Positioning and stamping die

A technology for stamping dies and stamping components, which is applied in the field of molds and can solve problems such as the shape deviates from the expected shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

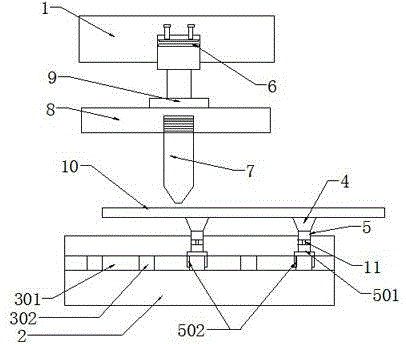

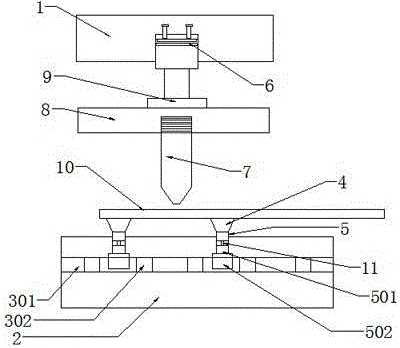

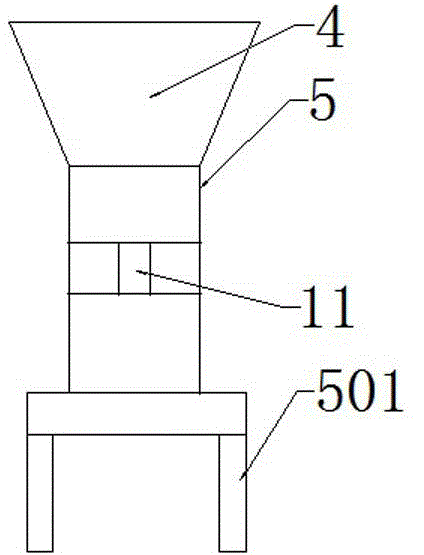

[0023] A positioning stamping die, comprising: an upper mold base 1, a lower mold base 2, as for the stamping assembly on the upper mold base 1, a clamping track provided in the lower mold base 2, which is clamped on the clamping track and carries a product 10 The positioning assembly, the positioning assembly includes: the clamping block 5 clamped on the clamping track, as for the suction cup 4 on the clamping block 5; in order to have detachable and stable fixation, and to buffer the impact force of the punch 7 on the product 10, as One preference, the suction cup 4 is a plastic suction cup 4 . The clamping track consists of: a plurality of horizontal tracks 301, a plurality of longitudinal tracks 302 intersecting the horizontal tracks 301; the longitudinal tracks 302 are perpendicular to the upper horizontal track 301; The length and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com