A two-way variable speed screwdriver

A technology of screwdriver and speed change device, which is applied to screwdrivers, wrenches, wrenches, etc. It can solve the problems of affecting the control of the operator's force, high cost, and damage to the thread, so as to improve work efficiency, high work efficiency, and force. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

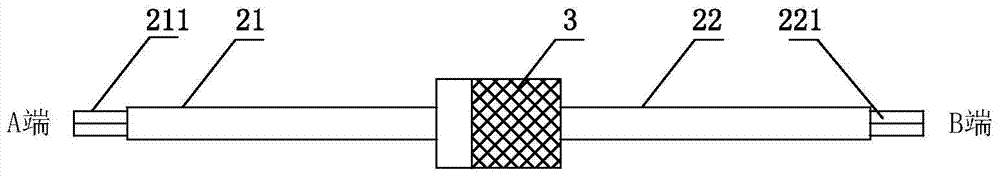

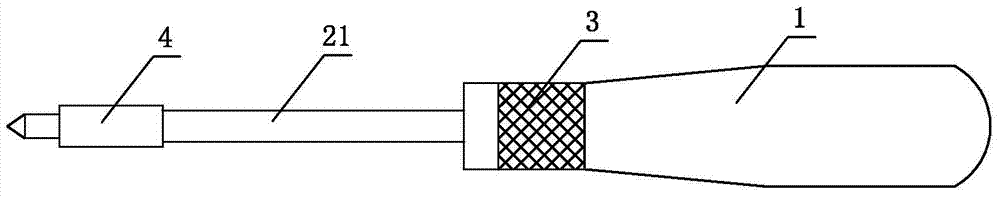

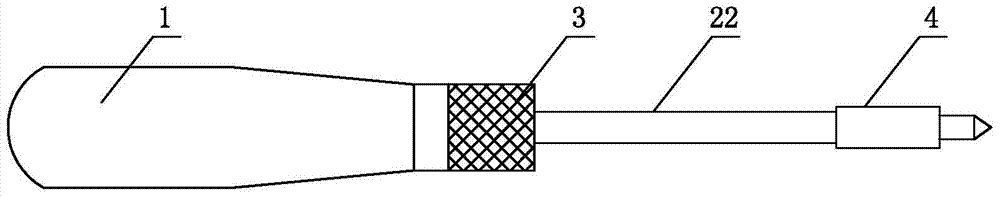

[0032] A two-way variable speed screwdriver, comprising a movable handle 1, a sleeve cutter head 4, a screwdriver rod and a two-way speed change device 3, the screwdriver rod is a two-way screwdriver rod, including an A cutter rod 21 and a B cutter rod 22, and the A cutter rod The tool rods A and B are respectively connected to the left and right ends of the two-way transmission device, and the ends of the A cutter rod and the B cutter rod are respectively provided with hexagonal connecting ends;

[0033] There is a long blind hole 11 in the center of the movable handle, and the bottom end of the long blind hole is a hexagonal blind hole 12 matched with the hexagonal connection end of the A tool bar or B tool bar; the movable handle is socketed on the A tool bar or the B tool bar When the rod is on, its hexagonal blind hole is positioned in coordination with the hexagonal connecting ends at the ends of the A knife bar and the B knife bar, so that the movable handle drives the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com