Comprehensive aquatic product processing leftover utilization method

A technology for leftovers and aquatic products, applied in fish processing, crustacean processing, shrimp/lobster processing, etc., can solve problems such as difficulty in sustainable development of enterprises, and achieve the effects of product safety, high extraction rate and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

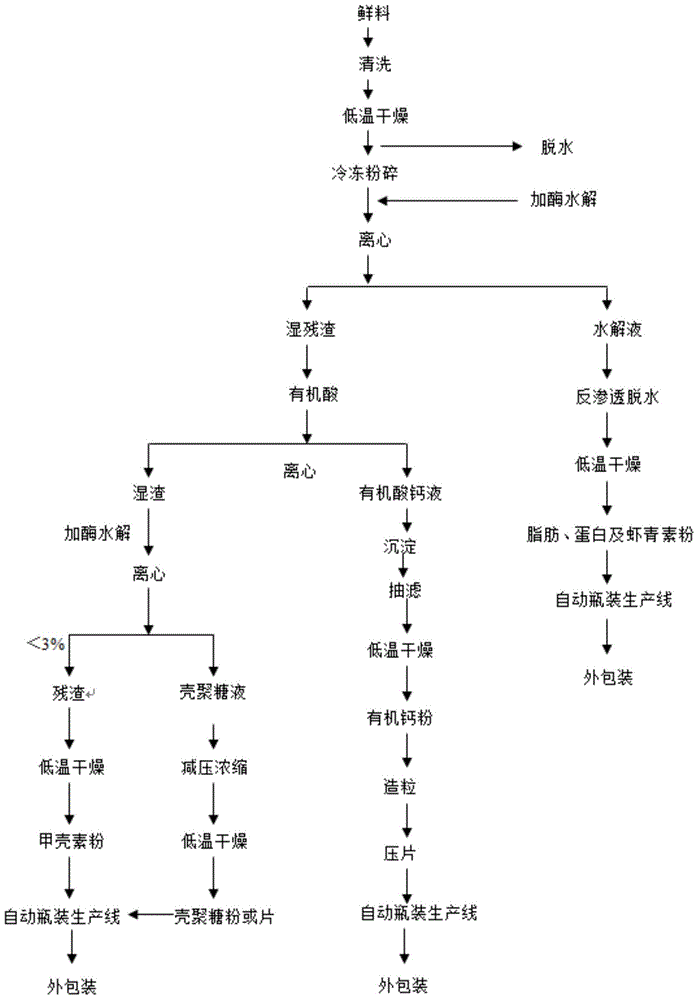

Image

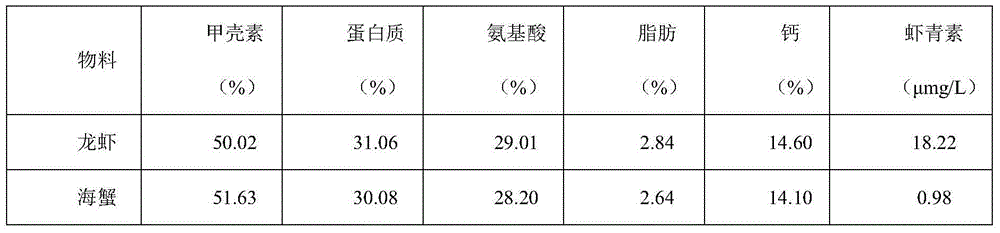

Examples

Embodiment 1

[0058] The concrete steps of the comprehensive utilization method of aquatic product processing leftovers of the present invention are as follows:

[0059] (1) Production of astaxanthin, fatty acid and hydrolyzed protein products:

[0060] 1.1 Wash the leftovers from aquatic product processing, dry them in a vacuum low-temperature freeze dryer at 40°C until the water content reaches 3%, freeze and crush them to 40 meshes;

[0061] 1.2 To the raw material treated in step 1.1, add water 6 times of the dry weight of the raw material, adjust the pH value to 7, add lipase and papain, the weight ratio of which is 0.2% and 0.4% of the weight of the substrate, hydrolyze for 6h, after hydrolysis After 1 hour, add 0.3% flavor enzyme according to the dry weight ratio of the substrate until the hydrolysis is completed;

[0062] 1.3 After deactivating the product of step 1.2, put it into a decanter centrifuge at 3000 rpm for 15 minutes for solid-liquid separation to obtain a solid phase a...

Embodiment 2

[0078] The concrete steps of the comprehensive utilization method of aquatic product processing leftovers of the present invention are as follows:

[0079] (1) Production of astaxanthin, fatty acid and hydrolyzed protein products:

[0080] 1.1 Wash the leftovers from aquatic product processing, dry them in a vacuum low-temperature freeze dryer at 50°C until the water content reaches 3%, freeze and crush them to 50 meshes;

[0081] 1.2 To the raw material treated in step 1.1, add water 8 times the dry weight of the raw material, adjust the pH value to 7, add lipase and papain, the weight ratio of which is 0.4% and 0.6% of the weight of the substrate, hydrolyze for 8h, after hydrolysis After 2 hours, add 0.4% flavor enzyme according to the dry weight ratio of the substrate until the hydrolysis is completed;

[0082] 1.3 After deactivating the product of step 1.2, put it into a decanter centrifuge at 3000 rpm for 15 minutes for solid-liquid separation to obtain a solid phase and...

Embodiment 3

[0098] The concrete steps of the comprehensive utilization method of aquatic product processing leftovers of the present invention are as follows:

[0099] (1) Production of astaxanthin, fatty acid and hydrolyzed protein products:

[0100] 1.1 Wash the leftovers from aquatic product processing, dry them in a vacuum low-temperature freeze dryer at 55°C until the water content reaches 3%, freeze and crush them to 60 mesh;

[0101] 1.2 To the raw material treated in step 1.1, add water 10 times the dry weight of the raw material, adjust the pH value to 7, add lipase and papain, the weight ratio of which is 0.4% and 0.5% of the weight of the substrate, hydrolyze for 7 hours, and then After 3 hours, add 0.5% flavor enzyme according to the dry weight ratio of the substrate until the hydrolysis is completed;

[0102] 1.3 After deactivating the product of step 1.2, put it into a decanter centrifuge at 3000 rpm for 15 minutes for solid-liquid separation to obtain a solid phase and a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com