Acetic fermentation expanding cultivation and acid steaming process and system

An acetic acid fermentation and acid steaming technology, applied in the field of microbial fermentation, can solve the problems of hindered fermentation speed of acetic acid bacteria, prolonged expansion period, long adaptation period of bacteria, etc., so as to improve the breeding environment of acetic acid bacteria, shorten the delay period, The effect of reducing thermal energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

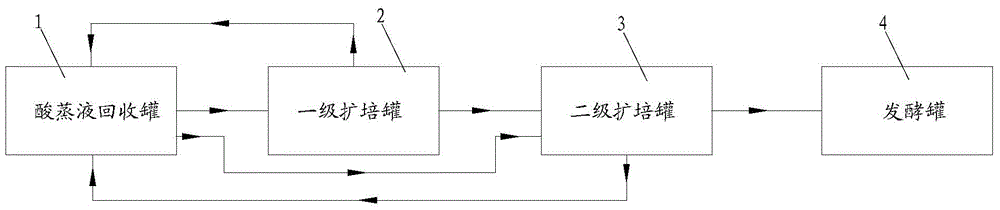

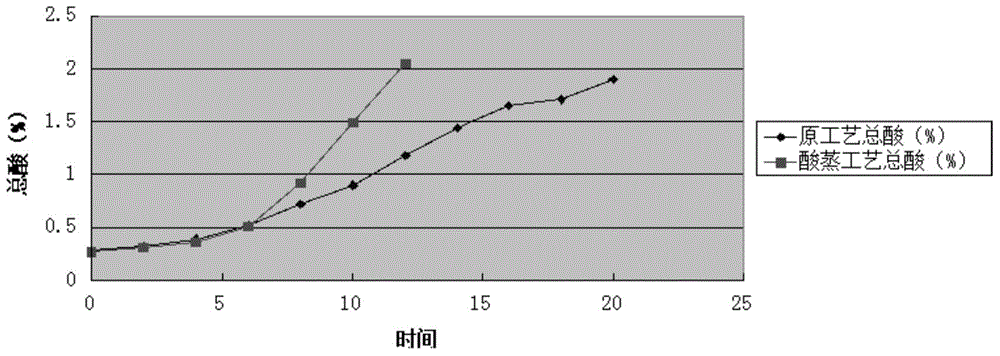

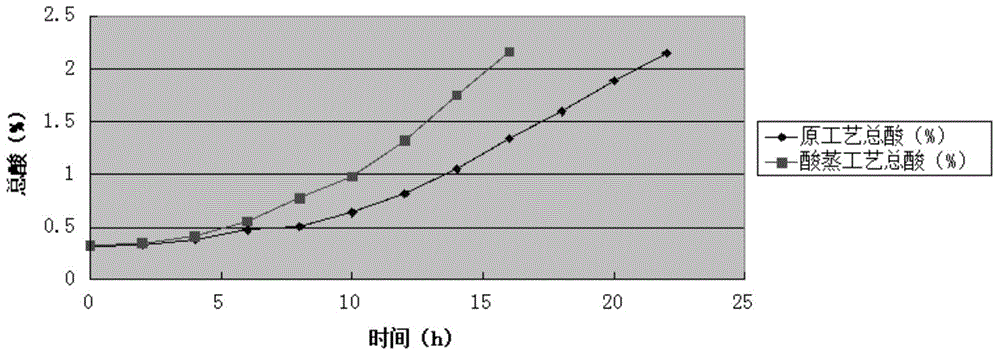

[0031] A kind of acetic acid fermentation expanding cultivation acid steaming process described in the present embodiment comprises the following steps:

[0032] 1) Pretreatment: First, carry out CIP alkaline washing and hot water cleaning on the first-level expansion tank; then send the wine vinegar into the first-level expansion tank for acid steaming. The process conditions for acid steaming are: control the addition of wine vinegar The amount is 1 / 5 of the capacity of the tank, and the total acid of wine vinegar is not less than 3%; the stirring speed of the first-stage expansion tank is controlled to 780rpm to ensure the uniform distribution of steam in the tank, and it is heated to 90°C and kept for 20 minutes , and then the wine vinegar is discharged, and the discharged wine vinegar is transported to the acid steam recovery tank for recovery through pipelines, and the total acid of wine vinegar in the acid steam recovery tank is measured. When the total acid is lower tha...

Embodiment 2

[0046] The feature of this embodiment is: control the stirring speed of the primary expansion tank to 900rpm, so as to ensure the uniform distribution of steam in the tank. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com