A scr injection metering module and control method

A technology of injection module and control method, which is applied in the direction of electric control, exhaust gas treatment, mechanical equipment, etc. of exhaust gas treatment device, can solve problems such as affecting normal operation and cooling, difficulty in production and maintenance, and large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

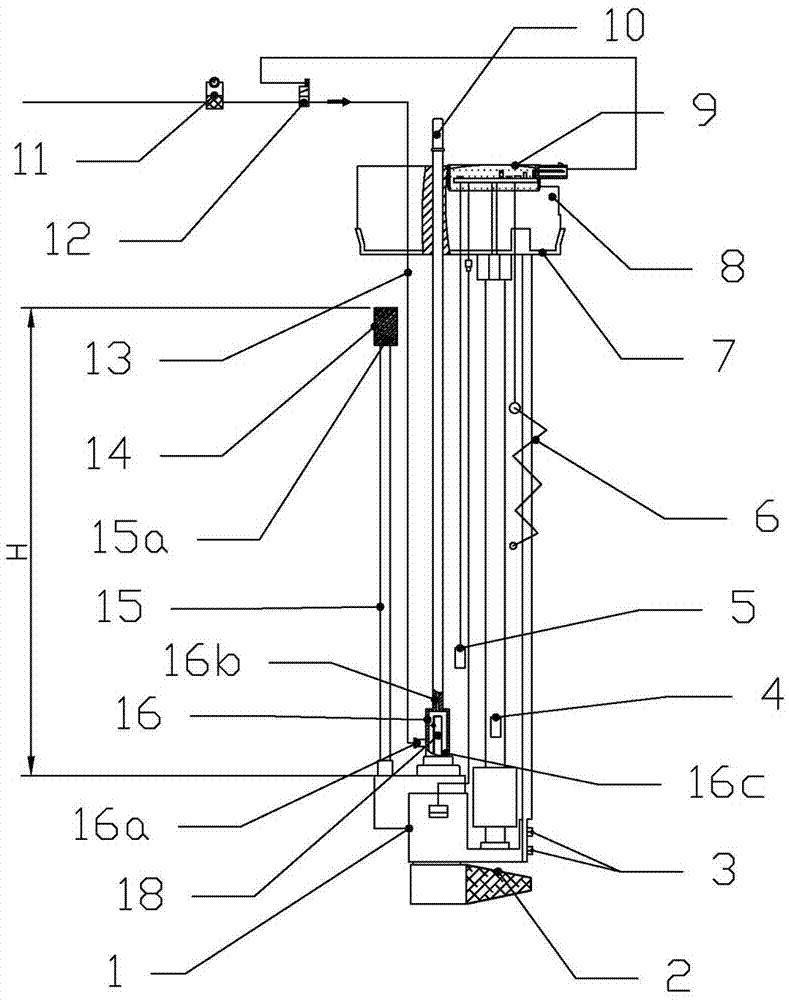

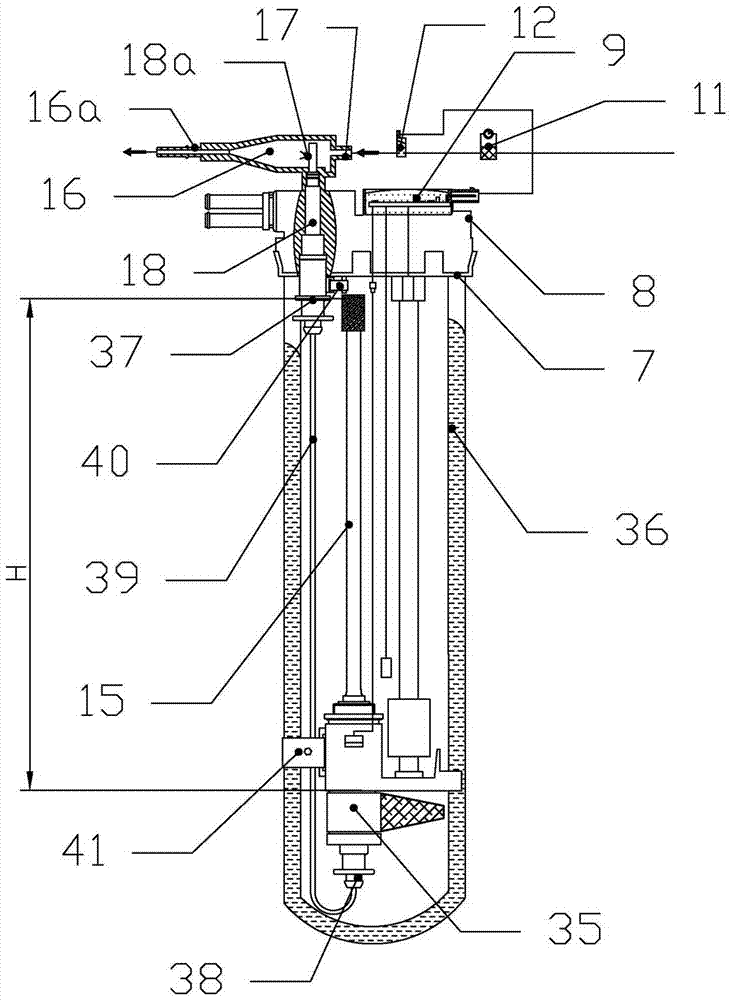

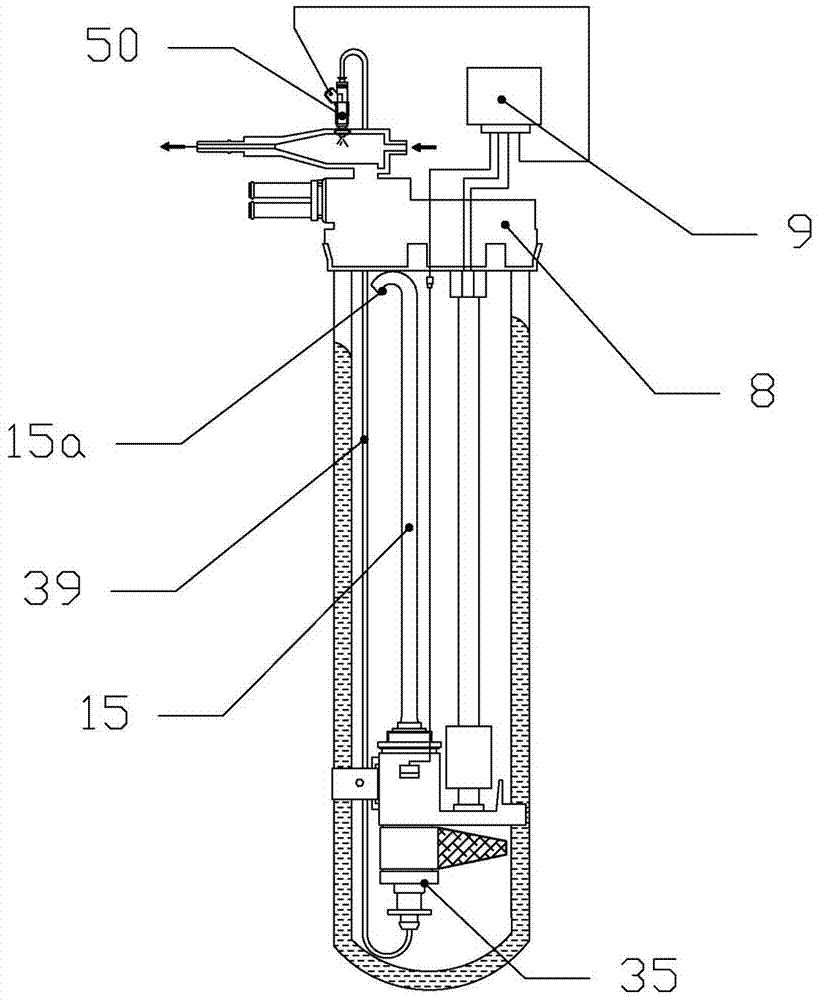

[0075] Such as figure 1 As shown, the structure diagram of the first embodiment of the SCR metering injection module provided by the present invention includes a pulse pump 1, a bracket 7, a nozzle 18, a gas-liquid mixing chamber 16, a controller 9, an upper end cover 8, a delivery pipe 10, and a filter Pressure regulating valve 11, compressed air control solenoid valve 12, compressed air pipe 13. The pulse pump 1 and the upper end cover 8 are installed on the two ends of the bracket 7 respectively, and the pulse pump 1 is fixedly connected with the bracket 7 as a whole through the screw thread 3 at the lowermost end of the bracket 7 . Upper end cover 8 is fixed on the upper end of support 7, and both can be a whole. The support 7 is also equipped with an electrically heated ice melter 6 , a liquid level sensor 4 and a temperature sensor 5 . The controller 9 is installed on the upper end cover 8, and the electrical connection lines on the bracket 7, including pulse pump driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com