Fluoropolyether-containing polymer-modified silane, surface treating agent, and article

一种表面处理剂、表面处理的技术,应用在表面处理剂处理的制品,改性硅烷和/或其部分水解缩合物的表面处理剂,聚合物改性的硅烷领域,能够解决催化剂效率低、影响性能等问题,达到优异防水/防油性、长期保持防污性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0175] Examples of the present invention are given below by way of illustration and not limitation.

Synthetic example 1

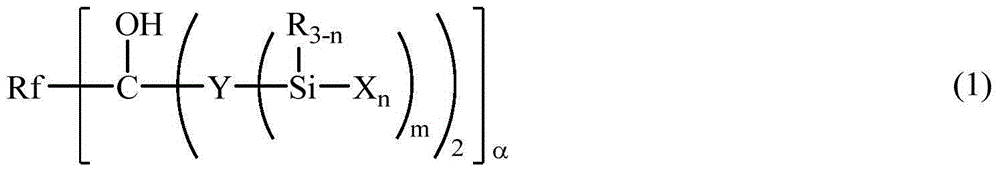

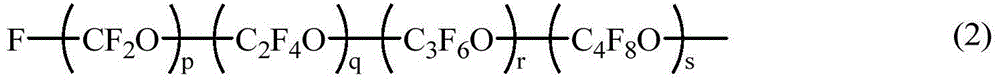

[0177] 150 g of tetrahydrofuran and 300 g of 1,3-bistrifluoromethylbenzene were charged into the reactor, and 160 ml of 0.7M allylmagnesium bromide was added dropwise thereto. Next, slowly add 300g (4.8×10 -2 mol) a compound of the following formula (I).

[0178]

[0179] The resulting solution was heated at 60 °C for 4 hours. It was then cooled to room temperature and added dropwise to 300 g of 1.2M aqueous hydrochloric acid to terminate the reaction. The lower layer or fluorine compound layer was recovered by separation operation and washed with acetone. The washed lower layer or fluorochemical layer is recovered again. The residual solvent was distilled off in vacuo to obtain 292 g of a fluoropolyether-containing polymer of the following formula (II).

[0180]

Embodiment 1

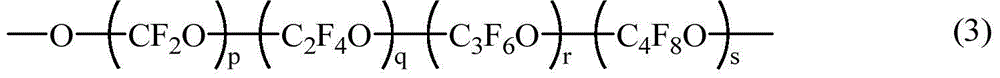

[0182] 200g (2.6×10 -2 mol) has the compound of formula (II) shown below, 200g 1,3-bis(trifluoromethyl)benzene, 12.7g (1.1×10 -1 mol) trimethoxysilane and 6.0×10 -1 g of chloroplatinic acid / vinylsiloxane complex (containing 1.6×10 -5 mol Pt) in toluene, mix them.

[0183]

[0184] The solution was aged at 80°C for 40 hours. The solvent and unreacted reactants were then distilled off in vacuo. The remaining low-boiling and high-boiling fractions were subsequently removed, still by molecular distillation, to obtain 100 g of liquid product.

[0185] Through NMR analysis, it was determined that the product had the structure of the following formula (III).

[0186]

[0187] 1 H-NMR

[0188] δ0.2-2.2(-C H 2 C H 2 C H 2 -)12H

[0189] δ3.0-3.5(-Si(OC H 3 ) 3 )18H

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com