Cervical anterior fixation system and manufacturing method thereof

A fixation system and anterior cervical spine technology, applied in the field of medical fixation systems and their preparation, can solve the problems of increasing the difficulty and time of surgery for doctors, prolonging the recovery period, non-degradable titanium alloy materials, etc., and eliminating the need for nut fixation and adjustment time. , Reduce the stress shielding effect, and achieve the effect of high-strength fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

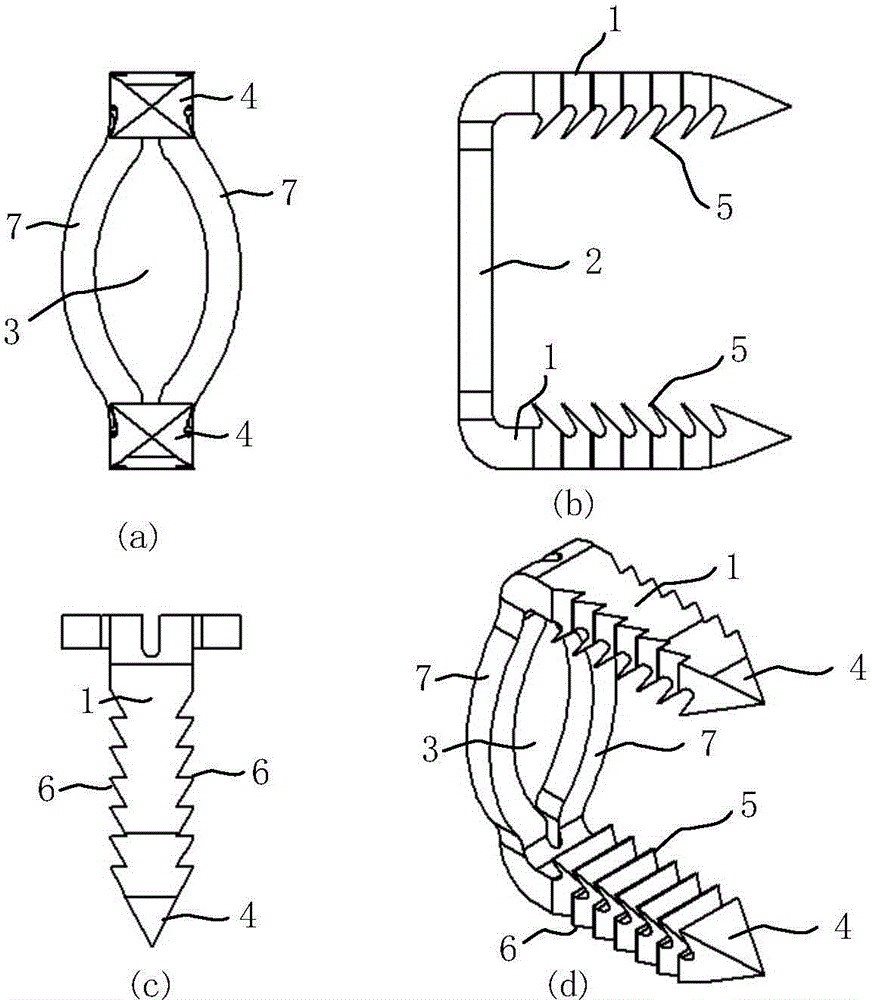

[0071] Please continue to see Figure 17 , the preparation method of cervical anterior approach internal fixation system provided by the present invention comprises the following steps:

[0072] Step S1: Integral processing of high-purity magnesium or magnesium alloy to form the fixed foot 1 and the fixed foot connecting rod 2; integrally process the fixed foot 1 and the fixed foot connecting rod 2 on the slow-moving wire cutting processing equipment, and the cut and formed The fixed foot 1 and the fixed foot connecting rod 2 are ground, polished and cleaned.

[0073] Step S2: place and soak the fixed foot 1 and the fixed foot connecting rod 2 after machining and surface cleaning in a mixed solution containing silicon salt; the mixed solution containing silicon salt is Na 2 SiO 3 9H 2 O, Na 3 PO 4 12H 2 Mixture of O and NaF, Na 2 SiO 3 9H 2 O, Na 3 PO 4 12H 2 O, KF and (CH 3 COO) 2 Ca·H 2 Mixture of O or K 2 SiO 3 9H 2 O, K 3 PO 4 12H 2 A mixture of O and ...

Embodiment 1

[0077] Three-dimensional software was used to design the shape and structure of the above-mentioned integrated anterior cervical internal fixation system, and the MB2 magnesium alloy material was used to process it on the wire cutting processing equipment, and then it was ground, polished, and cleaned for later use. at specific 14g / l Na 2 SiO 3 9H 2 O, 1g / l Na 3 PO 412H 2 O, 0.5g / l NaF mixed solution, use plasma oxidation equipment to treat at 470V for 5 minutes, and prepare a silicon-containing coating with a thickness of 15 microns.

Embodiment 2

[0079] Three-dimensional software is used to design the external structure of the above-mentioned integrated anterior cervical internal fixation system, and the pure magnesium material is used to process it on the slow-moving wire-cutting processing equipment, and then it is ground, polished, and cleaned for later use. at specific 12g / l Na 2 SiO 3 9H 2 O, 0.5g / l Na 3 PO 4 12H 2 O, 0.5g / l KF, 11g / l (CH 3 COO) 2 Ca·H 2 O mixed solution was treated with plasma oxidation equipment at a voltage of 450V for 6 minutes to prepare a silicon-containing coating with a thickness of 10 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com