Lead spot welding tooling and line spot welding method for sound films of loudspeakers

A speaker and point-and-line technology, applied in the field of speaker sound film point-and-line tooling, can solve problems such as the inability of the speaker to emit sound, the decrease of the pure sound of the speaker, and the deterioration of the quality of the speaker, so as to avoid fatigue disconnection, reduce the overall load, and improve the sound quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments.

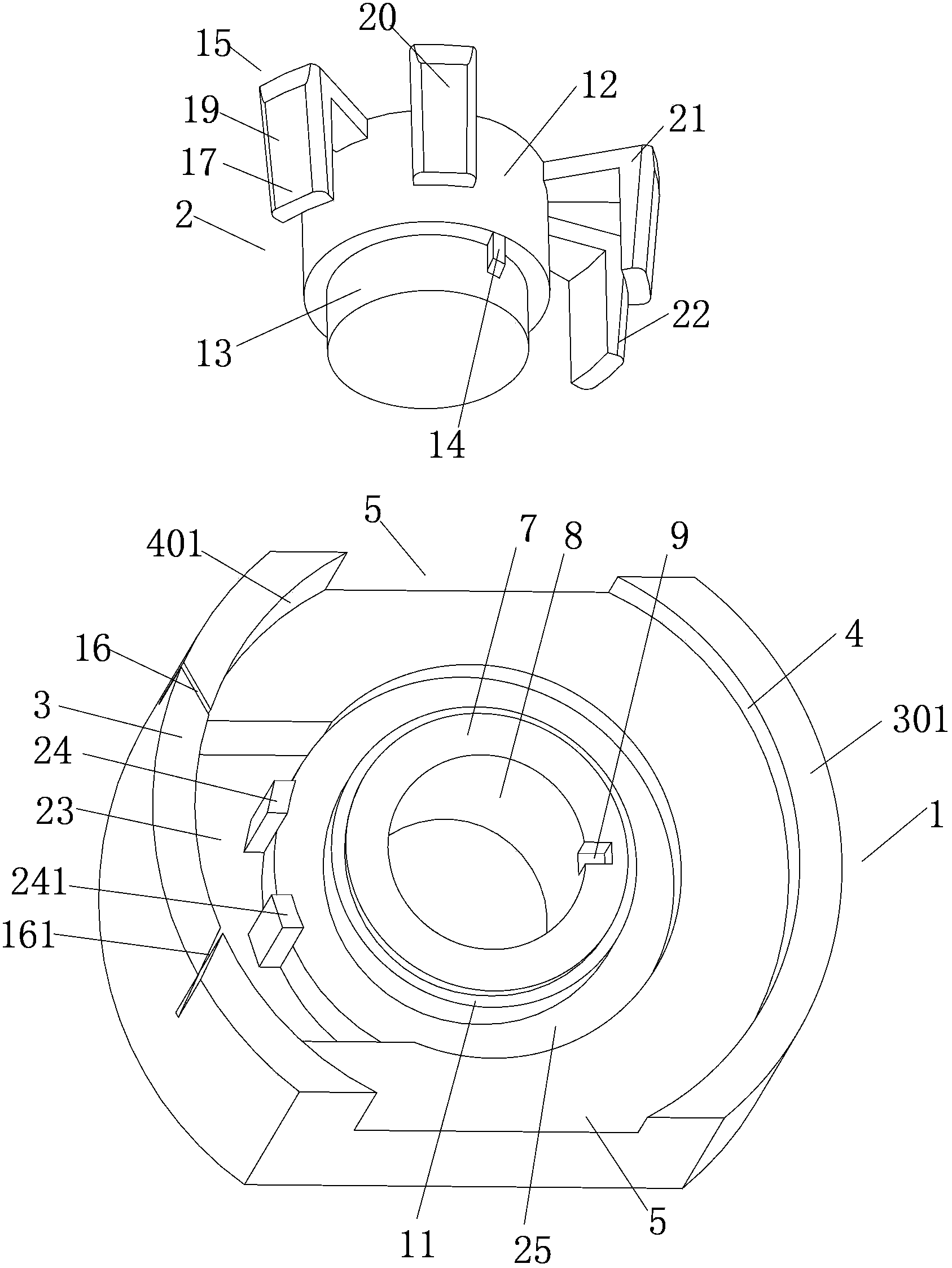

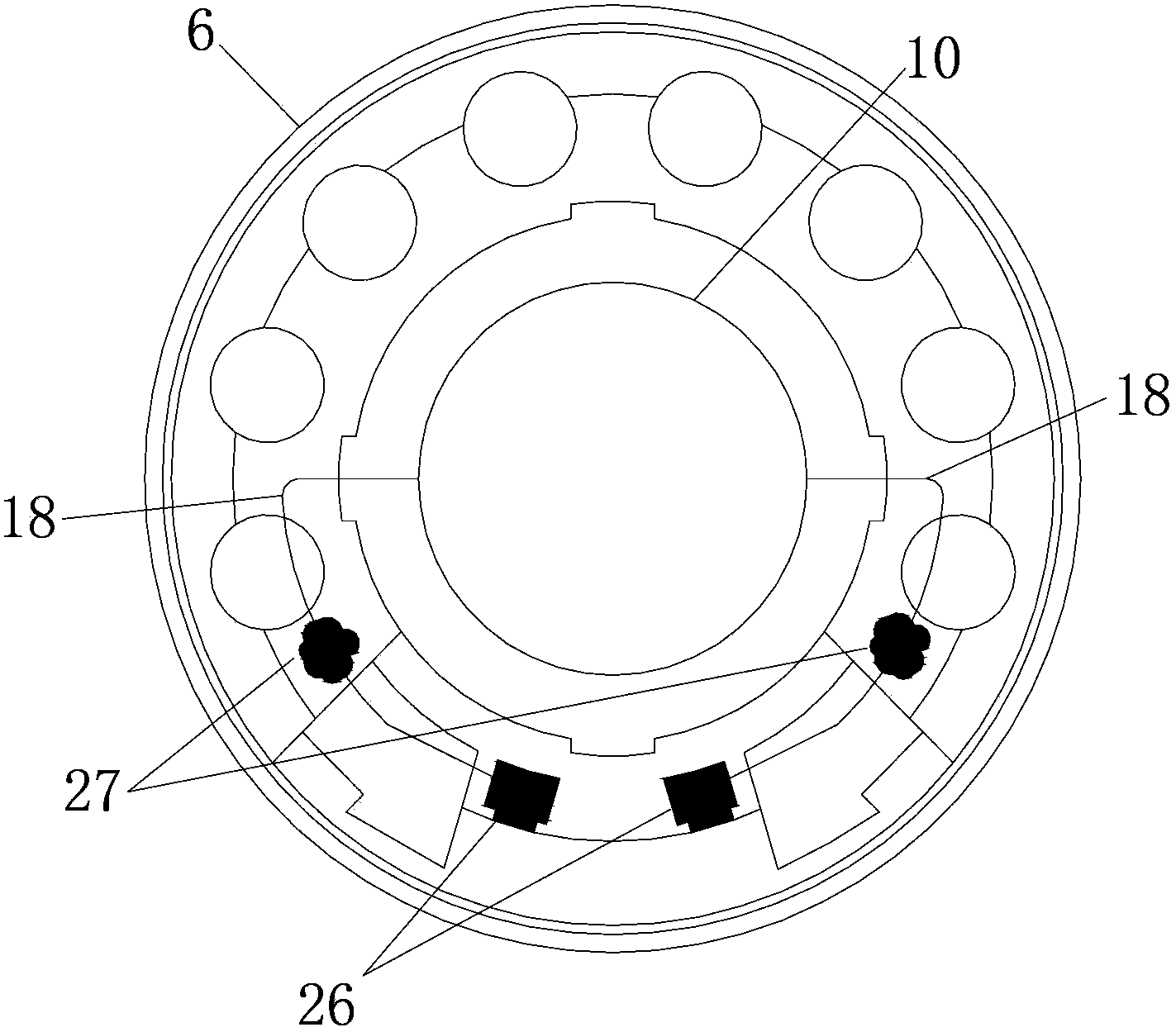

[0026] See figure 1 , 2 , Loudspeaker sound film dot-line tooling, which includes a lower base 1, an upper pressure base 2 arranged on the lower base 1 and matched with the lower base; the upper end surface of the lower base 1 is provided with two upwardly protruding arc limiting ribs 3 301, there are two arc-shaped limiting ribs, the limiting surfaces 4 and 401 of the two arc-shaped limiting ribs are on the same circle, and there is a gap between the two arc-shaped limiting ribs 5. It is convenient to take and place the basin frame 6, and when the round basin frame 6 is placed on the lower base 1, it is limited by two arc-shaped limiting ribs 3 and 301, so that the basin frame cannot be left or right. , Move back and forth; the clamping cuts 16, 161 are set on one of the arc-shaped limit ribs 3; the upper end surface of the lower base 1 is provided with a rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com