T-shaped concrete filled steel tube specially-shaped column applied to industrial production

A technology of concrete-filled steel tubes and special-shaped columns, applied in the directions of columns, piers, pillars, etc., can solve the problems such as the inability of industrialized mass production of concrete-filled steel tube special-shaped columns, the inability to guarantee the quality of special-shaped columns, and the unfavorable industrial production. The effect of reduced residual deformation, less on-site welding workload, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

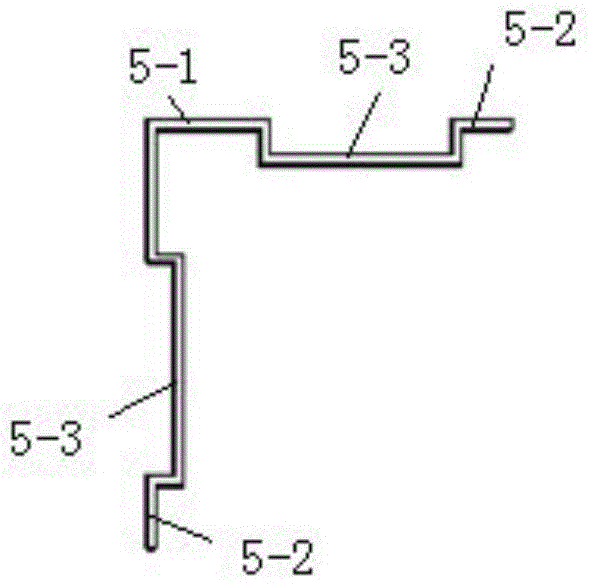

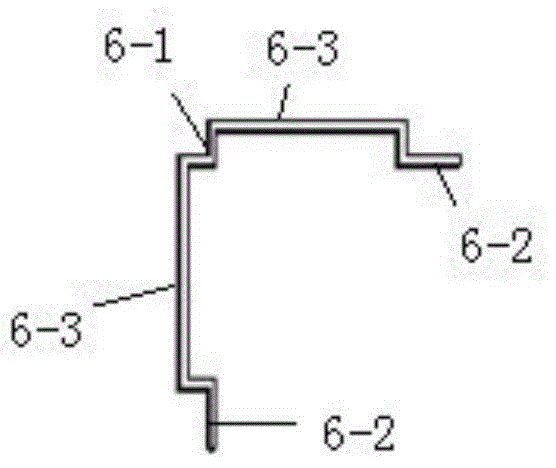

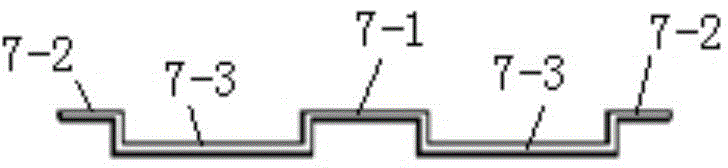

[0019] The present invention provides a series of prefabricated concrete-filled steel pipe special-shaped columns, using steel plates of four different cross-section types as shown in Figure 1 and Figure 3, and forming steel plates of different cross-section types by combining steel plates of any of several cross-section types Concrete Steel Tube special-shaped column. through butt welds and figure 2 Connect 4 steel plates with 3 cross-sections into L-shaped concrete filled steel tube special-shaped columns with long through bolts, or connect 6 steel plates with 3 cross-sections into a T-shaped cross-section through butt welds and bolts Concrete-filled steel tube special-shaped column, or 8 steel plates with two cross-section forms connected by butt welds and bolts to form a cross-section concrete-filled steel tube special-shaped column, see Figure 4 and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com