Variable-frequency edge grinding machine and grinding method thereof

An edging machine and grinding technology, which is applied to machine tools, metal processing equipment, grinding/polishing equipment, etc., which are suitable for grinding workpiece edges, can solve problems affecting product quality, low work efficiency, and low precision, and achieve The grinding method is simple and quick, the work efficiency is high, and the effect of saving labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

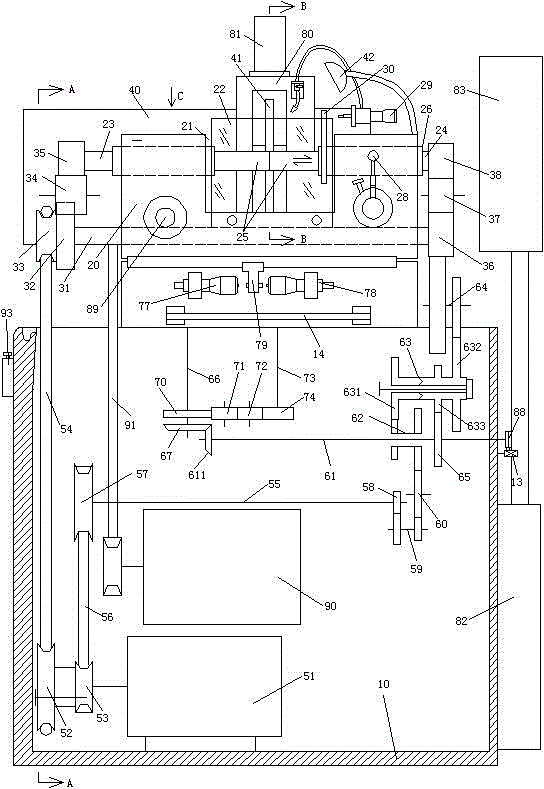

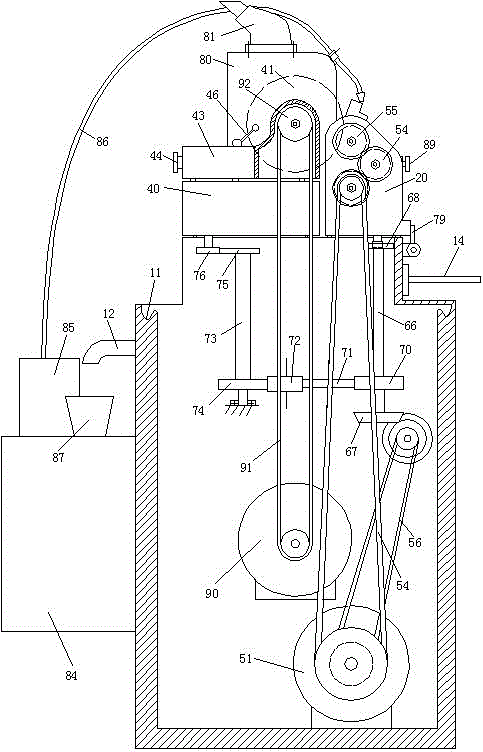

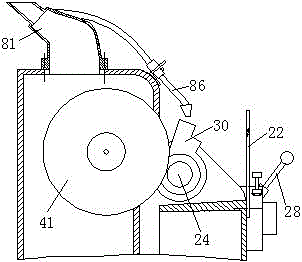

[0025] refer to Figure 1 to Figure 5

[0026] A frequency conversion edging machine, comprising a frame 10, the frame is a cabinet with a hollow inside, the upper part of the frame is provided with a head box 20 with an operating port 21 in the middle and can move back and forth laterally, the operating port The front side is provided with a transparent droplet protection plate 22 . One side of the head box is provided with a horizontal rotating shaft 23 driven to rotate by a variable speed drive mechanism, one end of the horizontal rotating shaft penetrates into the operation port transversely, and the other side of the head box is provided with a horizontal rotating shaft driven by a variable speed drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com