Palladium-carbon catalyst for preparing furan through furfural decarbonylation process, and preparation method thereof

A technology for decarbonylation to prepare furan and palladium-carbon catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve good stability, high selectivity, catalyst long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

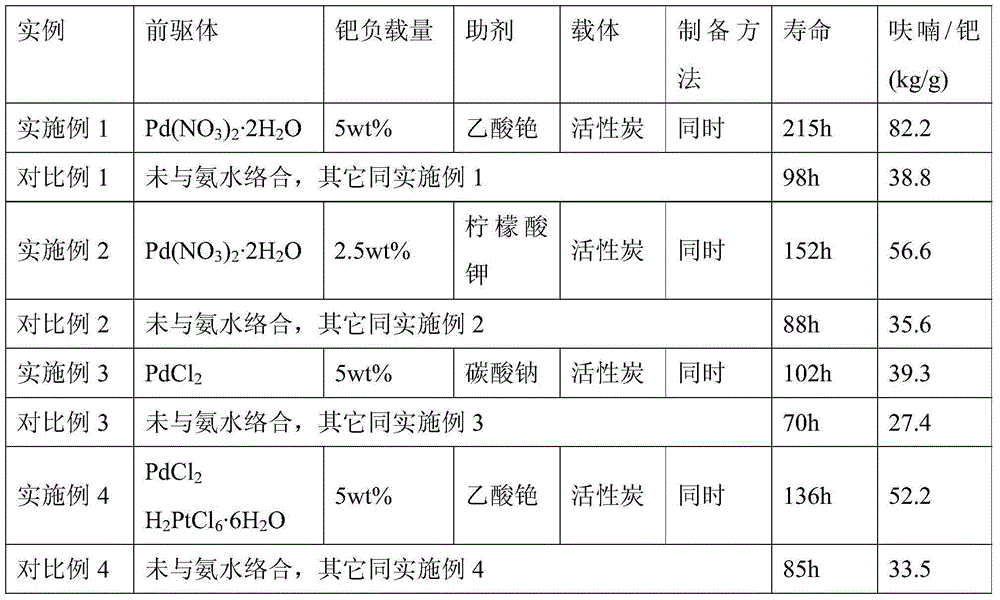

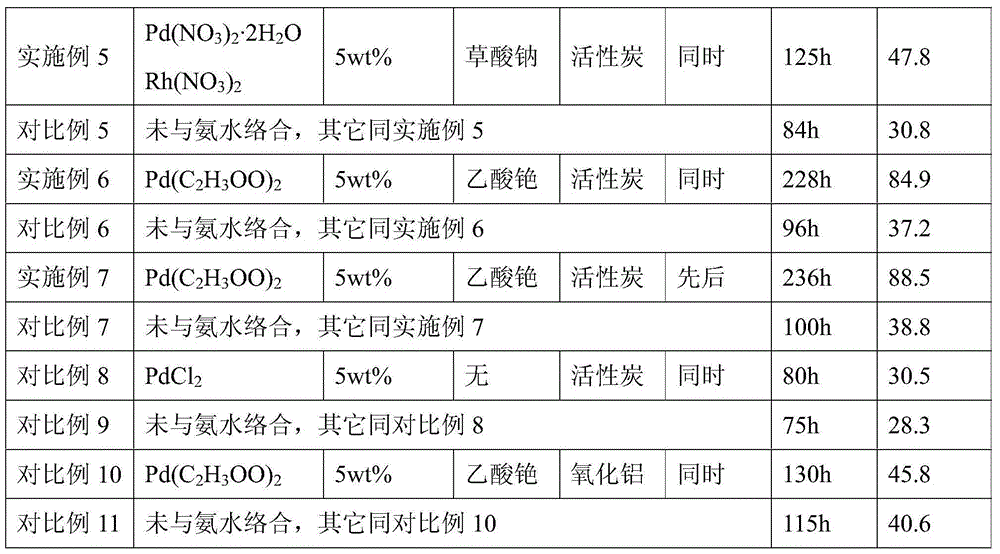

Examples

Embodiment 1

[0031] 1) Get 10g of activated carbon (dry weight) carrier, pretreat the activated carbon with nitric acid, wash with deionized water, and dry.

[0032] 2) 1.25gPd(NO 3 ) 2 2H 2O was mixed with ammonia water to prepare an aqueous solution of palladium ammonia complex (40 g), and 0.36 g of cesium acetate was added, mixed evenly, quickly added to the above-mentioned activated carbon, and stirred for 4.0 h.

[0033] 3) At 80°C, add 2ml of formaldehyde, and stir for reduction for 4h;

[0034] 4) Cool, let stand overnight, filter, wash with deionization until the filtrate is neutral, and obtain a 5% Pd / C catalyst with a water content of 61.5%.

Embodiment 2

[0036] 1) Get 10g of activated carbon (dry weight) carrier, pretreat the activated carbon with nitric acid, wash with deionized water, and dry.

[0037] 2) 0.63gPd(NO 3 ) 2 2H 2 O was mixed with ammonia water to prepare palladium ammonium complex aqueous solution (40 g), and 0.18 g of potassium citrate was added, mixed evenly, quickly added to the above-mentioned activated carbon, and stirred for 4.0 h.

[0038] 3) At 80°C, add 2ml of formaldehyde, and stir for reduction for 4h;

[0039] 4) Cool, let stand overnight, filter, wash with deionization until the filtrate is neutral, and obtain a 2.5% Pd / C catalyst with a water content of 59.5%.

Embodiment 3

[0041] 1) Get 10g of activated carbon (dry weight) carrier, pretreat the activated carbon with nitric acid, wash with deionized water, and dry.

[0042] 2) 0.83gPdCl 2 Mix it with ammonia water to prepare palladium ammonium complex aqueous solution (40g), add 0.36g sodium carbonate, mix well, quickly add to the above-mentioned activated carbon, and stir for 4.0h.

[0043] 3) At 80°C, add 2ml of formaldehyde, and stir for reduction for 4h;

[0044] 4) Cool, let stand overnight, filter, wash with deionization until the filtrate is neutral, and obtain a 5% Pd / C catalyst with a water content of 61.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com