a compression mechanism unit 4 . The motor part 6 is composed of a stator 7 fixed on the inner periphery of the housing 2 and a rotor 8 that rotates while maintaining a certain air gap 9 between the inner diameter of the stator 7. fixed. In addition, a motor coil 7 a is provided in the stator 7 .

[0050] Like the motor of the conventional rotary compressor, the motor unit 6 is selected from an AC motor, a DC inverter motor whose rotation speed can be changed, or the like. For reference, the above-mentioned air gap is about 0.4 to 0.5 mm when installed in a rotary compressor of a home air conditioner, and high-precision concentricity is required between the inner diameters of the rotor 8 and the stator 7 .

[0051] The compression mechanism part 4 is composed of a rolling piston 66 and a slide plate (not shown) housed in a compression chamber 65 formed in a cylinder 62...

Embodiment 2

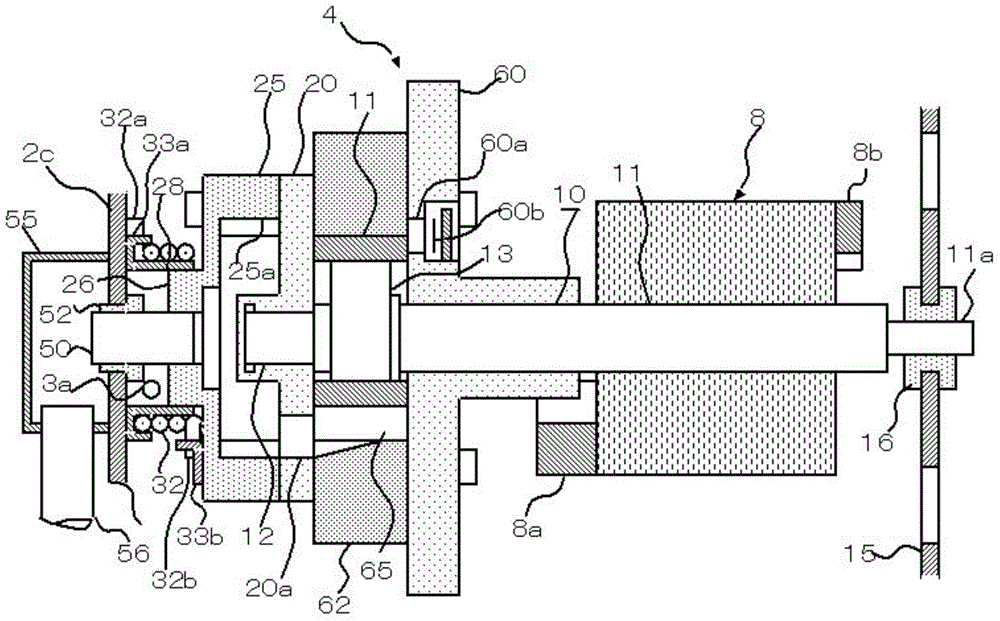

[0074] The present invention is based on the gist that the design can be changed from the viewpoint of improving performance, reliability, and manufacturability. Figure 4In the illustrated compression mechanism unit 4 , the outer periphery of the main bearing 60 is fitted into the main bearing frame 35 provided on the inner periphery of the A casing 2 a. As a result, with the crankshaft 10 supported by the bush 16, the compression mechanism unit 4 can freely rotate repeatedly by two support methods. In addition, by adding the round protrusion support method used in Example 1, a third support method is formed. In addition, instead of the main bearing 60, the outer circumference of the air cylinder 62 may be circular as a supporting means.

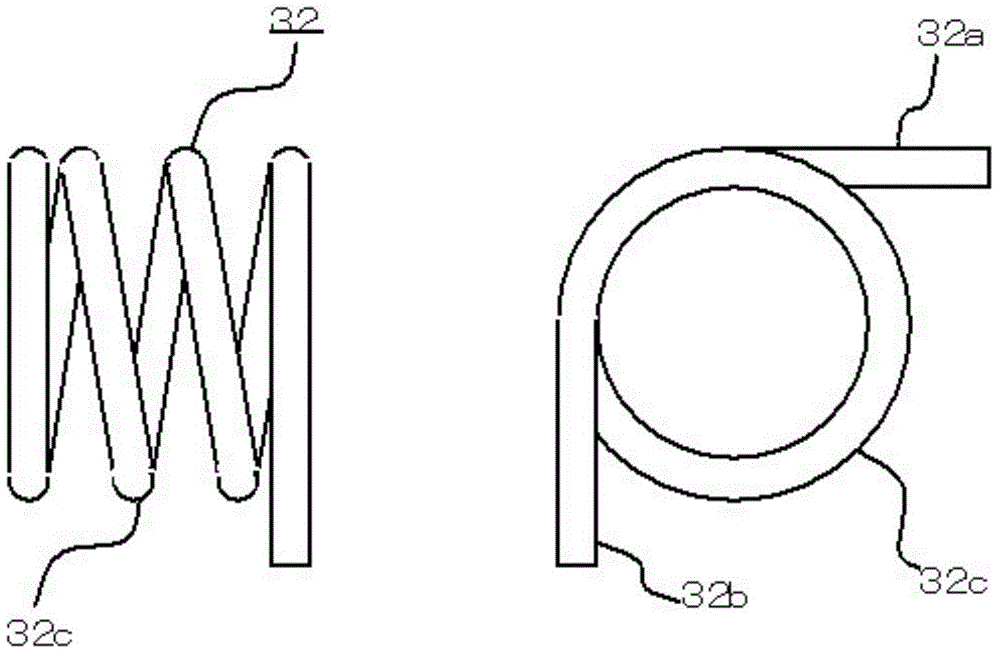

[0075] In the second embodiment, the coil spring 32 provided between the C housing 2c and the circular protrusion 26 supports the load of the compression mechanism part 4, and serves as a buffer device for determining its rotational angula...

Embodiment 3

[0078] exist Figure 5 Among them, the suction hole 20a and the exhaust hole 60a opening to the compression chamber 65 are provided in the main bearing 60 and the sub bearing 20, respectively. That is to say, the parts that arrange the suction hole 20a and the exhaust hole 60a are replaced with those of the first or second embodiment.

[0079] During the operation of the rotary compressor 1, the low-pressure refrigerant sucked from the gas inlet and outlet pipe 51 passes through the motor part 6 from top to bottom, and is sucked into the suction hole 20a. The high-pressure refrigerant compressed in the compression chamber 65 is discharged to the muffler chamber 25a through the exhaust hole 60a, then flows from the gas inlet and outlet pipe 50 to the external muffler 55, and flows out to the external connecting pipe 56. Therefore, the internal pressure of the casing 2 is the low-pressure side of the refrigeration cycle, and the muffler chamber 25a, the gas inlet and outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com