Bending device based on intelligent adjustment and control

A bending device and intelligent adjustment technology, applied in the field of sheet metal processing, can solve the problems of inability to adjust the thickness of the sheet in real time, lack of angle control devices, and low processing quality of the sheet, so as to prevent excessive bending, improve processing quality, and facilitate adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

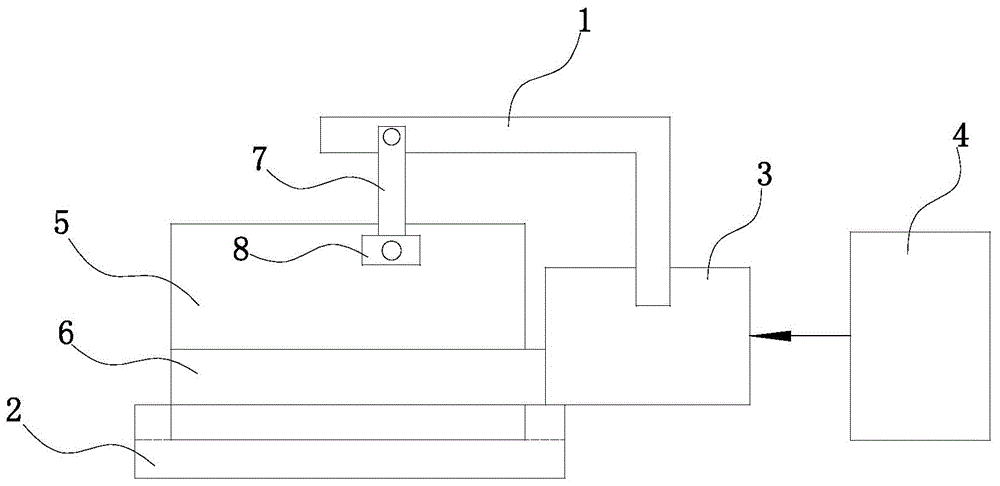

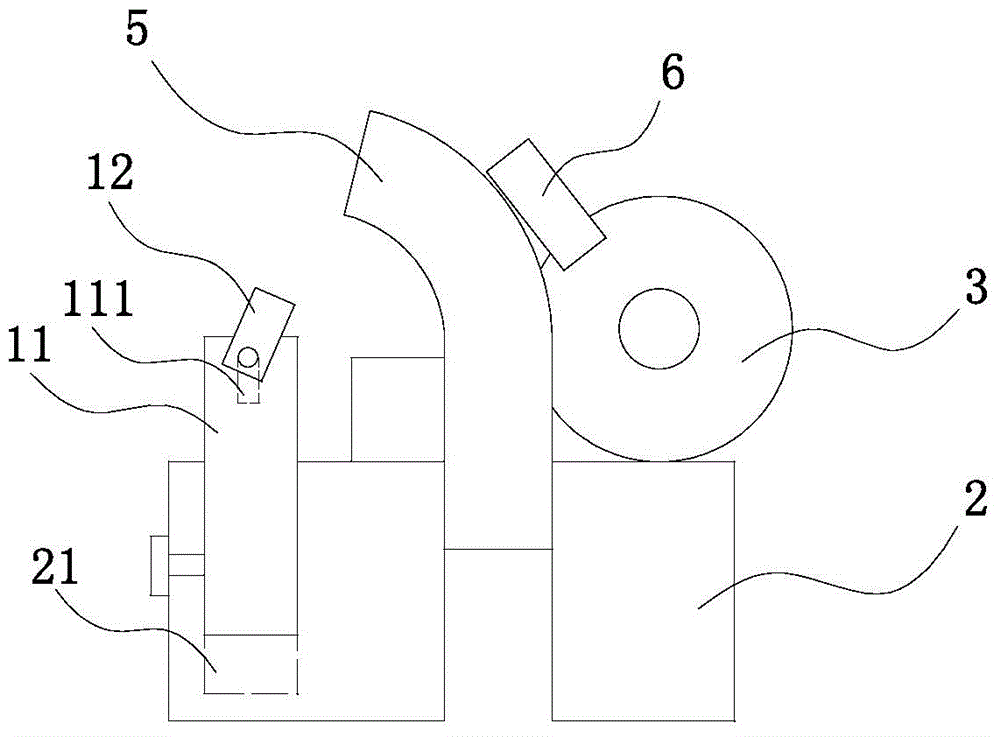

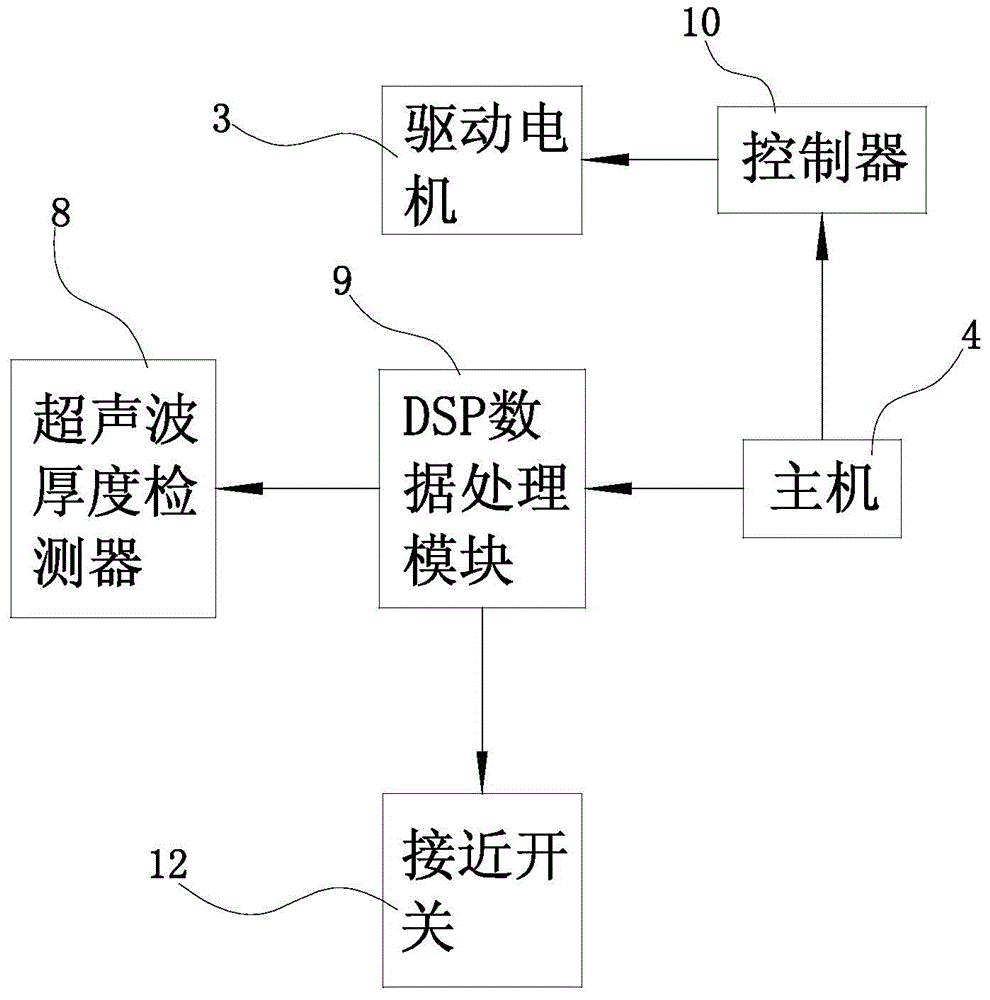

[0014] Such as figure 1 , figure 2 and image 3 As shown, the bending device based on intelligent adjustment and control in this embodiment includes a drive motor 3 installed on the frame 1, a clamping and fixing seat 2 and a host 4 that controls the drive motor 3, and the motor shaft of the drive motor 3 The bending shaft 6 is installed, and the device to be processed 5 is clamped on the fixed seat 2. It also includes an ultrasonic thickness detector 8 installed on the frame 1 by means of a bracket 7, and an ultrasonic thickness detector 8 installed in the clamping groove 21 of the clamped fixed seat 2. Support bar 11 and the controller 10 that is connected with main frame 4, the upper end of support bar 11 is connected proximity switch 12, and ultrasonic thickness detector 8 and proximity switch 12 are connected with main frame 4 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com