Water-based wood paint and preparation method thereof

A water-based wood paint, water-based technology, applied in the field of coatings, can solve the problems of long drying time, poor wear resistance, complicated process, etc., and achieve the effect of short film forming time, high wear resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: a kind of water-based wood lacquer, is configured by weight part by following composition:

[0018] 40 parts of water-based polyurethane acrylate resin, 30 parts of methyl benzoate-butyl acrylate copolymer, 0.3 parts of thickener, 1 part of photoinitiator, 0.5 parts of defoamer, 0.2 parts of dispersant, 0.2 parts of leveling agent 15 parts, 15 parts of filler, 11 parts of co-solvent, 100 parts of water.

[0019] To prepare the above wood lacquer, first fully mix the water-based polyurethane acrylate resin and methyl benzoate-butyl acrylate copolymer, then add the photoinitiator and stir for 10 minutes, then add the thickener, defoamer, and dispersant in sequence , leveling agent, and filler were stirred for 15 minutes, and then added co-solvent and water within 1 minute to obtain a water-based wood varnish after dispersion.

Embodiment 2

[0020] Embodiment 2: a kind of water-based wood lacquer, is configured by weight part by following composition:

[0021] 48 parts of water-based polyurethane acrylate resin, 38 parts of methyl benzoate-butyl acrylate copolymer, 0.6 parts of thickener, 1.2 parts of photoinitiator, 0.5 parts of defoamer, 0.2 parts of dispersant, 0.2 parts of leveling agent 15 parts, 15 parts of filler, 11 parts of co-solvent, 110 parts of water.

[0022] To prepare the above wood lacquer, first fully mix the water-based polyurethane acrylate resin and methyl benzoate-butyl acrylate copolymer, then add the photoinitiator and stir for 10 minutes, then add the thickener, defoamer, and dispersant in sequence , leveling agent, and filler were stirred for 18 minutes, and then added co-solvent and water within 1 minute to obtain a stable water-based wood varnish after dispersion.

Embodiment 3

[0023] Embodiment 3: a kind of water-based wood lacquer, is configured by weight part by following composition:

[0024] 55 parts of water-based polyurethane acrylate resin, 45 parts of methyl benzoate-butyl acrylate copolymer, 0.9 parts of thickener, 2 parts of photoinitiator, 0.5 parts of defoamer, 0.2 parts of dispersant, and 0.2 parts of leveling agent 15 parts, 15 parts of filler, 11 parts of co-solvent, 120 parts of water.

[0025] To prepare the above wood lacquer, first fully mix the water-based polyurethane acrylate resin and methyl benzoate-butyl acrylate copolymer, then add the photoinitiator and stir for 10 minutes, then add the thickener, defoamer, and dispersant in sequence , leveling agent, and filler were stirred for 20 minutes, and then added co-solvent and water within 1 minute to obtain a water-based wood varnish after dispersion.

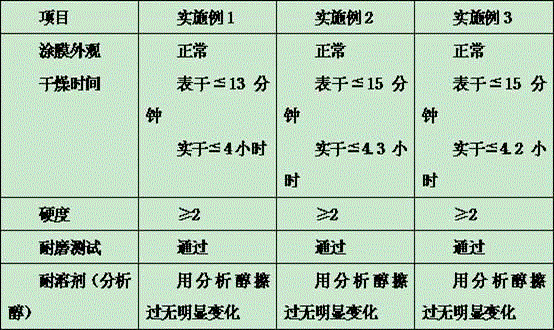

[0026] The performance test data of the embodiment of the present invention 1-3 sees the following table:

[0027]

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com