FRP soundproof door

A soundproof door and door body technology, applied in the direction of soundproof doors/windows, door leaves, door/window accessories, etc., can solve the problems that affect the appearance of the whole door, the overall appearance is uncoordinated, easy to be corroded, etc., and achieve simple structure , good thermal insulation effect, and the effect of ensuring the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

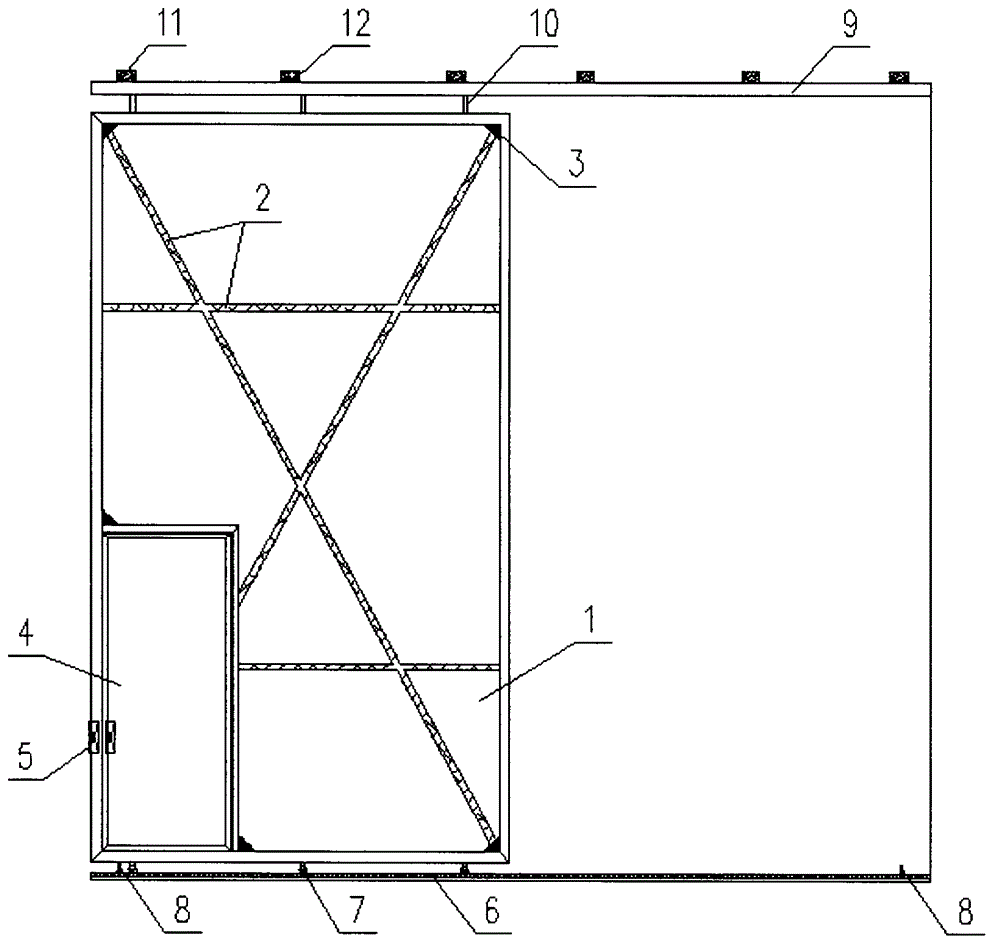

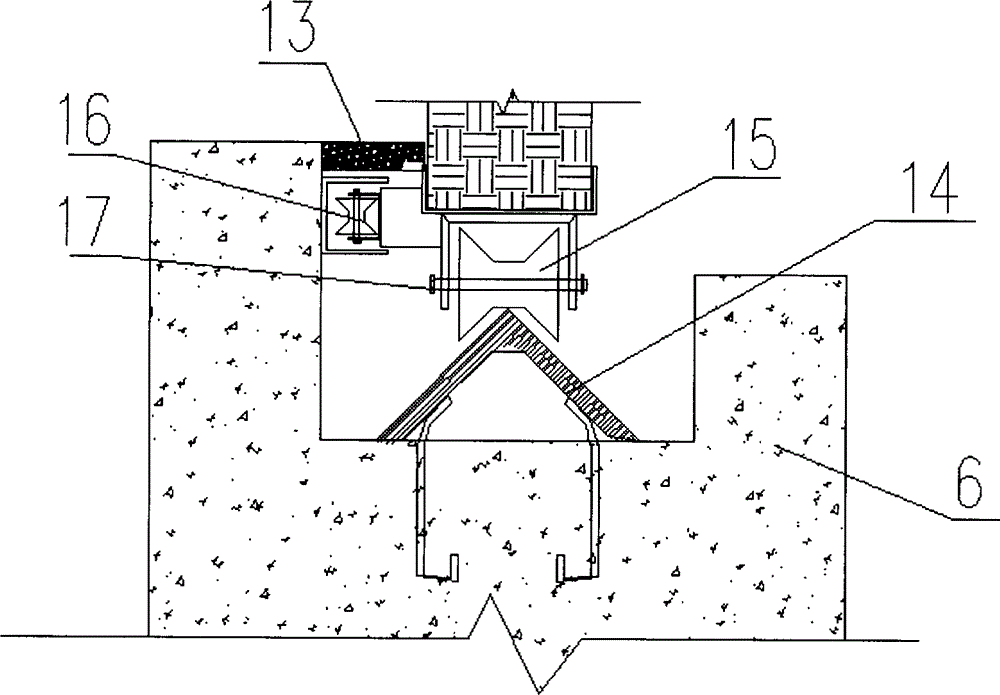

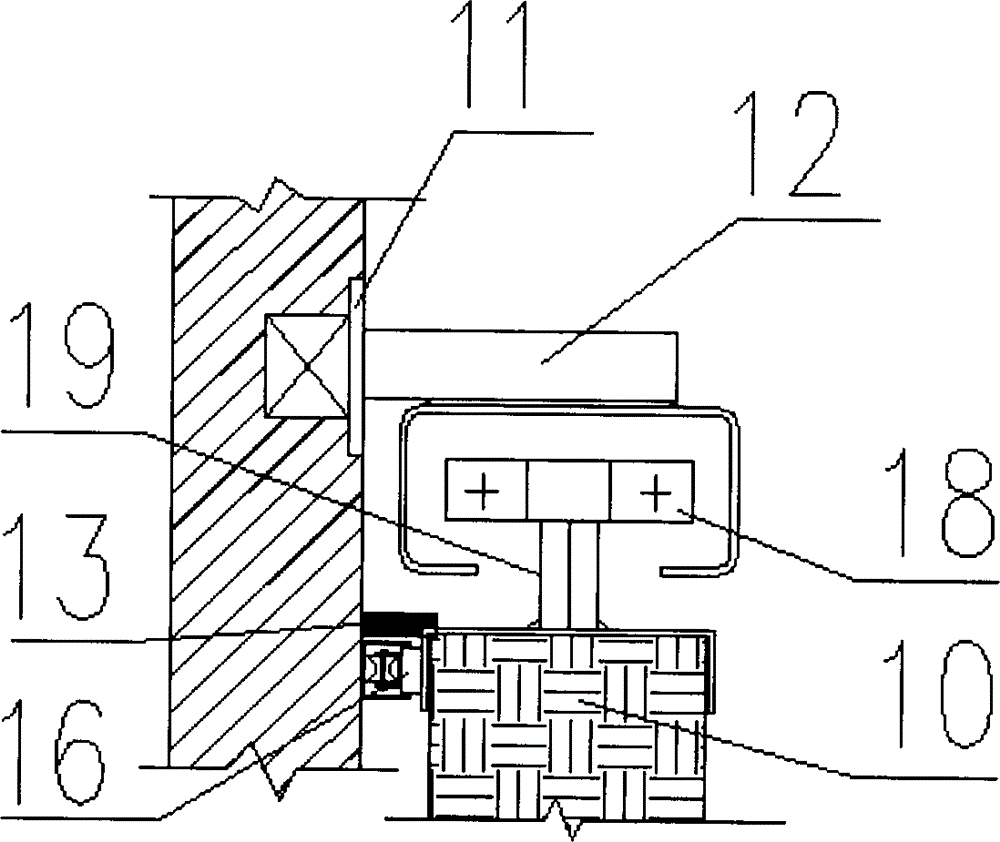

[0018] Example: such as figure 1 As shown, a FRP soundproof door of the present invention includes a door body 1 and a bottom chute 6 arranged on the top pulley groove 9 and the bottom of the door body 1, and the door body 1 is a door body 1 composed of FRP honeycomb sandwich panels. ; The pulley groove 9 is provided with a steel plate 11, the steel plate 11 is provided with a channel steel 12, and a bearing 18 is installed in the channel steel 12, and the bearing 18 is sleeved on one end of the rotating shaft 19, and the other end of the rotating shaft 19 The door body 1 is connected by a connecting rod 10 passing through the pulley groove 9; a triangle steel 14 is arranged inside the bottom pulley groove 6, and a bottom pulley 7 is arranged between the door body 1 and the triangle steel 14. The pulley 15 is rolled and mounted on the bracket of the pulley 7 through a pin shaft 17; a sound insulation strip 13 is arranged between the pulley groove 9 and the bottom chute 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com